Drilling tool for breaking rocks by producing compound action through rotary-percussion mode

A compound action and drilling tool technology, which is applied in earthwork drilling, drilling equipment, driving devices for drilling in boreholes, etc., can solve problems such as unfavorable cementing, well completion, unfavorable borehole quality, and slowdown of drilling speed. It achieves the effects of optimizing wellbore conditions, high rock breaking efficiency and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

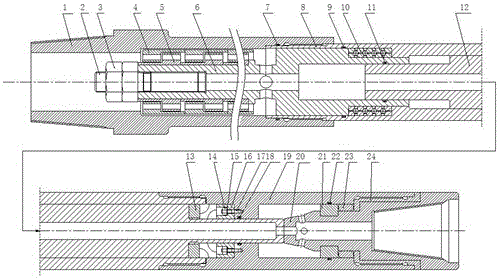

[0021] The present invention will be further described below in conjunction with accompanying drawing:

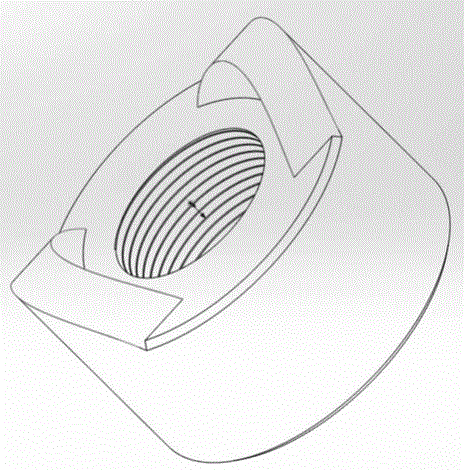

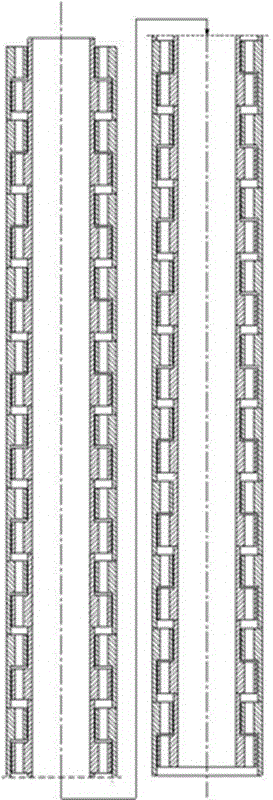

[0022] see figure 1 , A drilling tool that uses the rotary punching method to generate composite rock breaking. The drilling tool is installed on the upper part of the drill bit, and the impact force of the rotary punching method is applied to the drill bit. The new drilling tool includes a power end, an impact shaft assembly and a lower tool assembly. The power end is the upper casing 1, the turbine rotor 4, the turbine stator 5, the upper shaft 6 thrust ball bearing group 10, etc. The turbine rotor 4 and the blades of the turbine stator 5 are installed in reverse, and the stud bolts 2 and hexagonal locks are used to prevent loosening. The nut 3 fixes the turbine stator 5 on the upper shaft 6, connects the upper casing 1 and the middle casing 8 with threads, and installs an O-ring 7 to seal the gap between the upper casing 1 and the middle casing 8. A thrust ball bearing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com