Portable three-coordinate milling machine and machining method thereof

A processing method and three-coordinate technology, applied in the direction of milling machines, milling machine equipment, metal processing equipment, etc., can solve the problems of not meeting the production cycle requirements of Boring737MAX-IF inner flaps, not meeting the fatigue resistance performance requirements, and low technical level, etc. Achieve the effects of simple stepless speed regulation, compact structure and high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

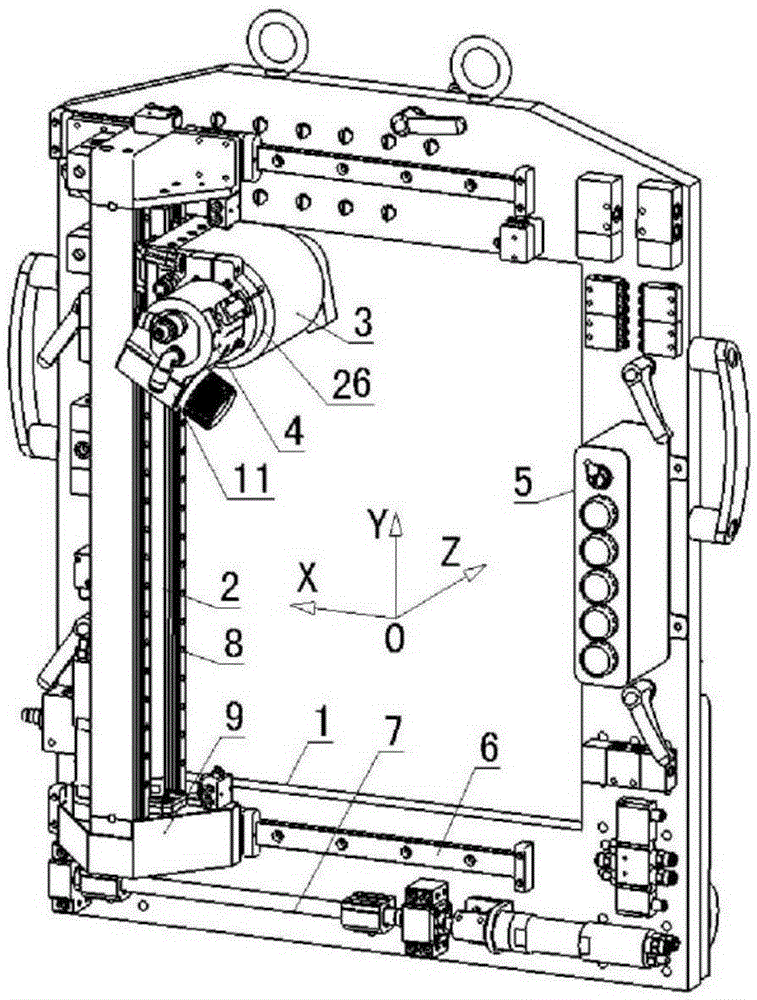

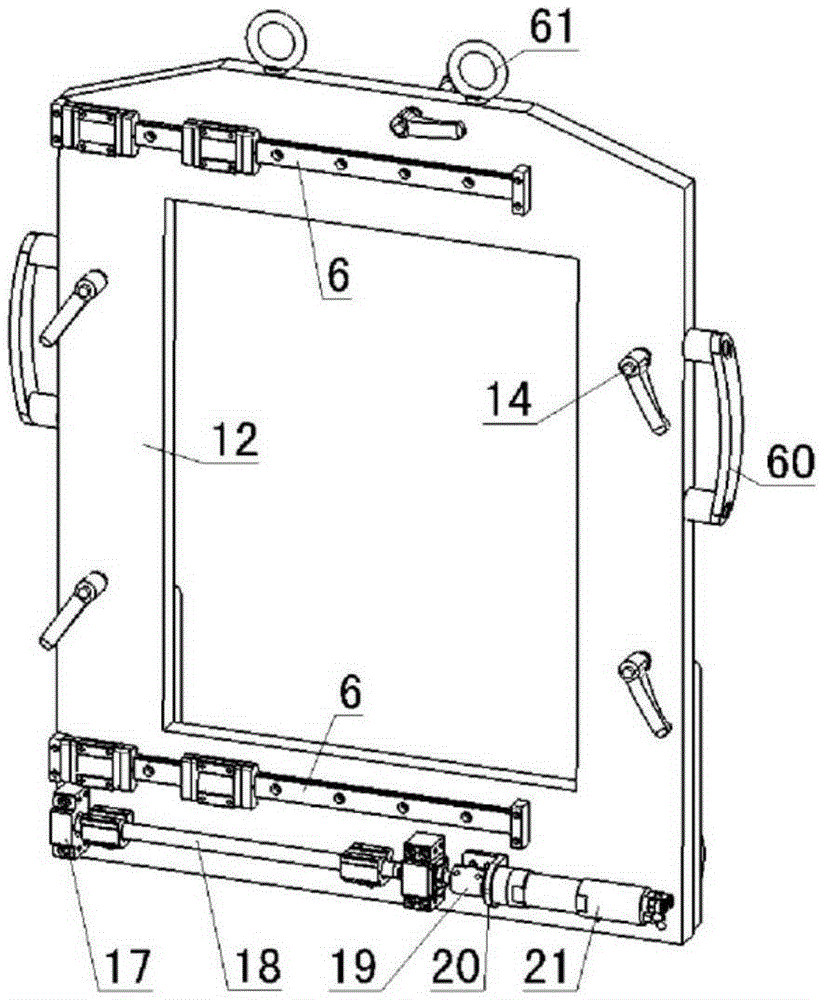

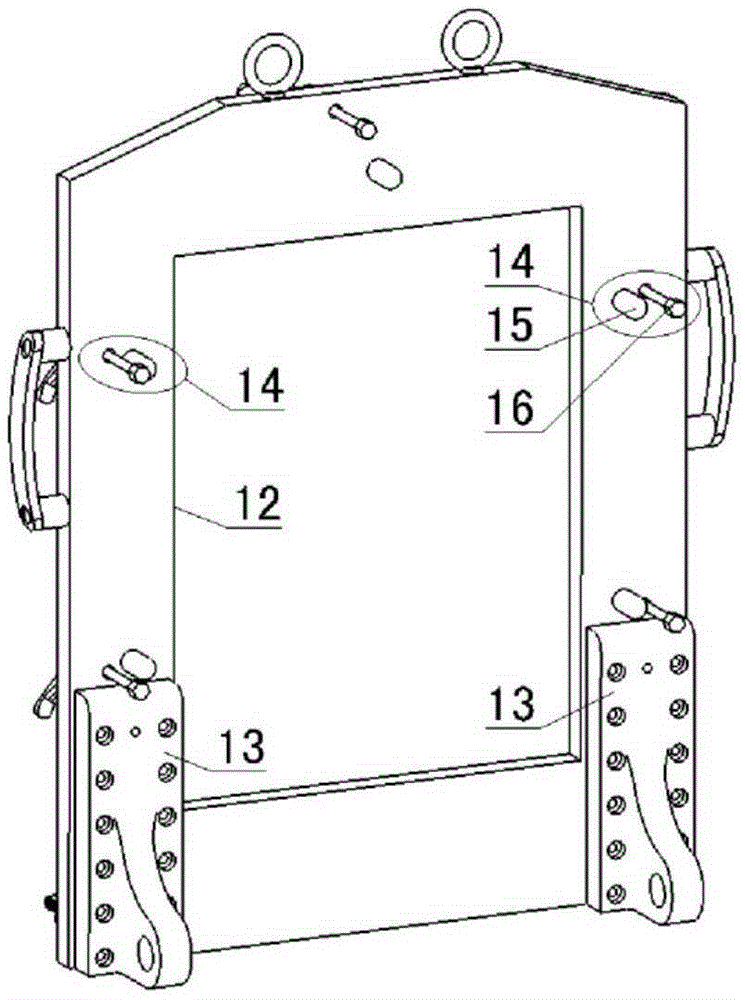

[0043] according to Figure 1-Figure 7 , a portable three-coordinate milling machine, which contains a flat panel assembly 1, a column assembly 2, a sliding table assembly 3, a milling head 4, and an integrated control system 5, and the flat panel assembly 1 includes a flat panel 12, a hinge seat 13, a pretension assembly 14. X-guiding rail 6, X-directing transmission mechanism 7, the flat plate 12 is a back-shaped rectangular plate with an opening in the middle, two parallel X-guiding rails 6 are installed at the corresponding positions on the upper and lower parts of the front of the flat plate 12, one of the lower An X-direction transmission mechanism 7 is installed below the X-guiding rail 6; on the opposite side of the flat plate 12, a pair of parallel and coaxial hinge seats 13 are installed diagonally at the bottom, and a plurality of pre-tightening assemblies 14 are evenly arranged on the top along the edge of the opening. It is used to fix the portable three-coordinat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com