Structure and preparation method of nuclear fuel cladding tube with crack expansion resisting capability

A technology for nuclear fuel and cladding tubes, applied in reactor fuel elements, nuclear engineering, nuclear power generation, etc., can solve problems such as hydrogen explosions and nuclear fuel leakage accidents, and achieve the effect of preventing cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

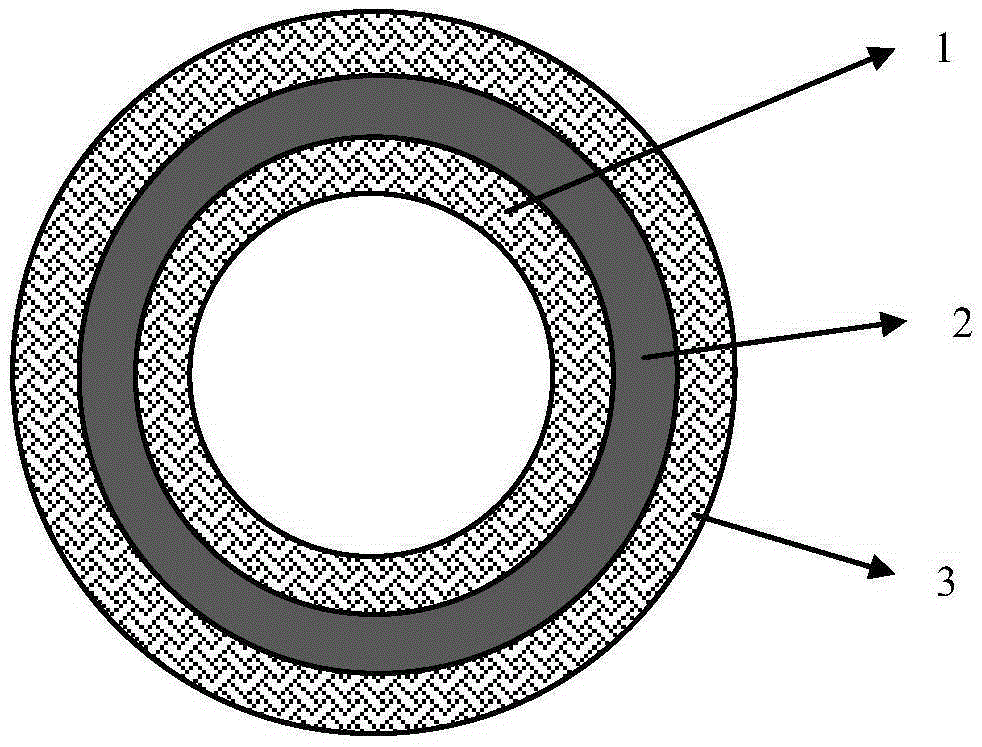

[0033] Example 1: Choose C f Four-layer SiC-based cladding tube with SiC / SiC composite as anti-crack propagation layer. The modulus of elasticity of SiC ceramics is 400-440GPa, while C f The modulus of the / SiC composite material is only 75-85GPa. Therefore it is difficult for the crack to pass through the C f / SiC composite material layer expands radially to the SiC ceramic layer, and the C f Compared with ceramics, the / SiC composite material has better toughness and can prevent the generation and expansion of cracks, thereby better protecting the sub-inner SiC ceramic layer.

[0034] Specific implementation method:

[0035] 1. Preparation of inner layer:

[0036] 1) Using the weaving process, the carbon fiber is made into a tubular fiber prefabricated body with a size of Ф0.9cm×100cm;

[0037] 2) Then deposit a layer of pyrolytic carbon on the carbon fiber preform as a composite material interface layer;

[0038] 3) Using PIP, CVI, RMI or other densification process,...

