Benzoxazine/epoxy resin/oxidized graphene composite material and preparation method thereof

A technology of benzoxazine and epoxy resin, which is applied in the field of benzoxazine/epoxy resin/graphene oxide composite material and its preparation, can solve the problem of high curing temperature and achieve lower curing temperature and high heat resistance index , the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Step 1, dissolving 0.007 g of graphene oxide in ethanol, and then treating it with an ultrasonic wave with a power of 300-800 watts for 2 hours to prepare a graphene oxide solution with a concentration of 0.01 g / L.

[0028] Step 2: Weigh 15 g of benzoxazine intermediate, 3 g of epoxy resin, and add 42 g of ethanol to prepare benzoxazine-epoxy resin solution.

[0029] Step 3, adding the benzoxazine-epoxy resin solution into the graphene oxide ethanol solution, stirring for 30 minutes to disperse it evenly, and then using the ultrasonic treatment in step 1 for 1 hour to obtain the benzoxazine / epoxy resin / graphene oxide mixture.

[0030] Step 4, put the benzoxazine / epoxy resin / graphene oxide mixture prepared in step 3 into a vacuum oven at 50°C, and dry the ethanol in the mixture to obtain benzoxazine / epoxy resin / graphene oxide Graphene oxide composite material intermediate.

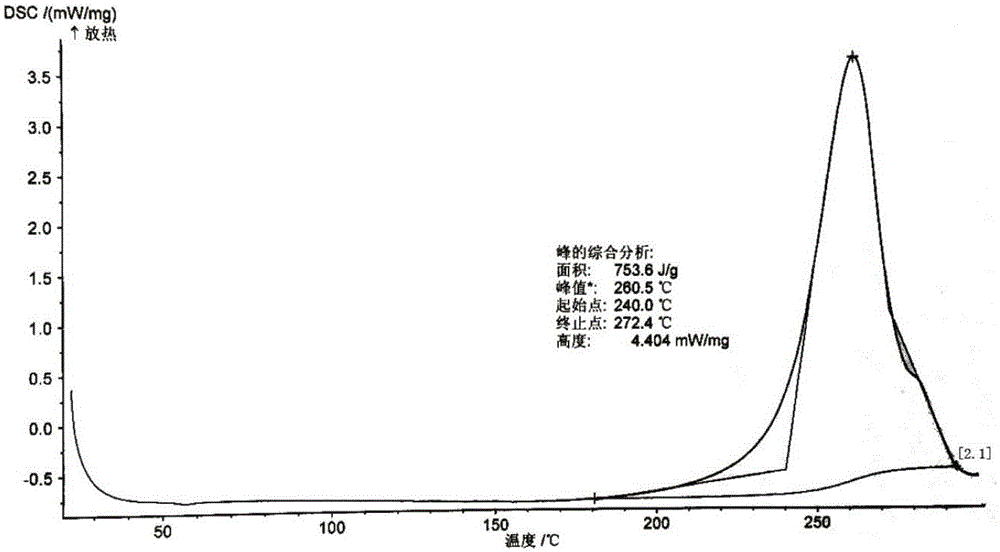

[0031] Step 5, curing the benzoxazine / epoxy resin / graphene oxide composite materi...

Embodiment 2

[0034] Step 1, dissolving 0.45 g of graphene oxide in ethanol, and then treating it with an ultrasonic wave with a power of 300-800 watts for 3 hours to prepare a graphene oxide solution with a concentration of 20 g / L.

[0035] Step 2: Weigh 15 g of benzoxazine intermediate, 30 g of epoxy resin, and add 105 g of ethanol to prepare benzoxazine-epoxy resin solution.

[0036] Step 3, adding the benzoxazine-epoxy resin solution into the graphene oxide ethanol solution, stirring for 30 minutes to disperse it evenly, and then using ultrasonic treatment in step 1 for 2 hours to obtain benzoxazine / epoxy resin / graphene oxide mixture.

[0037] Step 4, put the benzoxazine / epoxy resin / graphene oxide mixture prepared in step 3 into a vacuum oven at 90°C, and dry the ethanol in the mixture to obtain benzoxazine / epoxy resin / graphene oxide Graphene oxide composite material intermediate.

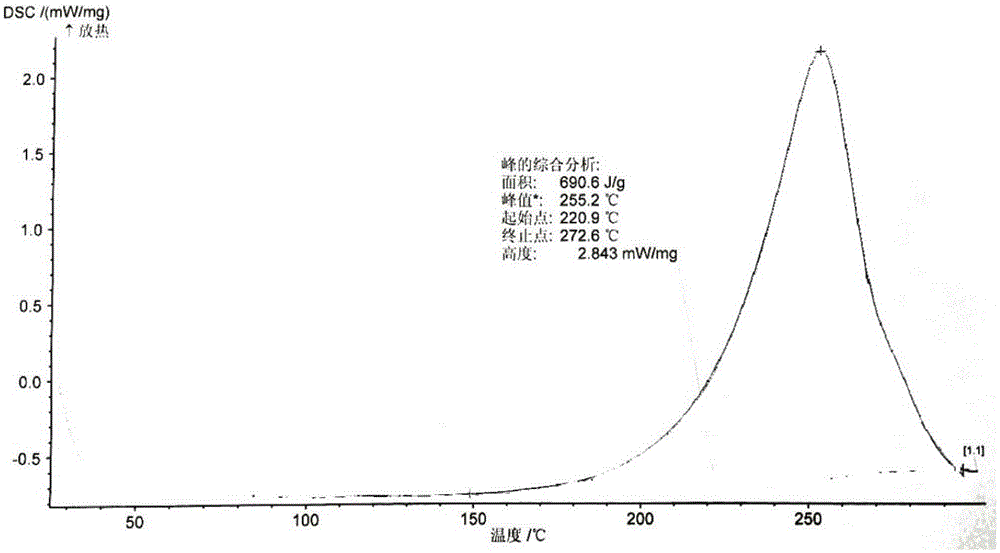

[0038] Step 5, curing the benzoxazine / epoxy resin / graphene oxide composite material inter...

Embodiment 3

[0041] Step 1, dissolving 0.01 g of graphene oxide in ethanol, and then treating it with an ultrasonic wave with a power of 300-800 watts for 1 hour to prepare a graphene oxide solution with a concentration of 0.1 g / L.

[0042] Step 2, weigh 15 g of benzoxazine intermediate, 15 g of epoxy resin, and add 70 g of ethanol to prepare benzoxazine-epoxy resin solution.

[0043] Step 3, adding the benzoxazine-epoxy resin solution into the graphene oxide ethanol solution, stirring for 30 minutes to disperse it evenly, and then using ultrasonic treatment in step 1 for 3 hours to obtain benzoxazine / epoxy resin / graphene oxide mixture.

[0044] Step 4, put the benzoxazine / epoxy resin / graphene oxide mixture prepared in step 3 into a vacuum oven at 70°C, and dry the ethanol in the mixture to obtain benzoxazine / epoxy resin / graphene oxide Graphene oxide composite material intermediate.

[0045] Step 5, curing the benzoxazine / epoxy resin / graphene oxide composite material interm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com