Electrochemical battery and manufacturing method therefor

An electrochemical and battery technology, applied in the field of electrochemical batteries, can solve problems such as packaging failure, reduce the area, reduce the total amount of glue overflow, and save the amount of glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

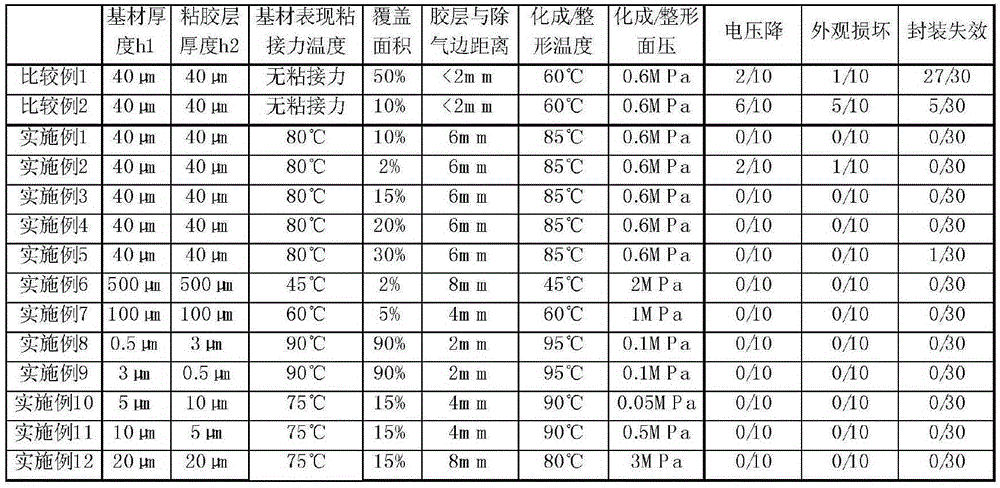

Examples

Embodiment 1

[0032] Embodiment 1, different from Comparative Example 2, this embodiment comprises the following steps:

[0033] Adhesive layer setting: select a modified polypropylene film with a thickness of 40 μm as the base material (adhesive force is exhibited when the temperature is 80° C.), and a polyurethane tape with a thickness of 40 μm is used as the adhesive layer; paste the tape on The surface of the above-mentioned bare cells, and the tape covers 10% of the surface area of the bare cells, and the distance between the tape and the side of the battery degassing package is 6mm; then put the bare cells in the outer packaging bag for top sealing and side sealing;

[0034] Finished battery preparation: Dry the above-mentioned top-sealed cells, inject liquid, and perform fixture formation at 85°C and 0.6 MPa after the electrolyte is fully infiltrated, and then shape, degas, and seal to obtain finished cells.

[0035]The rest are the same as those of Comparative Example 2, and will ...

Embodiment 2

[0036] Embodiment 2, different from Embodiment 1, this embodiment includes the following steps:

[0037] Adhesive layer setting: select a modified polypropylene film with a thickness of 40 μm as the base material (adhesive force is exhibited when the temperature is 80° C.), and a polyurethane tape with a thickness of 40 μm is used as the adhesive layer; paste the tape on The surface of the above-mentioned bare cells, and the tape covers 2% of the surface area of the bare cells, and the distance between the tape and the side of the battery degassing package is 6mm; then put the bare cells in the outer packaging bag for top sealing and side sealing;

[0038] The rest are the same as in Embodiment 1 and will not be repeated here.

Embodiment 3

[0039] Embodiment 3, different from Embodiment 1, this embodiment includes the following steps:

[0040] Adhesive layer setting: select a modified polypropylene film with a thickness of 40 μm as the base material (adhesive force is exhibited when the temperature is 80° C.), and a polyurethane tape with a thickness of 40 μm is used as the adhesive layer; paste the tape on The surface of the above-mentioned bare cells, and the tape covers 15% of the surface area of the bare cells, and the distance between the tape and the side of the battery degassing package is 6mm; then put the bare cells in the outer packaging bag for top sealing and side sealing;

[0041] The rest are the same as in Embodiment 1 and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com