Process method for removing fluid inclusions in quartz sand by combining microwaves with acid leaching

A process method combined with acid technology, applied in the field of quartz sand purification, can solve the problems of different technical effects, unclear influence rules, different technical solutions and technical effects, etc.

Inactive Publication Date: 2016-03-23

HUNAN UNIV OF TECH

View PDF1 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] However, the technical effects produced by different microwave powers are different, and in the removal process of quartz sand gas-liquid inclusions, in addition to the influence of microwave power, other key factors such as the type of single acid, acid concentration, and acid leaching time have great influence on the gas-liquid inclusions of quartz sand. The influence law of inclusion removal effect is not clear, so the existing relevant research results in this field provide different technical solutions and technical effects

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0036] The quartz sand material was irradiated with 2400w microwave for 3h, and then pickled with 15% hydrochloric acid for 12h.

Embodiment 2

[0038] The quartz sand material was irradiated with 1800w microwave for 3 hours, and then pickled with 5% hydrochloric acid for 6 hours.

Embodiment 3

[0040] The quartz sand material was irradiated with 2100w microwave for 3h, and then pickled with 10% hydrochloric acid for 24h.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

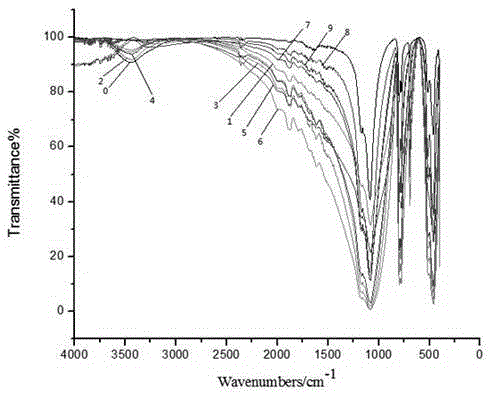

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a process method for removing fluid inclusions in quartz sand by combining microwaves with acid leaching. According to the process method disclosed by the invention, microwave power is the most critical factor which affects the removal effect of the fluid inclusions in quartz sand, and a scientific and accurate treatment process is put forward. The process comprises the steps of: performing irradiation treatment on high-purity quartz sand by microwaves, wherein the microwave power is 1800-2400w; and then performing acid leaching by using monomer acid with a mass fraction of 5-15% for 6-24 hours, wherein the monomer acid is hydrochloric acid, nitric acid or hydrofluoric acid. A plenty of experiments verify that the light transmissivity of quartz sand materials treated by the process is stabilized to be not less than 90.0%, and reaches up to 99.2%, and the purity of SiO2 reaches 99.988%. The process method disclosed by the invention is simple to operate, stable and reliable and suitable for industrial production.

Description

technical field [0001] The invention relates to the technical field of quartz sand purification, more specifically, to a process method for removing gas-liquid inclusions in quartz sand by combining microwave with acid leaching. Background technique [0002] Quartz sand is an important industrial mineral raw material. It has been widely used in traditional industrial production and modern technology. The processed quartz powder is the raw material for manufacturing various materials in the mechanical casting industry and the chemical industry. It has high purity, Quartz with good transparency can also replace crystal to make quartz glass and artificial crystal. The traditional raw materials of high-quality quartz glass are first-class and second-class natural smelted crystals, but the crystal resources are close to exhaustion and cannot meet the needs of modern high-tech industrial development, prompting people to explore alternative quartz glass raw material minerals. my c...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C01B33/12

CPCC01B33/12C01P2002/82

Inventor 刘平乐侯熠徽侯清麟段海婷饶居华颉雨佳米佳黎明侯晶晶

Owner HUNAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com