Three-phase sensorless brushless direct-current motor control system

A brushed DC motor and control system technology, applied in the control system, electronic commutation motor control, current/voltage measurement, etc., can solve the problems of cost increase, volume increase, jitter, etc., and achieve convenient correction, small leakage current, and replacement phase accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Specific embodiments of the present invention will be further described in detail below.

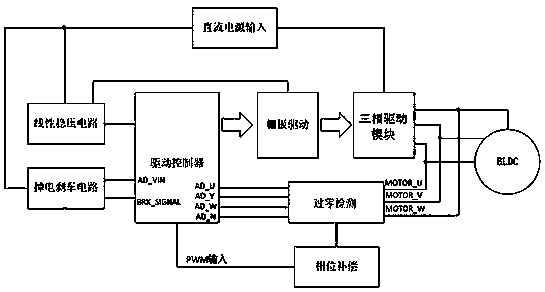

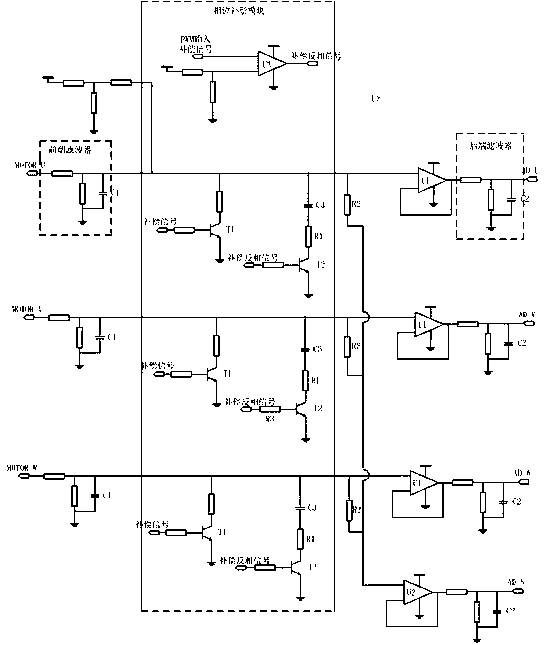

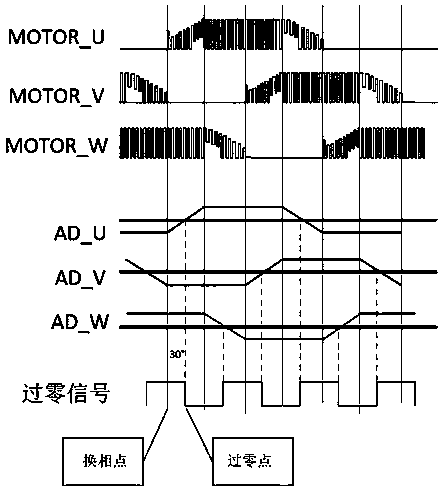

[0039] The three-phase sensorless brushless DC motor control system of the present invention includes a drive controller and a zero-crossing detection circuit. The input terminals of the zero-crossing detection circuit respectively input the three-phase signals output by the motor and convert them into zero-crossing information. The feedback signal of the drive controller outputs the motor control signal according to the feedback signal of the zero-crossing detection circuit, and it is characterized in that it also includes a phase compensation circuit, and the phase compensation circuit outputs a PWM waveform, so that the output feedback signal zero-crossing point is consistent with the set The commutation points of the three-phase signals output by the above-mentioned motors coincide.

[0040] A typical implementation of the control system of the present invention is as follows ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com