Multifunctional solid fermenting device

A technology of solid-state fermentation and fermentation equipment, which is applied in the field of multi-functional solid-state fermentation equipment, can solve the problems of many links, wide land occupation, and difficult control of product quality, and achieve the effect of improving quality and occupying a small area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

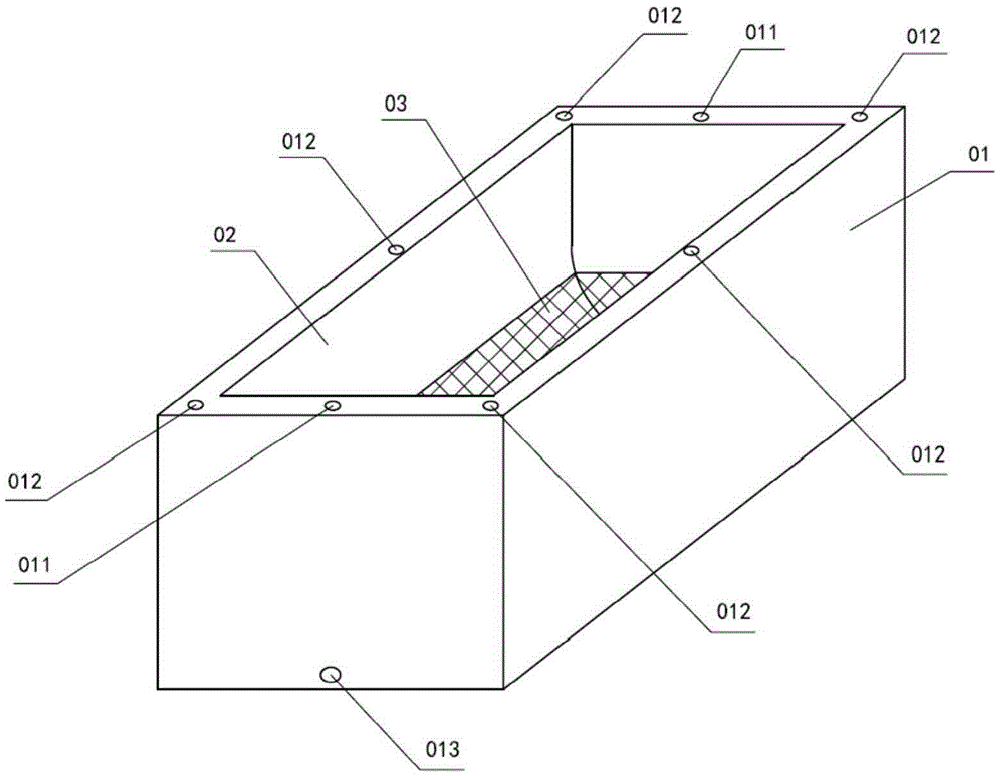

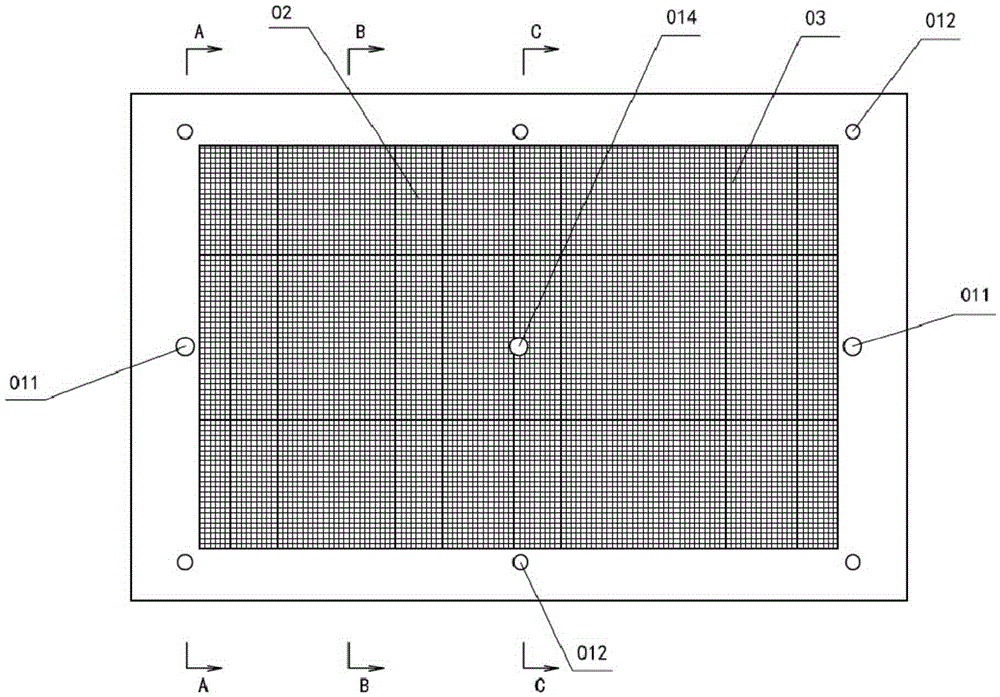

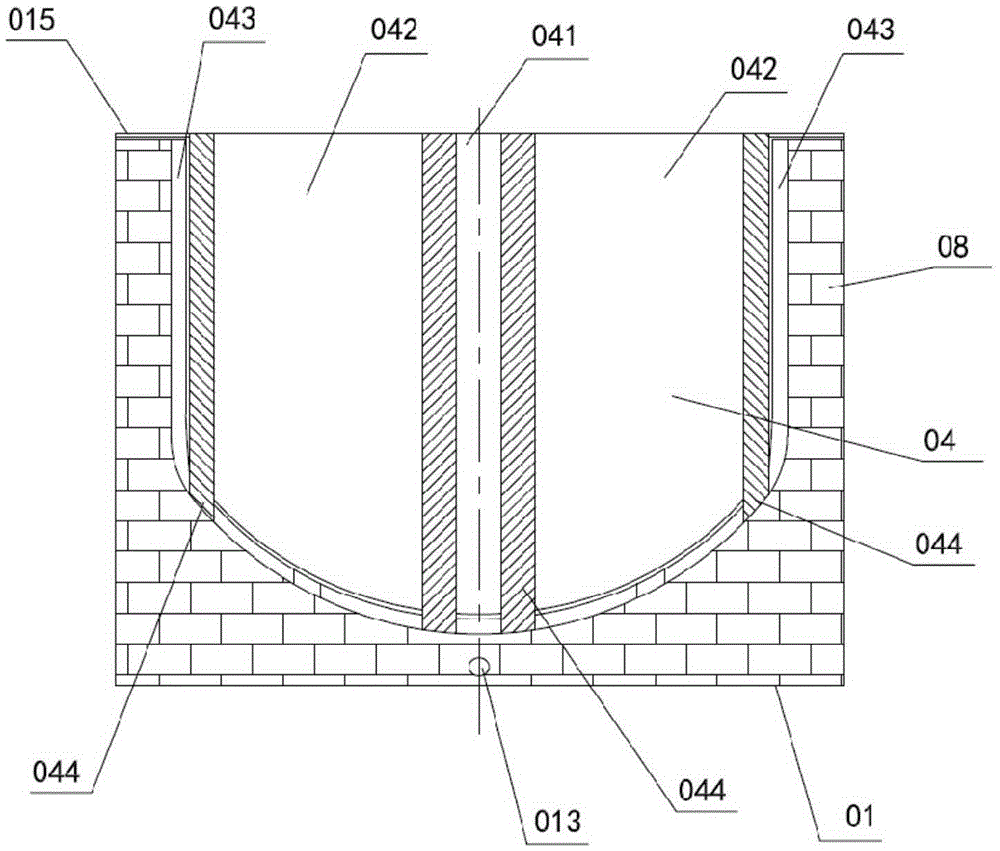

[0035] For the structural diagram of Embodiment 1 of the multifunctional solid-state fermentation device of the present invention, see Figure 1 to Figure 6 , including an inner shell 02 with a fermentation chamber and a fermentation device main body 01 arranged on the periphery of the inner shell 02, the inner shell 02 is inside the fermentation device main body 01, and the upper mouth of the inner shell (02) is rolled back under the anti-skid mat (015) The expansion screw is fixed, and a water bath heat preservation channel is provided between the inner shell 02 and the main body 01 of the fermentation device. Net 03 and the second filter screen 06, the second filter screen 06 is located below the first filter screen 03, the bottom of the inner shell 02 is provided with a liquid outlet hole 014, and the bottom of the main body 01 of the fermentation d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com