Asphalt mixing system

A technology of asphalt mixing and stirring paddles, which is applied in the field of asphalt mixing systems, can solve problems such as large addition amount and adding speed, inability to continue stirring, and sticking of asphalt mixture, so as to achieve high heating efficiency, prevent heat loss, and prevent sticking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

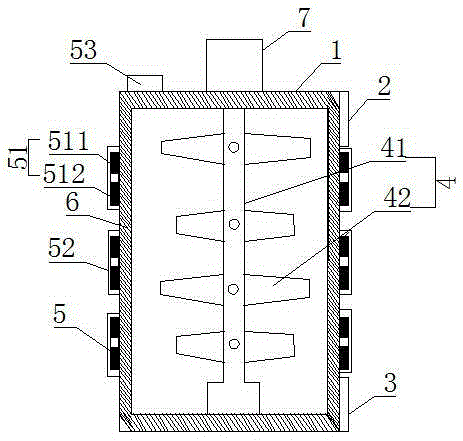

[0021] Reference attached figure 1 with attached figure 2 The embodiment of an asphalt mixing system of the present invention is further described;

[0022] An asphalt mixing system includes a pot body 1, a feeding door 2, a discharging door 3, a stirring device 4, and a heating device 5. The feeding door 2 is provided on the upper right of the pot body 1, and the pot body The discharge door 2 is provided at the lower right of the 1, and the inner wall of the pot body 1 is provided with a lining plate 6. During the stirring process, other materials such as sand and stone will cause a large amount of damage to the inner wall of the pot body. wear, and the heating device on the outer wall of the pot body 1 will cause slight deformation of the pot body 1 under the condition of high temperature, which is not conducive to the long-term use of the stirring system; the upper end of the pot body 1 is provided with a motor 7, The inside of the pot body 1 is provided with the stirrin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com