Embodiment 2

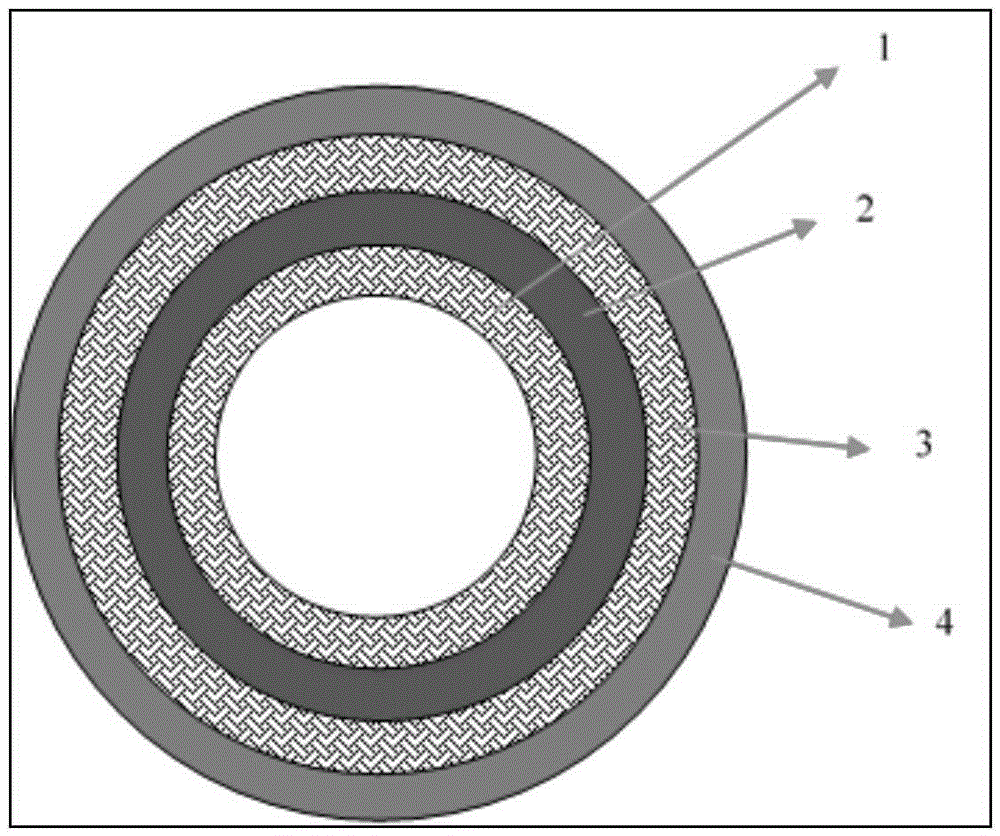

[0045] Example 2: Select SiC f Four-layer SiC-based cladding tube with SiC / SiC composite as anti-crack propagation layer. The modulus of elasticity of SiC ceramics is 400-440GPa, while SiCf The modulus of the / SiC composite material is 150-200GPa. Therefore it is difficult for cracks to pass through SiC f The / SiC composite material layer expands radially to the SiC ceramic layer, and the SiC f Compared with ceramics, the / SiC composite material has better toughness and can prevent the generation and expansion of cracks, thereby better protecting the sub-inner SiC ceramic layer.

[0046] Specific implementation method:

[0047] 1. Preparation of inner layer:

[0048] 1) Using the weaving process, the silicon carbide fiber is made into a round tubular fiber prefabricated body with a size of Ф0.9cm×100cm;

[0049] 2) Depositing a layer of pyrolytic carbon on the silicon carbide fiber prefabricated body as a composite material interface layer;

[0050] 3) Using PIP, CVI, RM...

Embodiment 3

[0057] Example 3: A four-layer SiC-based cladding tube with metal zirconium selected as the anti-crack propagation layer. The elastic modulus of SiC ceramics is 400-440GPa, while the elastic modulus of metal zirconium is 88-100GPa. Therefore, it is difficult for cracks to spread radially through the metal zirconium layer to the SiC ceramic layer, and metal zirconium has better toughness than ceramics, which can prevent the generation and propagation of cracks, thereby better protecting the inner SiC ceramic layer.

[0058] Specific implementation method:

[0059] 1. Preparation of the inner layer: the metal zirconium tube is prepared by CVD process, the size is Ф0.9cm×100cm, and the thickness is 100-500μm;

[0060] 2. Preparation of the second inner layer:

[0061] 1) Clean and dry the surface of the zirconium tube;

[0062] 2) Then brush a layer of SiC precursor on the outer surface, and crack it at 900°C for 1 hour under Ar gas atmosphere to form a layer of SiC ceramic la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com