Four-way reversing valve with stopping function

A four-way reversing valve, functional technology, applied in the direction of multi-way valves, valve details, valve devices, etc., can solve the problems of less refrigerant in the evaporator, energy waste, and slow reduction of the air temperature of the indoor unit of the air conditioner, etc. To achieve the effect of rapid cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

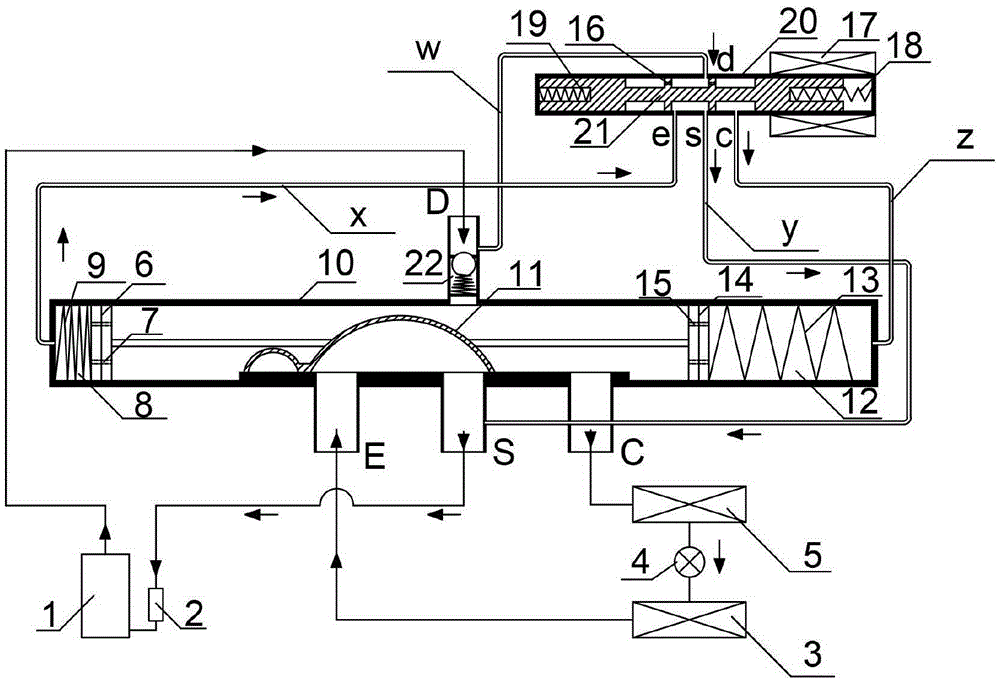

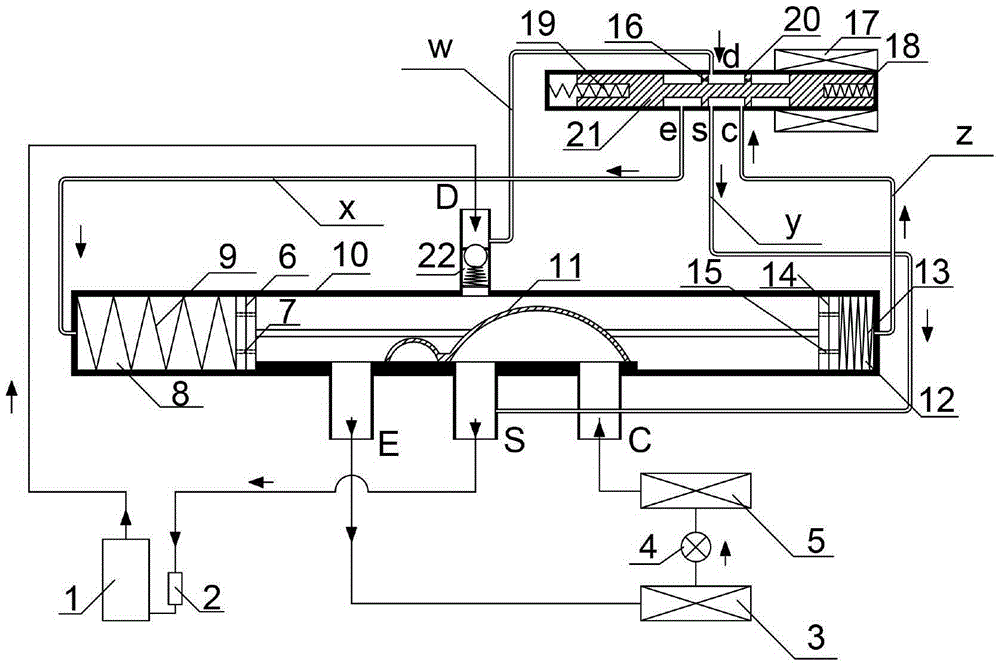

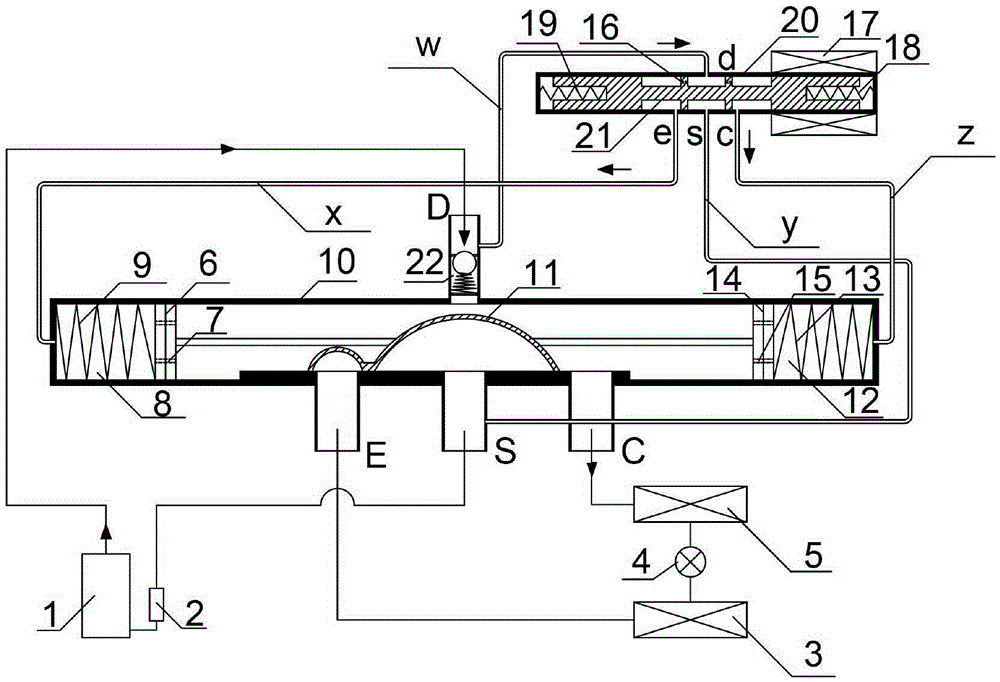

[0027] The concrete structure of the present invention is as figure 1 shown. from figure 1 As can be seen from the figure, a four-way reversing valve with a cut-off function of the present invention is composed of a main valve 10, a pilot valve 20 and capillary tubes (w, x, y, z); the high-pressure inlet nozzle of the main valve 10 D is connected to the exhaust port of compressor 1, the left reversing nozzle E is connected to the outlet of indoor heat exchanger 3, the right reversing nozzle C is connected to the inlet of outdoor heat exchanger 5, and the low-pressure outlet pipe S is connected to the compressor The gas-liquid separator 2 in front of the machine 1 is connected; the main valve 10 has a slider 11, a check valve 22, a piston I14, a piston II6, a spring III13 and a spring IV9, and there are through holes at both ends of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com