Monitoring method for electrical endurance of arc-extinguishing chamber of circuit breaker and determination method for initial time of arcing current

A starting time and circuit breaker technology, which is applied in the field of judging the starting time of arcing current and monitoring the electric life of circuit breaker arc extinguishing chamber, can solve the problem of inability to accurately judge the arcing time of fault breaking current and the inability to effectively and accurately determine arcing Start time, difficulty in determining which field probe signal is desired, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

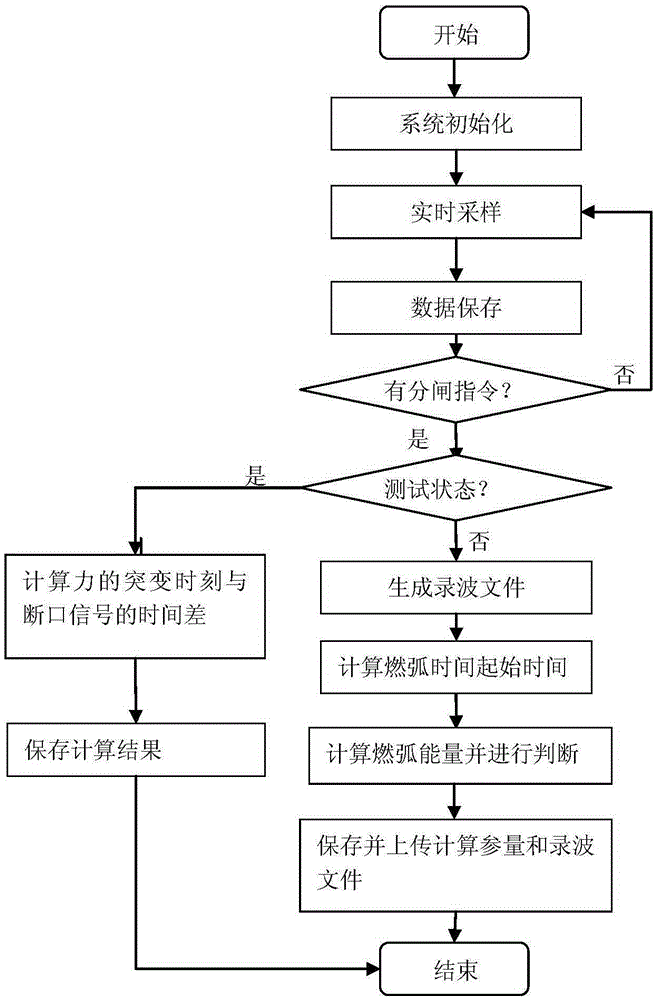

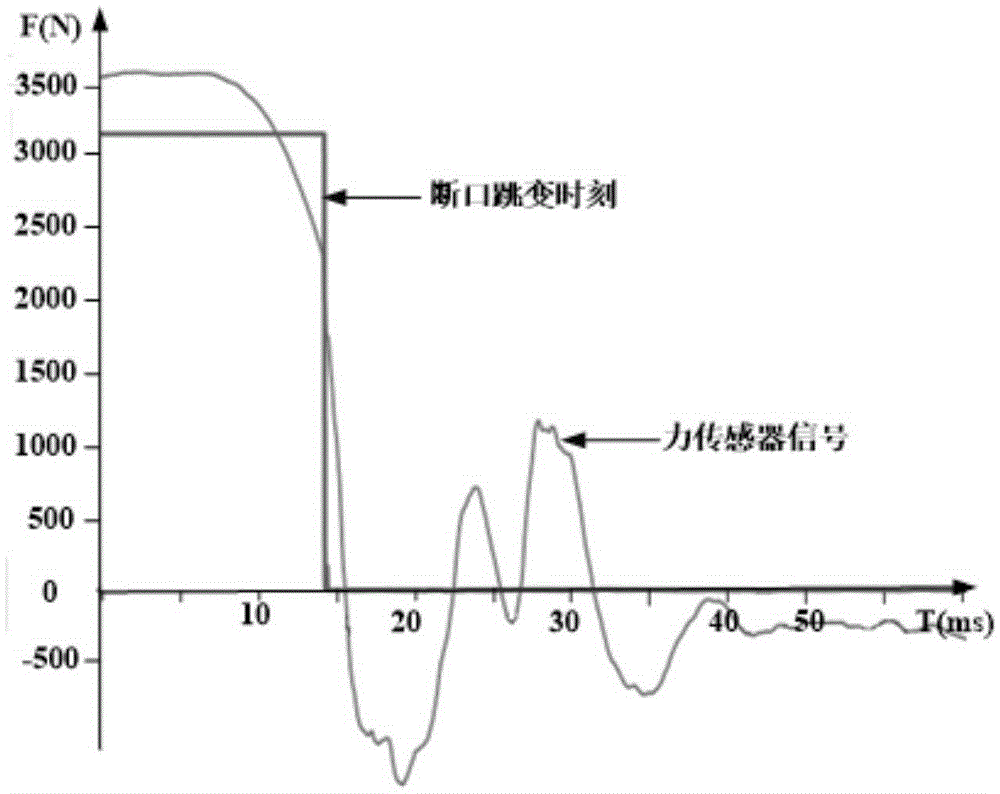

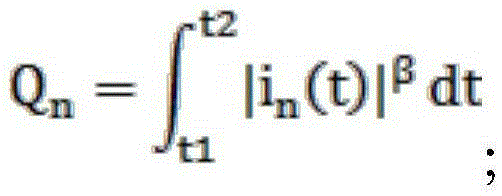

[0036] The purpose of the present invention is to provide a method for accurately determining the starting time of arcing, solve the problem of inaccurate judgment of the starting time of arcing in the switchgear, and realize the wave recording of the arcing current and the calculation of the arc energy of each phase of the running switchgear. And according to the threshold value set by the cumulative arcing energy of each phase, an early warning is given to realize the monitoring of the electrical life of the circuit breaker's arc extinguishing chamber. At the same time, through the collection of raw arc current data, a foundation is laid for accurately determining the correspondence between arc energy and electrical life of contacts.

[0037] The invention can collect the 3-phase protection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com