Systems and methods for detecting crack growth

A technique for detecting materials, crack propagation, applied in measuring devices, using optical devices, optical testing for flaws/defects, etc., to solve problems such as component or material damage, no indication at the end of cracks, imprecise components or materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

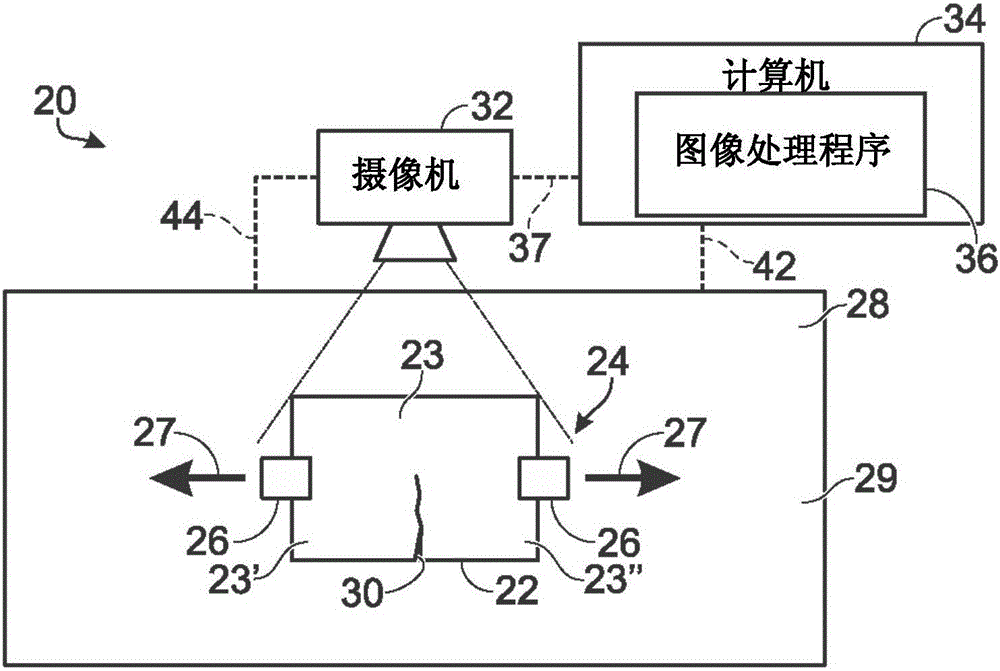

[0043] This example describes an illustrative crack growth detection system 20 and an illustrative test sample 22; see Figure 1-5 .

[0044] Test sample 22 may comprise a single component or may comprise multiple components. In some examples, a test sample may be a single sheet or a single plate that may include a bend or notch (eg, a cut). In other examples, test sample 22 may be a composite material having two or more constituent materials that have substantially different physical or chemical properties. For example, construction materials may include a matrix (or bond) material, such as a resin (eg, a thermoset epoxy) and a reinforcement material, such as a plurality of fibers (eg, a braid of carbon fibers). The test sample may include a surface 23 (such as a top surface), which may be a color contrasting surface. In some examples, surface 23 may include a color contrast coating 23'. The color contrast coating may be a film, paint (such as a spray paint), stain, varni...

