Metal strain gauge defect automatic detection system

An automatic detection and strain gage technology, which is applied in the direction of optical testing for flaws/defects, can solve problems such as inconsistent judgment standards, high manual labor intensity, and low detection efficiency, so as to reduce manual labor intensity, avoid missed inspections, and improve efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further elaborated below in conjunction with the accompanying drawings.

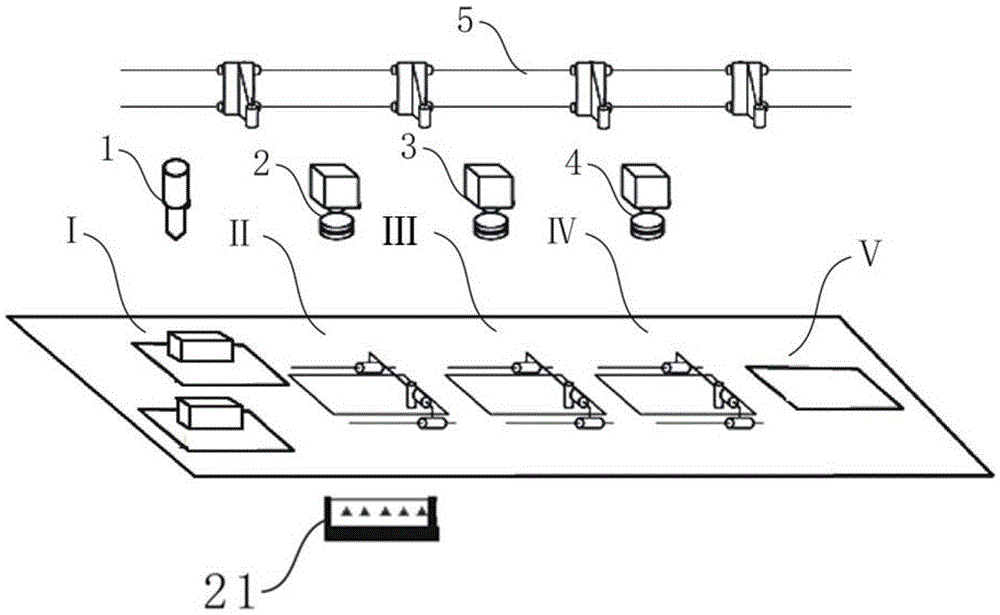

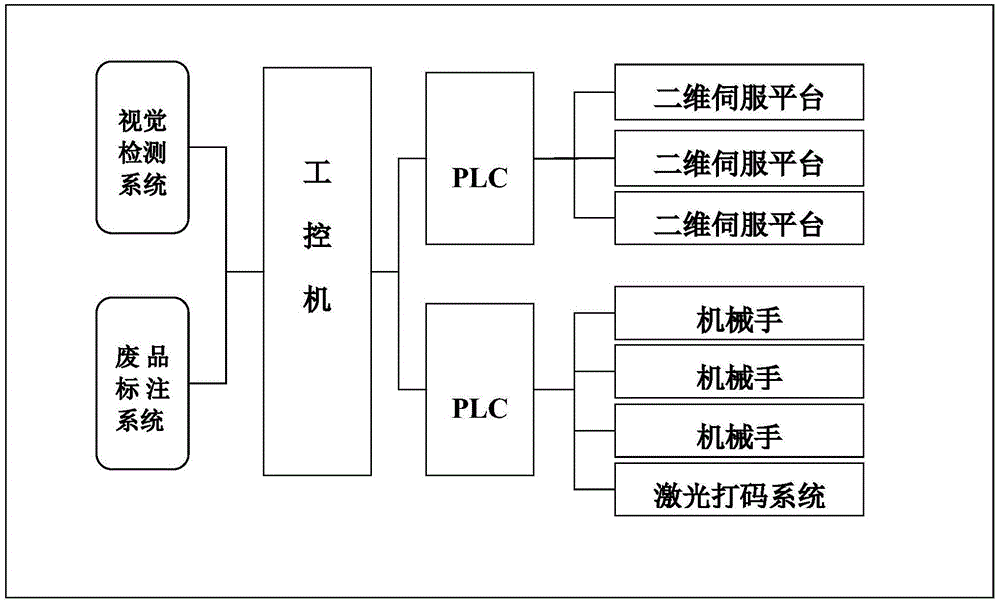

[0020] refer to figure 1 As shown, one embodiment of the present invention is an automatic detection system for metal strain gauge defects, the system includes a feeding leveling mechanism 1, a visual inspection mechanism 2, a laser marking mechanism 3, a waste labeling mechanism 4 and a manipulator assembly 5, the aforementioned The feeding leveling mechanism 1, visual inspection mechanism 2, laser coding mechanism 3 and waste labeling mechanism 4 are respectively installed on the loading station I, visual inspection station II, coding station III and waste labeling below the manipulator assembly 5. Station IV; and the above-mentioned visual inspection mechanism 2, laser marking mechanism 3 and waste product marking mechanism 4 all need to be connected to the control system;

[0021] More specifically, the feeding leveling mechanism 1 includes a station platform on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com