Apparatus and method for natural acceleration test of composite solid propellant

A solid propellant and accelerated test technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of poor consistency of storage performance change results, long cycle, and mechanical property decline, and achieve accurate and reliable test results and simple and easy methods Line, the effect of high acceleration ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

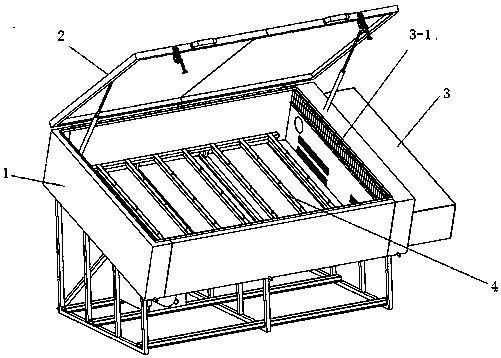

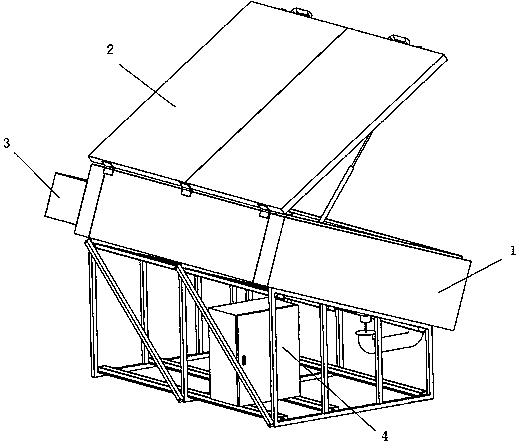

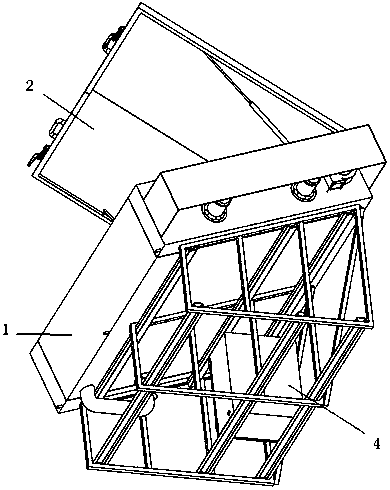

[0024] Embodiment, a kind of compound solid propellant natural acceleration test device, comprises rectangular test box, and test box comprises box body 1 and box cover 2, and box body 1 is a cuboid, external dimension: deep 400mm * wide 1780mm * high 1420mm, net Dimensions: depth 400mm x width 1600mm x height 1300mm. The frame of box 1 is made of SUS304 stainless steel, the outer shell of box 1 is made of 1.5mm thick brushed stainless steel plate, and the inner wall of box 1 is made of 1.0mm thick coated stainless steel plate. A louver 3-1 and a return air hole are arranged on one side wall, and an axial flow fan and a motor are arranged in a cavity outside the louver 3-1. The inner wall of the side wall and the outer shell are filled with high-quality heat insulating material glass wool with a thickness of 100mm as the insulation layer. The bottom of the cabinet 1 is provided with an air inlet, and the inside of the cabinet 1 is 150 mm away from the bottom to make a grid pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com