Automatically-controlled high-heat-efficiency biological particle melting furnace

A biological particle and high thermal efficiency technology, applied in furnaces, crucible furnaces, waste heat treatment, etc., can solve the problems of large amount of biological particle fuel, no automatic control, low thermal efficiency, etc., to save fuel, improve use safety, and improve thermal efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

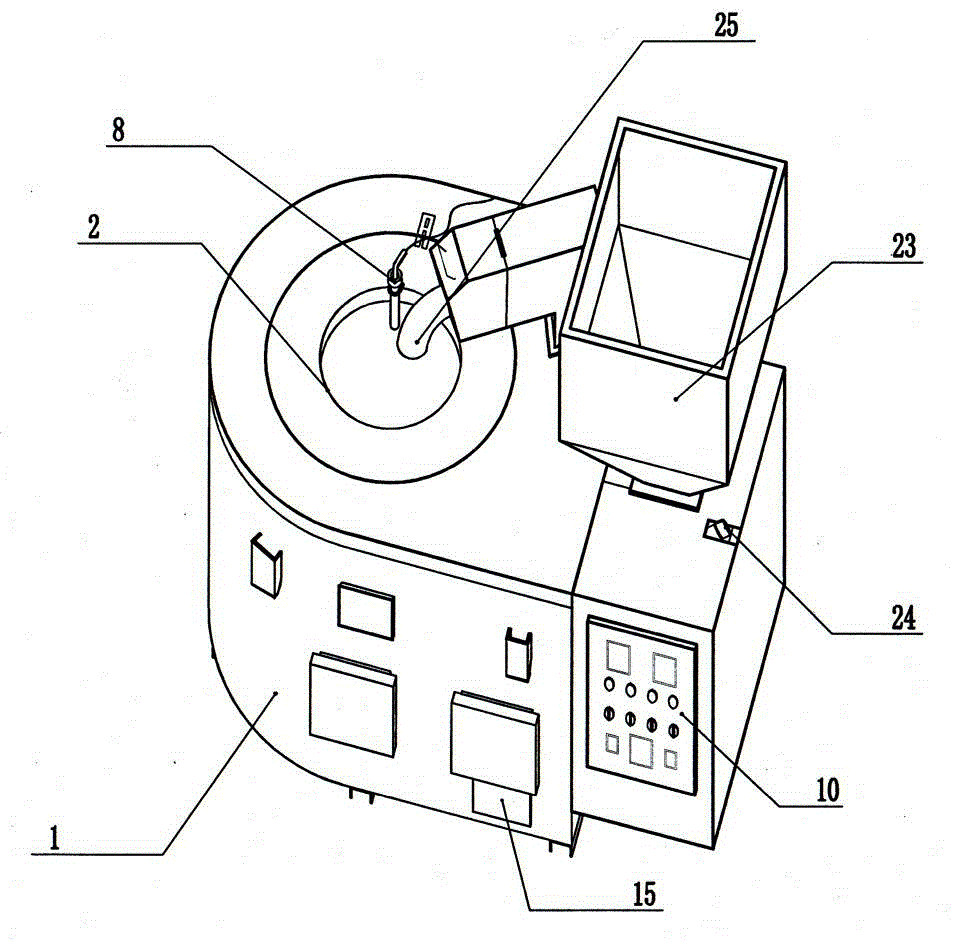

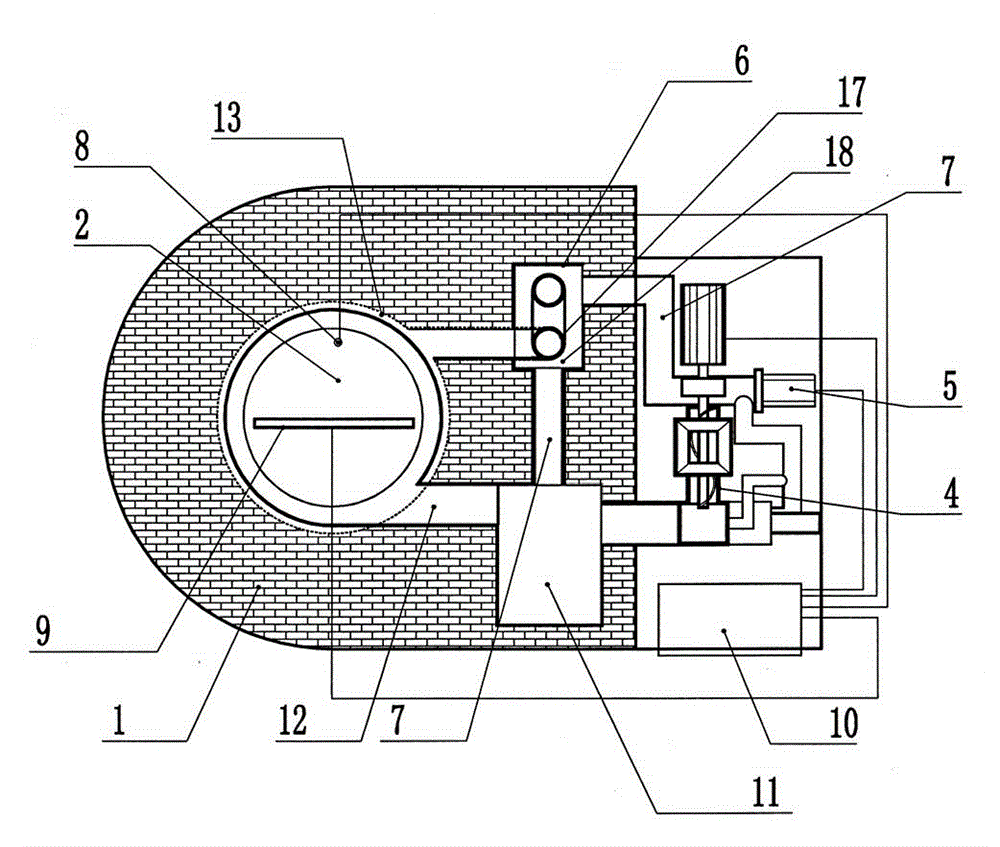

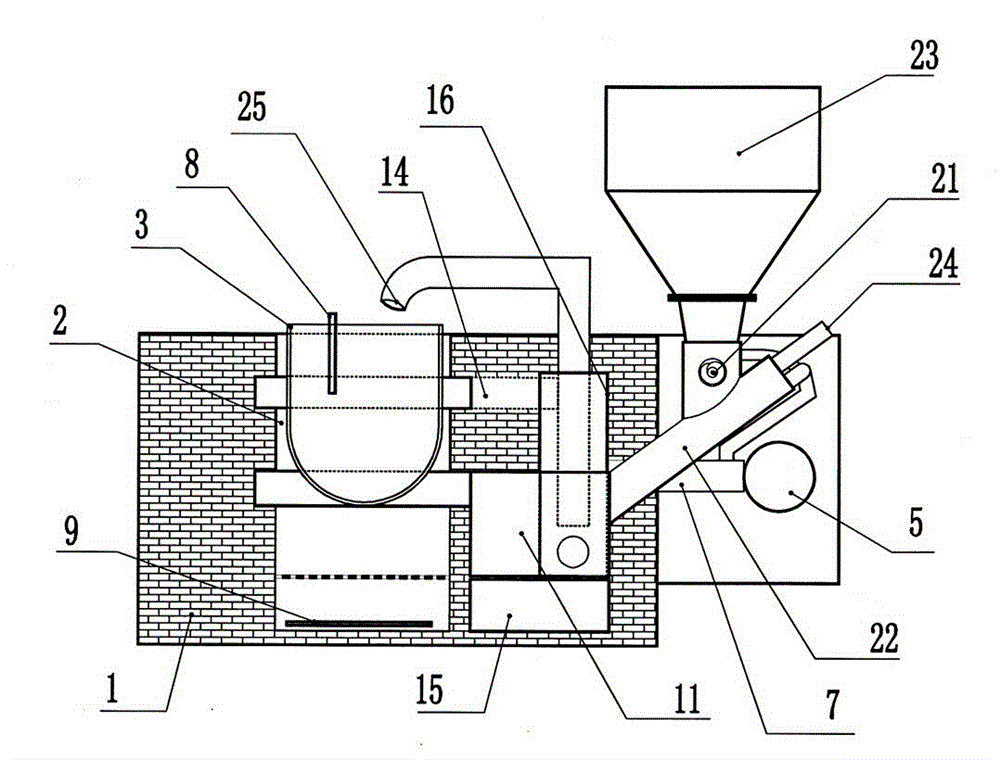

[0015] Such as figure 1 , figure 2 and image 3 As shown, the automatic control high thermal efficiency biological particle fusing furnace includes a furnace body 1, a furnace chamber 2, a fusing pot 3, a fuel delivery device 4, a blower 5, a heat recovery device 6, an air supply pipe 7, a temperature measuring rod 8, a melting The drip sensor 9 and the PLC control system 10 of the boiler are provided with a combustion chamber 11 next to the furnace 2 on the furnace body 1, and a hot air outlet 12 is opened on the combustion chamber 11 to communicate with the furnace 2, and the hot air outlet 12 is arranged tangentially along the furnace 2 A flue 13 is provided around the furnace 2 on the furnace body 1, a flue dredging opening 14 communicating with the flue 13 is provided on the side wall of the furnace body 1, an ash outlet 15 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com