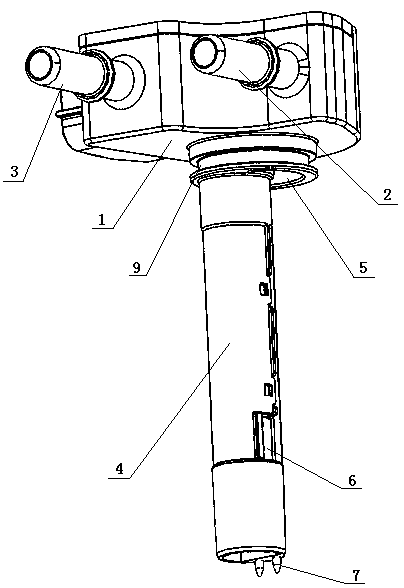

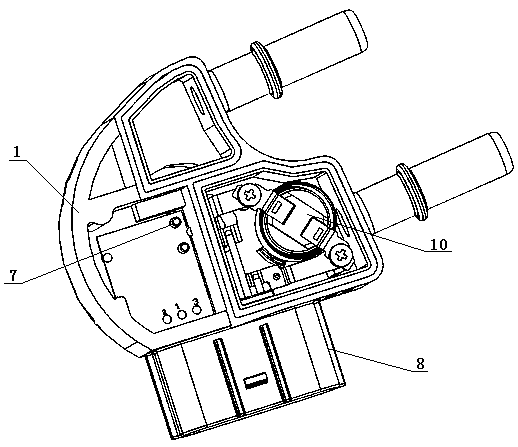

An integrated filter fuel heating and water level sensing device

A technology of water level sensing and water level sensor, which is applied in the direction of fuel heat treatment device, measuring device, lubrication indicating device, etc., can solve the problems of space occupation and cumbersome assembly, achieve accurate sensing, avoid heat waste, and improve heat utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

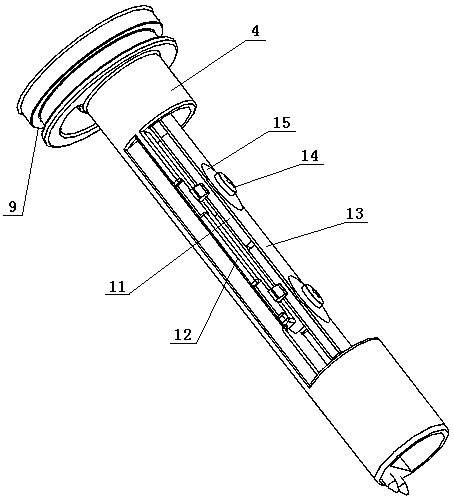

[0037] After the two heating plates are connected in parallel with the temperature controller, they are installed in the housing and the PTC heating plate and the two electrode plates are pressed against the support column of the housing with screws and spring washers to form a heater assembly. The two leads of the module are led out from the wiring port through two electrode poles, one of the pole poles is connected in series with the bimetallic temperature controller and then used as the positive connection of the external power supply through a connecting piece, and the other pole is extended out as the negative connection of the external power supply . The two electrode columns are smashed into the connector through interference fit, so as to connect to the vehicle power supply, which can be easily docked with the body harness.

[0038] When the diesel is flowing through the filter, the diesel will fill the entire filter tank. First, the metal temperature sensor of the temper...

Embodiment 2

[0041] Connect multiple heating plates in parallel, and then connect them in series with the temperature control, and put them into the shell, and use screws and spring washers to press the PTC heating plate and the two electrode plates on the supporting column of the shell to form a heater assembly . The other structure and connection relationship are the same as the technical solution in the first embodiment to realize fuel heating and water level monitoring at the bottom of the filter tank.

[0042] Specific implementation steps: First, install the heater assembly on the fixing hole of the housing with screws, and install the two electrode columns of the heater assembly into the connector integrated with the housing through interference fit, and then connect the vehicle power supply . The two electrodes of the heater assembly are then potted with epoxy resin after interference fit. The above two sealing methods are used for double protection, which is safer. It not only ensur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com