A Low Infrared Characteristic Lobe Ejection and Mixing Device for Binary Nozzle Outlet

A binary nozzle and mixing device technology, applied in the direction of jet propulsion devices, machines/engines, etc., can solve the problems of limited cold air flow, no ejection channel for cold air flow, and limited suppression effect, so as to reduce resistance, The effect of reducing the intensity of infrared radiation and lowering the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

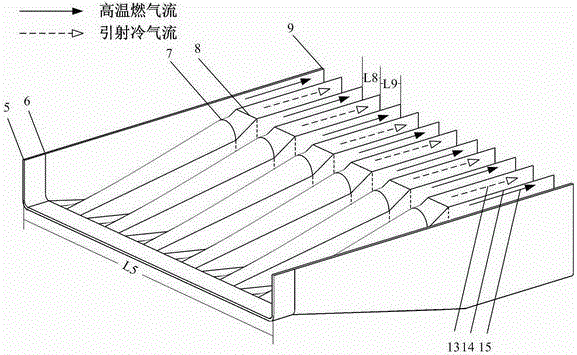

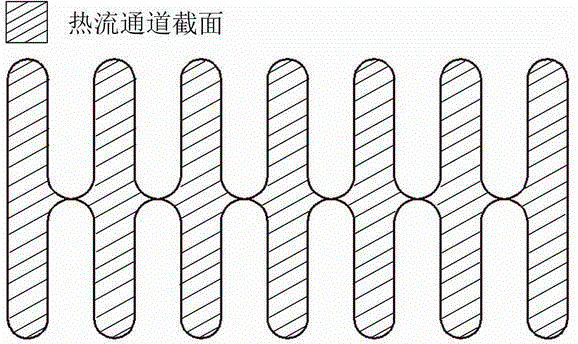

[0044] Set the logarithm n of the outer expansion lobe to 6, then the logarithm of the inner expansion lobe is 5; the logarithm of the outer expansion lobe is 1.5 times the aspect ratio, then the aspect ratio AR is 4 and the width is L5 Take 1.44m; then the equivalent diameter of the entrance of the rectangular transition section 1 is 0.576, and the area A1 of the entrance section 5 is 0.5184m 2 .

[0045] The area A2 of the exit section of the lobe section 2 and the entrance area of the rectangular transition section is equal to 0.5184m 2 , Lobe transition section 3 exit section 8 area A3 is twice the entrance area of rectangular transition section, namely 1.0368m 2 , The area A4 of the outlet section 9 of the separated cold and hot flow passage section 4 is equal to it.

[0046] In terms of length dimension, the axial length L1 of the rectangular transition section 1 is 0.1 times the equivalent diameter of the entrance of the rectangular transition section 1, which is 0.0576m....

Embodiment 2

[0048] Set the logarithm n of the outer expansion lobe to 12 pairs, then the logarithm of the inner expansion lobe is 11; the inlet equivalent diameter of the rectangular transition section 1 is 0.576, the aspect ratio AR is 4, and the width L5 is 1.44m.

[0049] According to the above data, the area A1 of the entrance section 5 is 0.5184m 2 , The area A2 of the exit section 7 of the lobe section 2 is the same as that of 0.5184m 2 , The area of the exit section of the lobe transition section 3 and 8 area A3 is 1.0368m 2 ,Separated cold and hot flow channel section 4 exit section 9 area A4 is 1.0368m 2 .

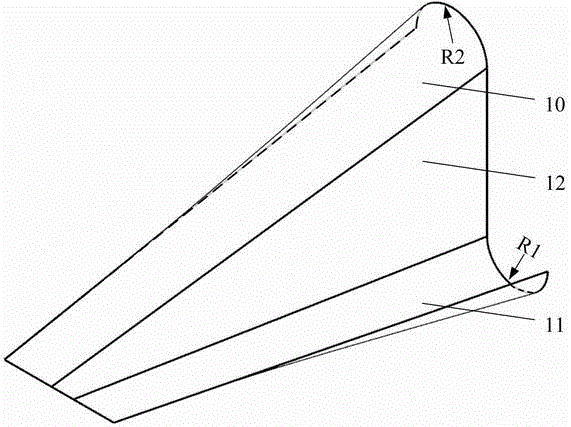

[0050] In terms of length dimensions, the axial length L1 of the rectangular transition section 1 is 0.144m, the axial length L2 of the lobe section 2 is 0.6912m, the axial length L3 of the lobe transition section 3 is 0.1152m, and the separated cold and hot flow channel section 4 The axial length L4 is taken as 0.3456m, the radius R1 at the end of the outer expansion lobe 11 is ...

Embodiment 3

[0052] Set the logarithm n of the outer expansion lobe to 9 pairs, then the logarithm of the inner expansion lobe is 8; the inlet equivalent diameter of the rectangular transition section 1 is taken as 0.576, and the area A1 of the inlet section 5 is taken as 0.5184m 2 , The aspect ratio AR is 4, and the width L5 is 1.44m.

[0053] Lobe section 2 exit section 7 area A2 is 0.5184m 2 , The area of the exit section 8 of the lobe transition section 3 is 1.0368m 2 ,Separated cold and hot flow channel section 4 exit section 9 area A4 is 1.0368m 2 .

[0054] The axial length L1 of the rectangular transition section 1 is 0.103m, the axial length L2 of the lobe section 2 is 0.5042m, the axial length L3 of the lobe transition section 3 is 0.0808m, and the axial length L4 of the split cold and hot flow channel section 4 is taken 0.2882m, the radius R1 of the end of the outer expansion lobe 11 is 0.04m, the radius of the end of the inner expansion lobe 10 is R2 is 0.045m; the height of the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com