Method for size renovation of aerospace parts

A technology of parts and size, applied in the field of repairing the size of aviation parts, can solve the problems affecting the quality of product maintenance, large capital investment, complex process and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

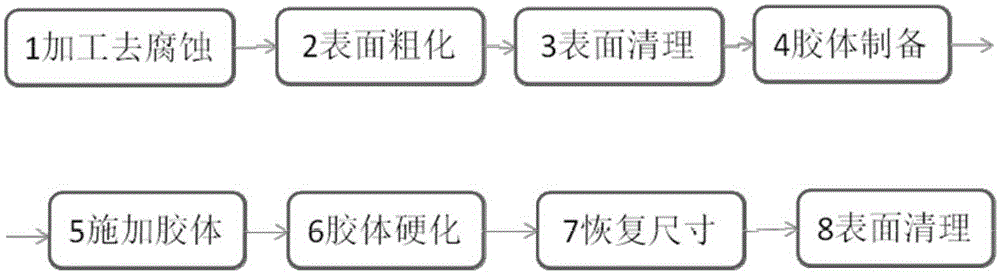

Method used

Image

Examples

Embodiment 1

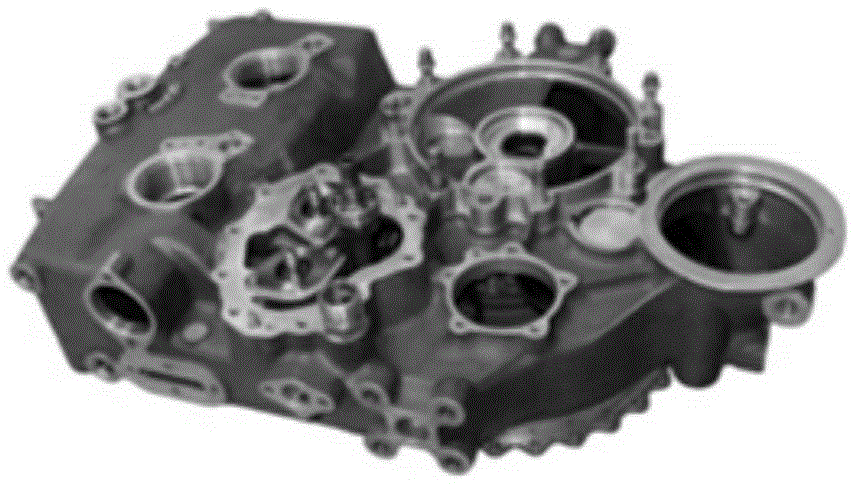

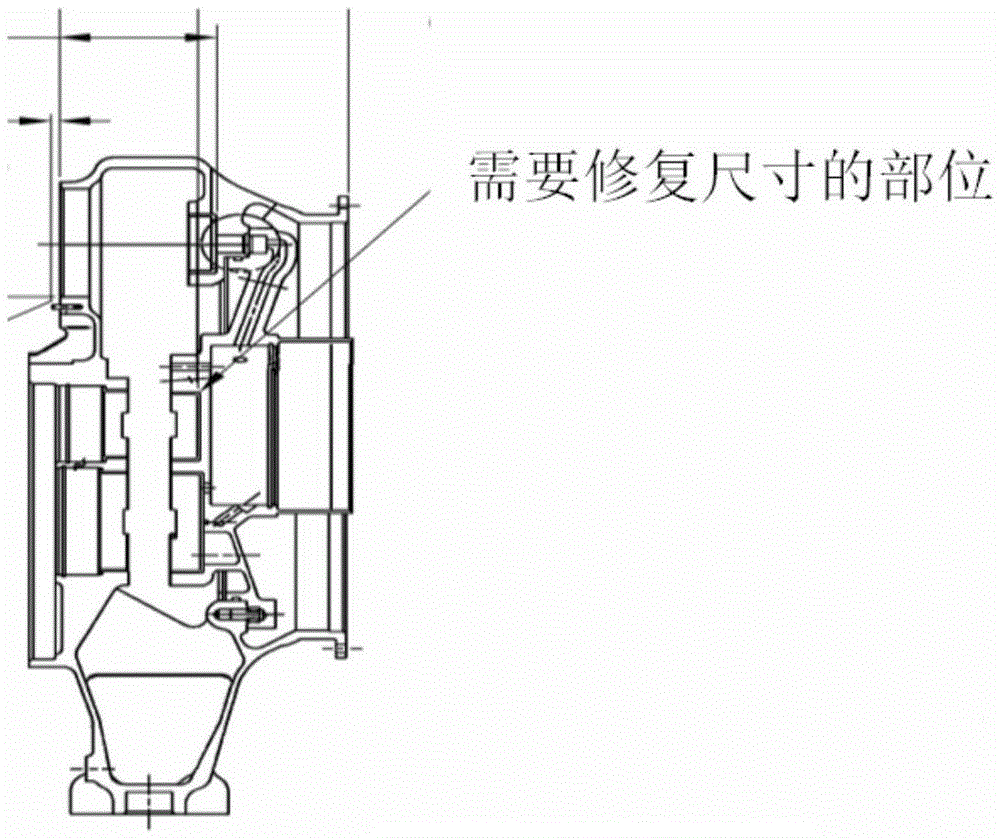

[0028] The application of wear-resistant epoxy materials in factory repairing aviation parts size method parts such as figure 2 , image 3 shown. This part is the gearbox casing of the aviation turbine starter. The position marked by 3 in the figure is the place where the size of the part is insufficient due to the hole on the casing worn by its shaft during work, and it needs to be repaired to restore the size. The quality requirement for the wear part is to have a certain hardness and at the same time have grindability.

[0029] Follow the steps below to fix it:

[0030] 1) Machining to remove surface corrosion

[0031] Turning to remove the surface corrosion of the parts to be repaired until the metal matrix is completely exposed;

[0032] 2) Surface roughening

[0033] Use the method of sand blowing to roughen the surface of the parts, and the sand grains should be within the range of 120-220 mesh;

[0034] 3) Surface cleaning and finishing

[0035] Clean the sur...

Embodiment 2

[0045] The technical solution of embodiment 2 is basically the same as that of embodiment 1, the difference lies in step 6) colloid solidification: solidify at a temperature of 100° C. in an air heating furnace for 1 hour, then naturally cool to room temperature, and place for processing after 1 day.

Embodiment 3

[0047]The technical scheme of embodiment 3 is basically the same as that of embodiment 1, the difference lies in step 6) colloid solidification: solidify at a temperature of 160° C. in an air heating furnace for 1 hour, then naturally cool to room temperature, and place for processing after 1 day.

[0048] For the above scheme, the test piece is taken in the factory, and the simulation test is carried out according to the corresponding working conditions. After passing the vibration test and thermal shock test, the appearance and structure are normal and meet the use requirements. After destructive inspection, it was found that the bonding surface reached 100%, and the inside of the grinding sealing layer was free of pores and voids.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com