Leading cable of electric motor

A motor lead and cable technology, applied in the field of cable structure and lead cable structure, can solve problems such as partial discharge, and achieve the effects of low cost, thin insulation, and easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

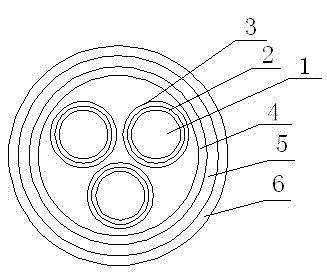

[0010] A motor lead cable is composed of a conductor 1 , an inner insulating layer 2 , an anti-corona layer 3 , an outer insulating layer 4 , an aluminum tape layer 5 and an outer sheath 6 . The conductor 1 is formed by stranded copper wires, and the inner insulating layer 2 of cross-linked polyethylene is extruded, and the anti-corona layer 3 of polyimide film is wrapped on the inner insulating layer, and the outer insulating layer 4 is extruded on the anti-corona layer. , Wrap the aluminum tape layer 5 on the outer insulating layer, and extrude the fluoroplastic outer sheath 6 on the aluminum tape layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com