3,3-gem-difluoro cyclobutanecarboxylic acid industrial preparation method

A technology of difluorocyclobutanecarboxylic acid and difluorocyclobutanecarboxylic acid, applied in the direction of carboxylate preparation, chemical instruments and methods, carboxylate/lactone preparation, etc. Reagents are expensive and other problems, to achieve the effect of low cost and reasonable reaction process selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following examples help to understand the present invention, but do not limit the content of the present invention.

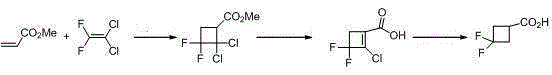

[0016] Synthesis of methyl 2,2-dichloro-3,3-difluorocyclobutanecarboxylate

[0017] Cool 1,1-dichloro-2,2-difluoroethylene (618g, 4.64mol) to -10-0°C, mix well with methyl acrylate (200g, 2.32mol), and add to the autoclave. Heat the reaction to 150° C., and react for 15-20 hours to obtain a reaction liquid containing the product.

[0018] Take 50g of the above reaction solution, adjust the pH value to 5-7 with sodium hydroxide, then concentrate under reduced pressure to 50-100mL, add 100mL of water, concentrate under normal pressure, collect the distillate, extract with dichloromethane (100mL*3), The organic phase was concentrated to obtain 16 g of fine product (yield 65-70%). NMR characterization 1 HNMR (CDCl 3 )9.78(1H,s), 3.23(1H,m), 3.10(1H,m), 2.80(1H,m).

[0019] 2-Chloro-3,3-difluoro-1-enecyclobutanecarboxylic acid

[0020] Prepare an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| NMR spectroscopy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com