Calculation method of vacuum degree in car braking process

A calculation method and braking process technology, applied in the direction of calculation, special data processing applications, instruments, etc., can solve the problem that the braking system is difficult to match reasonably, the braking performance of the vehicle cannot be effectively optimized, and the design selection cannot be effectively provided. Technical support and other issues to achieve the effect of reasonable vehicle braking performance and better performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

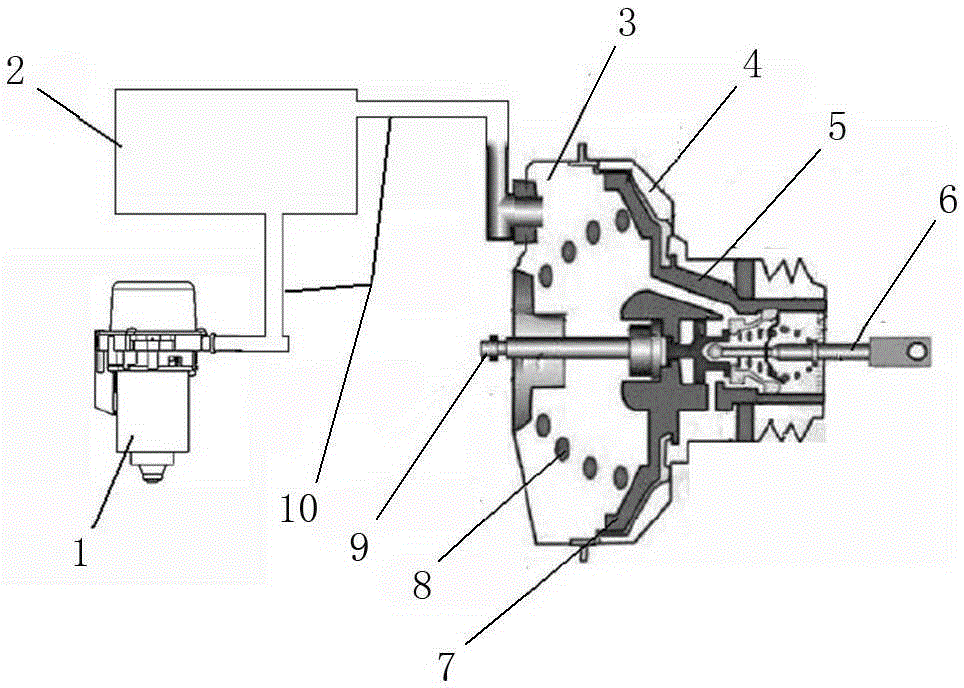

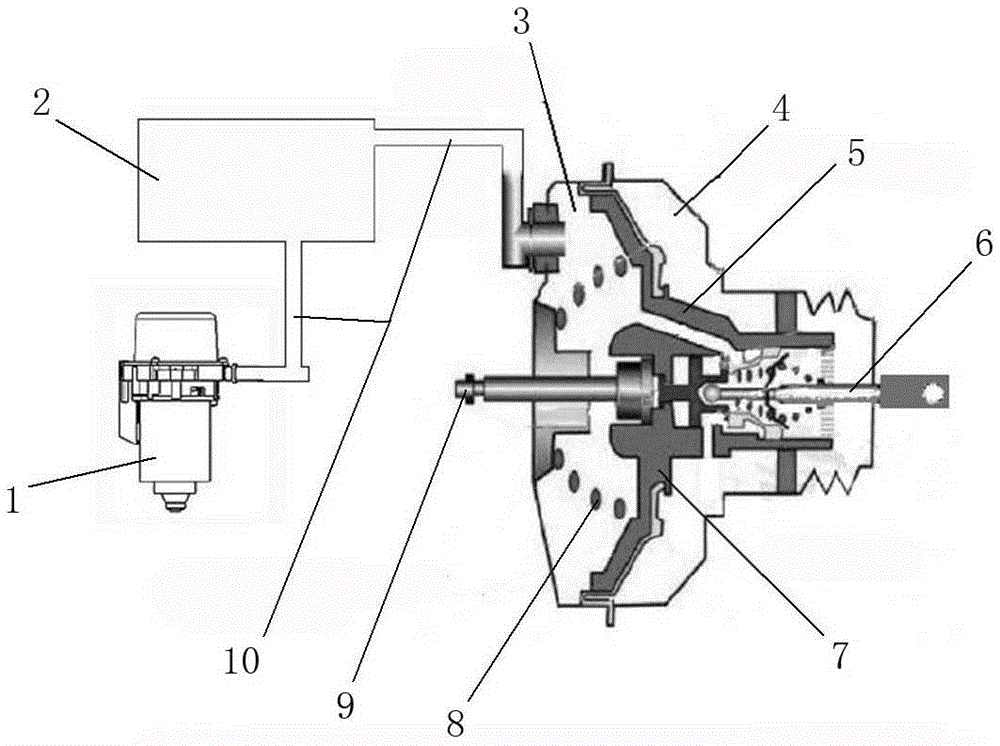

[0035] Example 1: Combining Figure 1-Figure 2 , a calculation method of the degree of vacuum in the braking process of a car, the calculation method is based on the vacuum servo system of the car, and the steps of the calculation method are:

[0036] Step 1: Determine the various parameters of the vacuum servo system in two states; the specific method is as follows: Assume that when the vacuum servo system is in a natural state, the volume of the vacuum booster rear chamber is V 1 , the volume of the front cavity of the vacuum booster is V 2 , the volume of the vacuum tank is V 3 ; Assume that when the vacuum booster is in the maximum stroke state, the volume of the vacuum booster rear cavity will increase, set as V 0 , the maximum stroke of the input push rod is s, the effective diameter of the booster diaphragm of the vacuum booster is d, and the vacuum degree of the system that the electronic vacuum pump can provide is p s -101x10 3 , the pressure in the front chamber ...

Embodiment 2

[0061] Example 2, combined with Figure 1-Figure 2 , the principle and calculation of vacuum degree calculation: vacuum degree is the value that the pressure in a certain volume is lower than the local atmospheric pressure, usually a negative value, and the unit is Pascal, Pa; vacuum degree is a new expression form of atmospheric pressure; The vacuum servo system uses two airtight chambers, one is standard atmospheric pressure and the other is atmospheric pressure with a certain degree of vacuum. The two chambers share one chamber wall, and an effect will be produced on the chamber wall due to different pressures. Force, we use this force to provide boost to the braking system, this force can be called vacuum boost.

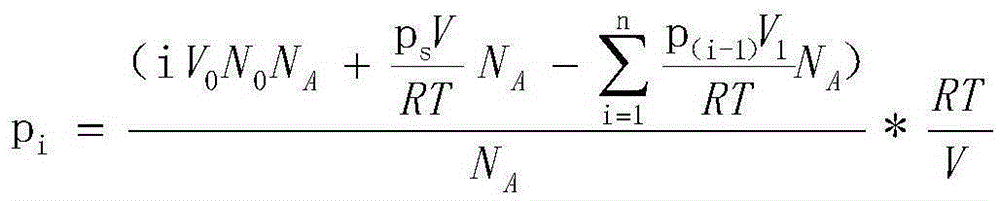

[0062] According to Avogadro's gas pressure formula, the same air temperature and the same air volume, the atmospheric pressure and the number of air molecules have a linear relationship, and we can use this relationship to obtain the vacuum degree of the vacuum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com