Heat-pipe type automobile brake disc cooling device

A technology of automobile brakes and cooling devices, which is applied to cooling brakes, vehicle components, transportation and packaging, etc., can solve problems such as corrosion, rust of the brake system, and performance degradation of friction materials, so as to ensure dynamic balance, improve brake safety, Good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

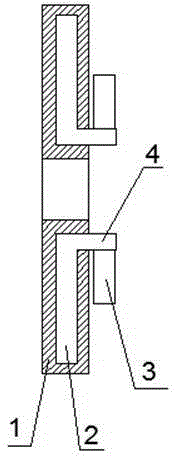

[0023] Specific implementation method: combined with figure 1 And attached figure 2 , to further explain the present invention.

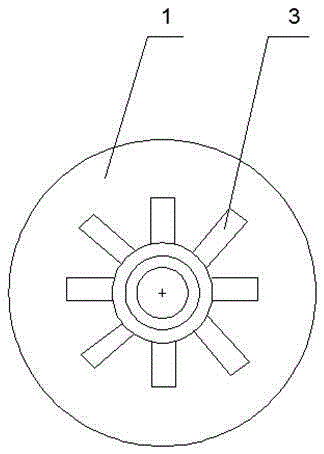

[0024] A heat pipe type automobile brake disc cooling device, comprising a brake disc (1), a heat pipe evaporation section (2), a heat dissipation fin (3), and a heat pipe condensation section (4); the inside of the brake disc (1) is hollow, and the hollow section It is L-shaped, the heat pipe evaporating section (2) and the heat pipe condensing section (4) constitute an L-shaped, L-shaped internal cavity is added with working fluid, and sealed after vacuuming, and the heat pipe condensing section (4) is welded with cooling fins ( 3).

[0025] The heat dissipation fins (3) are made of aluminum, and are evenly distributed in the circumferential direction, and the welding process is laser welding. figure 2 shown.

[0026] The heat pipe evaporation section (2) is located at the inner cavity of the brake disc (1) corresponding to the brake pad, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com