Environment-friendly and energy-saving equipment with purification device and purification method

A purification device, environmental protection and energy-saving technology, applied in chemical instruments and methods, combined devices, separation methods, etc., can solve the problems of not installing an oil mist separation system purification device, damaging the physical and mental health of staff, and reducing the precision of machine tool processing. Achieve high efficiency and long-lasting filtration efficiency, no obvious change in efficiency, and low maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

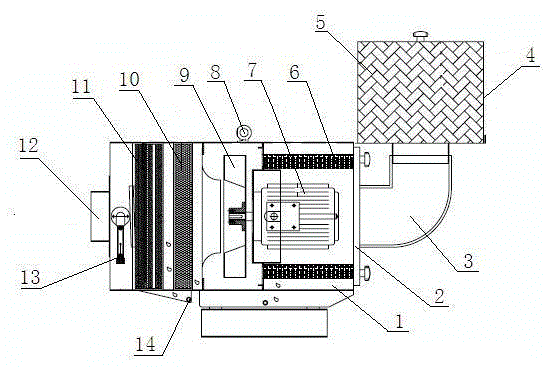

[0024] A kind of environmental protection energy-saving equipment with purifying device, its composition comprises: base base 1, the motor 7 is installed in the groove in the middle part of the base base, a group of three-stage filtering devices 6 are respectively installed on the side of the motor, the The front end of the motor is connected to the centrifugal impeller 9 through a connecting shaft, the front end of the centrifugal impeller is equipped with a secondary filter device 10, the front end of the secondary filter device is equipped with a primary filter device 11, and the front end of the base base is equipped with Oil mist suction port 12.

Embodiment 2

[0026] According to the environmental protection and energy-saving equipment with a purification device described in Embodiment 1, the front end surface of the three-stage filter device is attached to the side surface of the inner groove of the base base, and the rear end surface of the three-stage filter device is in contact with the inner surface of the end cover 2. The end faces are bonded, and the end cover is connected with the bottom plate through bolts.

Embodiment 3

[0028] According to the environmental protection and energy-saving equipment with purification device described in embodiment 2, the end cover has a hole, and a connecting elbow 3 is installed in the hole, and the connecting elbow is connected to the high-efficiency filter 5 through a connecting joint , the side of the high-efficiency filter has a clean air outlet 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com