example 2

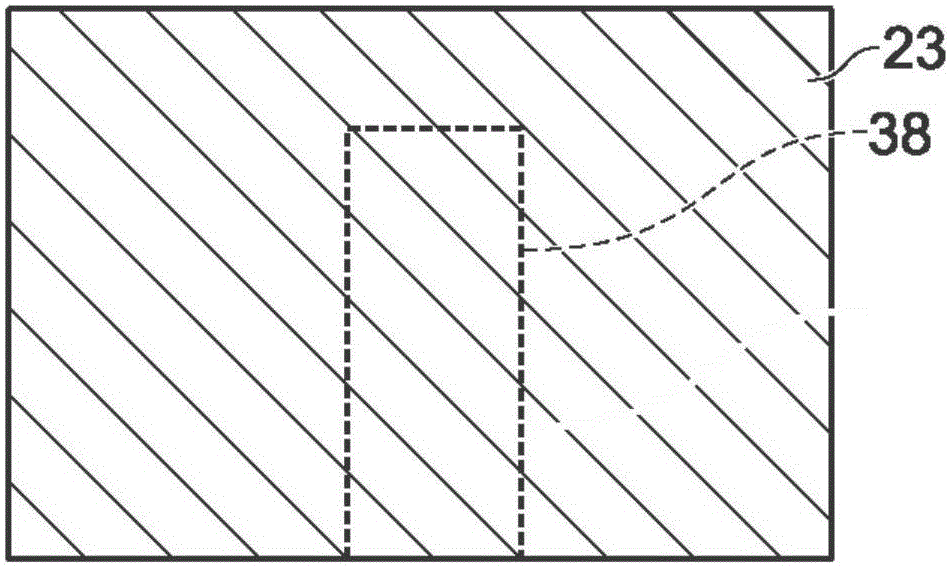

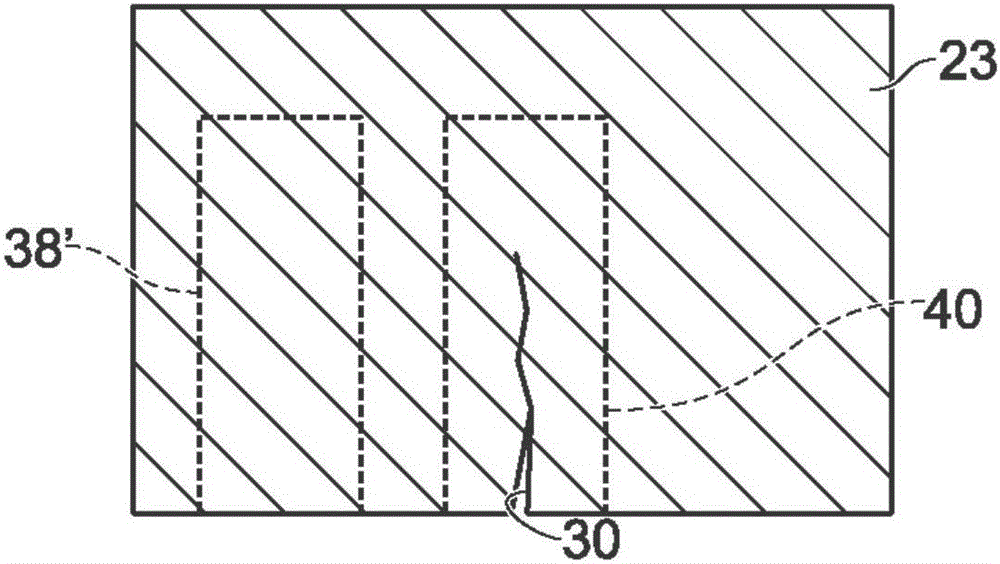

[0054] This example describes an image processing program 36 suitable for use with the crack growth detection system 20 as described in Example 1; see Figure 6-12 .

[0055] Image processing program 36 may be configured to determine pixel characteristics of photographic images, such as pixel intensity, hue, brightness, and saturation. For example, when the photographic image is a black and white image, the image processing program may be configured to determine the intensity of each pixel ranging from the lowest intensity black to the highest intensity white (such as a range from 0 to 255). When the photographic image is a color image, image processing program 36 may be configured to determine the intensity of each primary color, namely red, green and blue (RGB). For example, the determined intensity of each primary color may range from 0 to 255 with a 24-bit color scheme.

[0056] Figure 6-8 Illustrative results of the image processing program 36 analyzing the pixels 46 ...

example 3

[0072] This example describes the method used to detect crack growth in test samples of materials; see Figure 13 .

[0073] Figure 13 Depicted are steps of a method that may be performed in conjunction with crack growth system 20 in accordance with aspects of the present disclosure. While the various steps of method 100 are described below, and in Figure 13 are depicted in , but the steps are not necessarily all performed, and in some cases may be performed in an order different from that shown.

[0074] The method 100 may include a step 102 of color contrasting the surface of the test sample. Color contrasting the surface may include applying a color contrasting coating to the surface of the test sample, such as a painted surface. In some examples, the coating may exhibit a highly contrasting color relative to the surface color of the background. When the test sample comprises two or more layers, color contrasting the surface may include providing a color contrasting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com