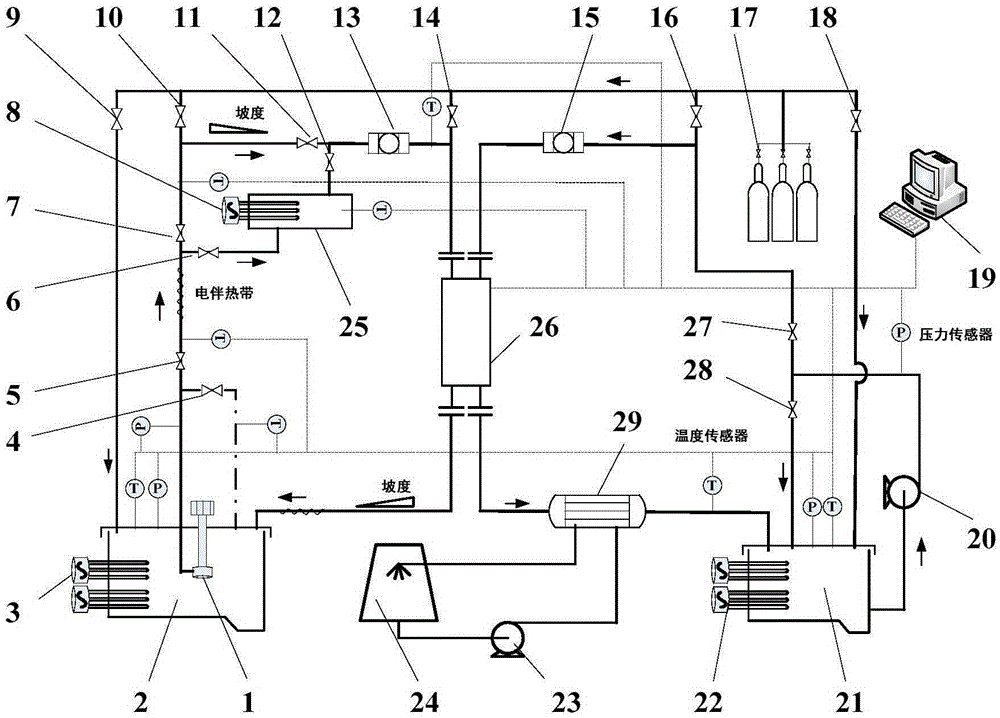

Device for performance testing of molten salt heat exchange/accumulation equipment

A technology of equipment performance and testing device, applied in the field of molten salt working medium heat exchange, can solve the problems of high cost, small flow range, limited types of molten salt heat exchange or heat storage equipment, etc. The effect of temperature regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

[0050] The performance test device for molten salt heat exchange / heat storage equipment provided by the present invention needs to solve the following main difficulties: 1. How to accurately control the flow rate. In a large flow range, it is difficult to accurately adjust only by adjusting the frequency of the pump. Further adjustment of the flow rate through the valve may cause too much pressure fluctuation in the pipeline, which will cause leakage and damage accidents of the experimental pipeline or equipment, and increase the risk of the experiment.

[0051] 2. How to precisely control the heating power. For such a comprehensive experimental platform, the experimental test object is as large as an integral heat exchanger or as small as a single heat exchange tube; Using the power of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com