Acid-system tail gas spraying clear-water-recycling and alkaline-water-draining washing tower and automatic control washing technology thereof

A washing tower and exhaust gas technology, applied in gas treatment, membrane technology, and dispersed particle separation, etc., can solve the problems of unable to reuse the acid regeneration system, waste, and can only be discharged to the waste water station, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

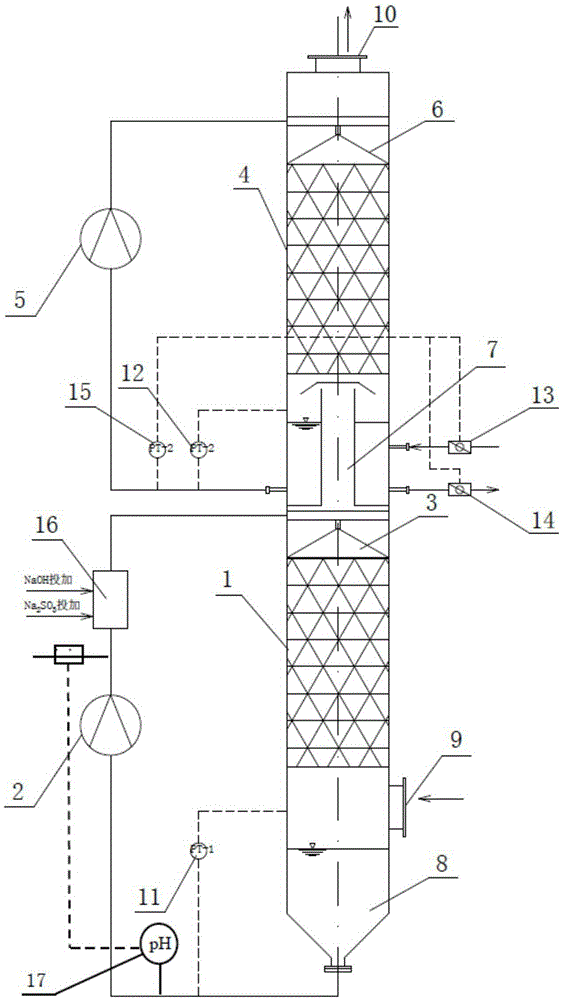

[0027] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0028] refer to figure 1 As shown, the acid system tail gas spray cleaning water reuse and alkaline water discharge washing tower according to the present invention includes a two-layer washing packing area composed of an alkali filling area 1 and a desalinated water filling area 4, and a two-layer washing packing area The liquid storage ventilation tank 7 in the middle and the lye liquid storage area 8, the bottom of the lye liquid storage area 8 is connected with the inlet pipeline of the lye spray circulation pump 2, and the outlet pipeline of the lye spray circulation pump 2 is connected with the pipeline After the mixer 16 is connected, it is connected to the lye nozzle 3 on the upper part of the lye filling area 1. The liquid storage ventilation tank 7 is composed of an intermediate ventilator and a liquid storage tank....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com