Dynamic braking device of crane

A braking device and crane technology, applied in mechanical equipment, drum brakes, brake types, etc., can solve the problems of aggravating the load of the traveling gearbox, affecting the production progress, dangerous product loading and unloading, etc., to achieve good braking performance, safe and convenient loading and unloading. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

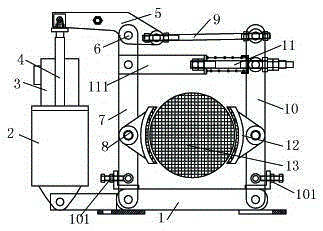

[0013] Combine below figure 1 and figure 2 Specific description embodiment:

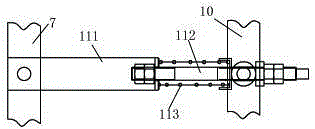

[0014] Such as figure 1 and figure 2 As shown, the dynamic braking device of the crane includes a base plate 1 and an oil pump 2, the oil pump 2 is connected with an oil pump motor 3 and an oil pump ejector rod 4, and the end of the oil pump ejector rod 4 is connected with one end of a working block 5, The working block 5 is hingedly connected to the second bracket 7 through the pin shaft 6. The working block 5 can rotate around the pin shaft 6 under the action of the oil pump ejector rod 4. The other end of the second bracket 7 is arranged on the bottom plate 1. The second bracket 7 is provided with a second brake pad assembly 8; the other end of the working block 5 is connected with a jack screw 9, and the jack screw 9 is connected to the first bracket 10, and the first bracket 10 The other end is arranged on the base plate 1, the first bracket 10 and the second bracket 7 are respectively arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com