Uniform feeding device and method for unshelling processing of small shrimps

A feeding device and small-scale technology, applied in the direction of transportation and packaging, conveyors, mechanical conveyors, etc., can solve the problems of reduced processing efficiency, product quality, and uneven blanking of shrimp shelling processing machines, so as to avoid processing The effect of product quality reduction, smooth unloading, and high-efficiency feeding equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

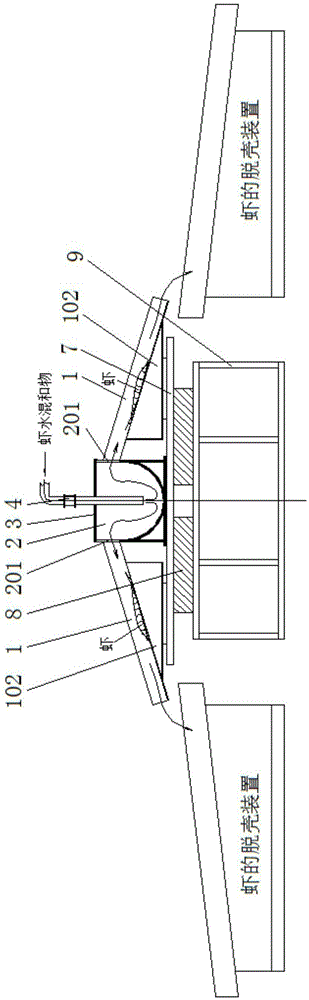

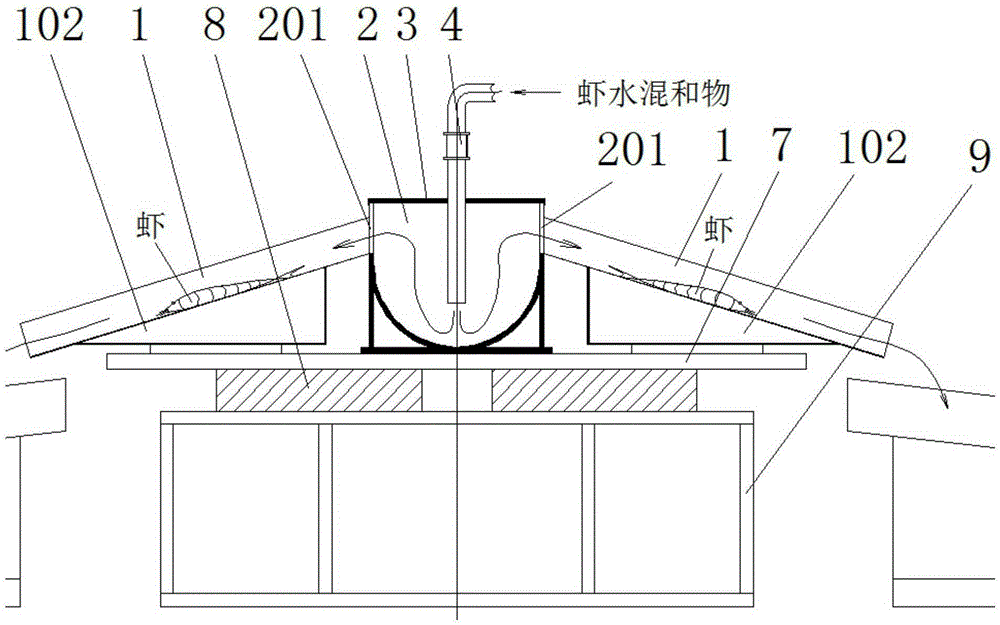

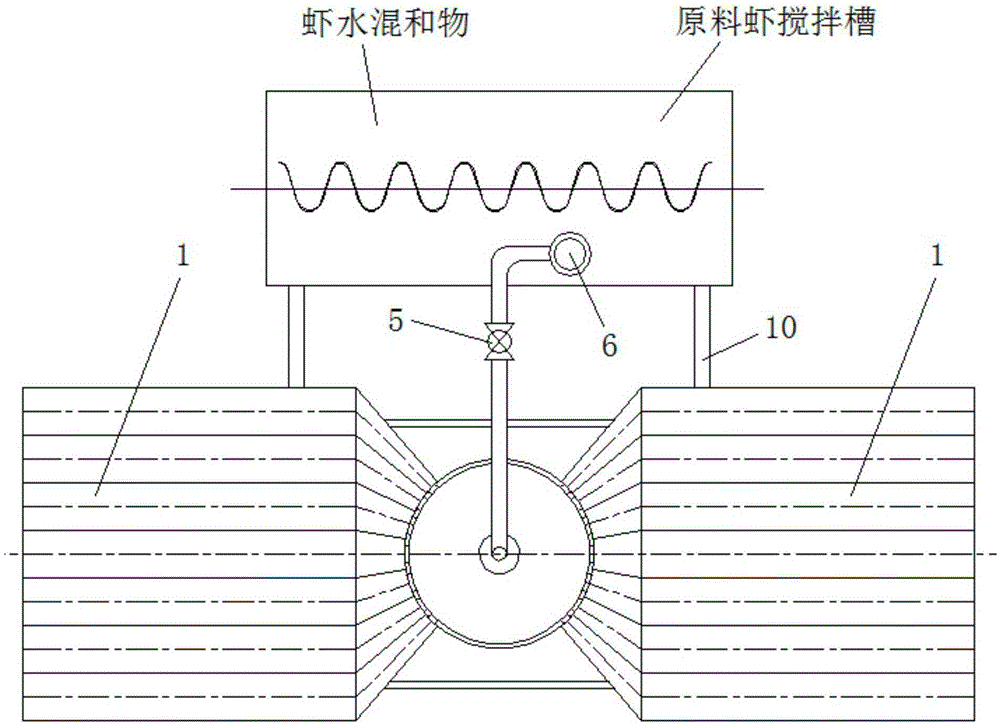

[0034] see Figure 1-Figure 7 , a homogeneous feeding device for shelling processing of small shrimps, comprising an integrated device for inclined guide grooves 1, a pot-shaped bottom material barrel 2, a discharge pipe, a pot-shaped bottom material barrel top cover 3, and a vibration-damping telescopic tube Section 4, flow control valve 5, raw material shrimp delivery pump 6, common base 7, electric vibrator 8, shared frame 9 and water filtration return pipeline system 10; Set the guide trough integrated device 1, they are arranged on a common base 7, the electric vibrator 8 is fixed with the common base 7, and is installed and fixed on the shared frame 9; Feed pipe, the lower part is inserted in the pot-shaped bottom material barrel 2, the upper part is connected with the shock-absorbing telescopic pipe joint 4, and the flow control valve 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com