Wear-resistant and antistatic PA46 alloy for steel-making workshop high-load wheels, and preparation method thereof

A high-load, load-carrying wheel technology, applied in the field of preparation of wear-resistant and antistatic PA46 alloy, can solve the problems of poor dimensional stability, poor toughness, temperature difference, etc., and achieve the effect of long service life and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Mix PPS, dried PA46, PA66, treated anti-wear agent and antistatic agent, compatibilizer, antioxidant and lubricant in the mixer for 3 minutes in proportion to make it fully stirred , mixed evenly; then sent into the twin-screw extruder, at the same time, adding alkali-free glass fiber into the twin-screw extruder, through the twin-screw high-speed shearing, mixing, extruding from the die, drawing, drying, pelletizing , magnetic and packaging.

[0047] Screw temperature: Zone 1 270°C, Zone 2 305°C, Zone 3 295°C, Zone 4 290°C, Zone 5 285°C, Zone 6 280°C, Zone 7 290°C, Zone 8 300°C, Die 310°C.

Embodiment 2

[0049] According to the process conditions in Example 1 and the material ratio in Table 1, a wear-resistant and antistatic PA46 alloy for high-load load wheels in a steelmaking workshop was prepared.

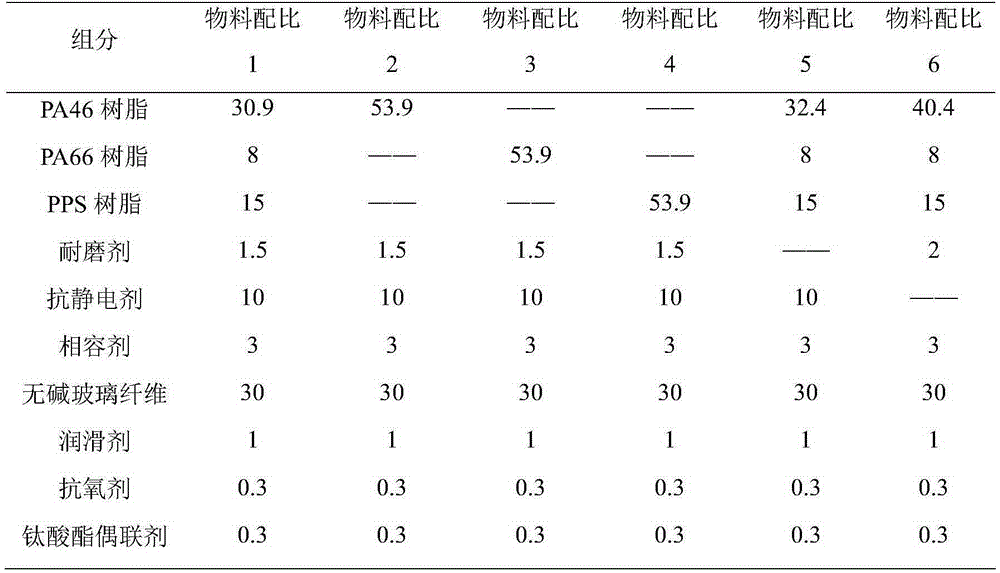

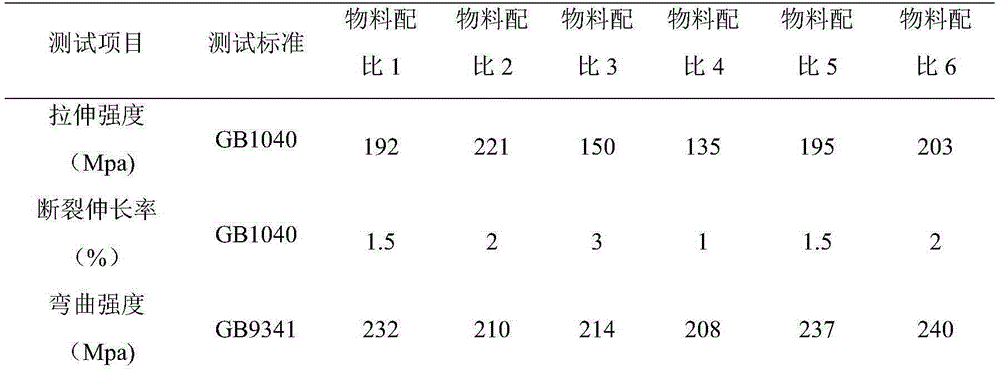

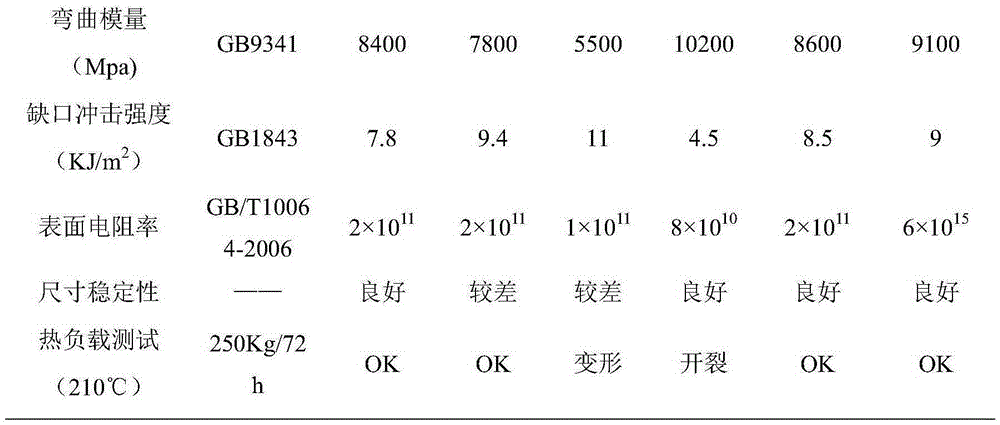

[0050] Table 1 is the percentage by weight of each component

[0051]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com