Figure simulation method for unsteady-state heat transfer process of large-sized crude oil floating-roof tank

A technology of numerical simulation and heat transfer process, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems that it can only be used as a reference, cannot obtain the change law of the temperature field, and is not easy to apply to engineering practice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

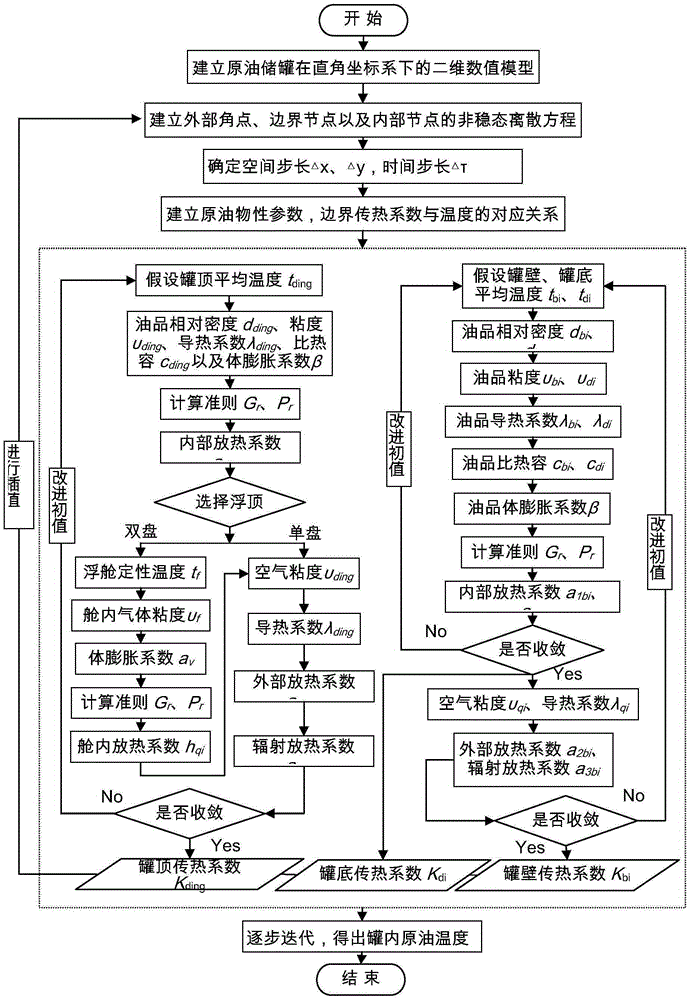

Method used

Image

Examples

Embodiment 1

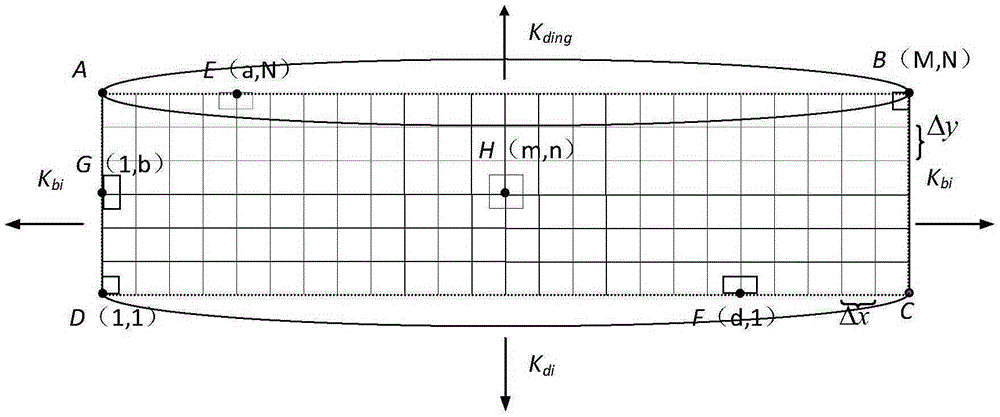

[0132] In order to make the above content of the present invention more obvious and easy to understand, a storage tank in Daqing Oilfield is used as the research object below to simulate the unsteady state heat transfer process of crude oil temperature in the tank, and the details are as follows:

[0133] A 10×104 double-disc floating roof storage tank in an oil depot in Daqing Oilfield has a bottom diameter of 80m, a tank wall height of 21m, and an oil level in the tank of 8.2m. The external ambient temperature is 18°C and the wind speed is 5m / s. The density at 20°C is 980kg / m 3 , the viscosity is 8.4×10-6m 2 / s, the viscosity of the oil at 15°C is 10.53×10-6m 2 / s, the thickness of the tank wall insulation material is 0.08m, and the thermal conductivity is 0.035W / m·℃. The initial temperature of the oil temperature drop in the tank is 42.5℃, and the temperature drop time is 15 days. The simulation process of the crude oil temperature in the tank is as follows:

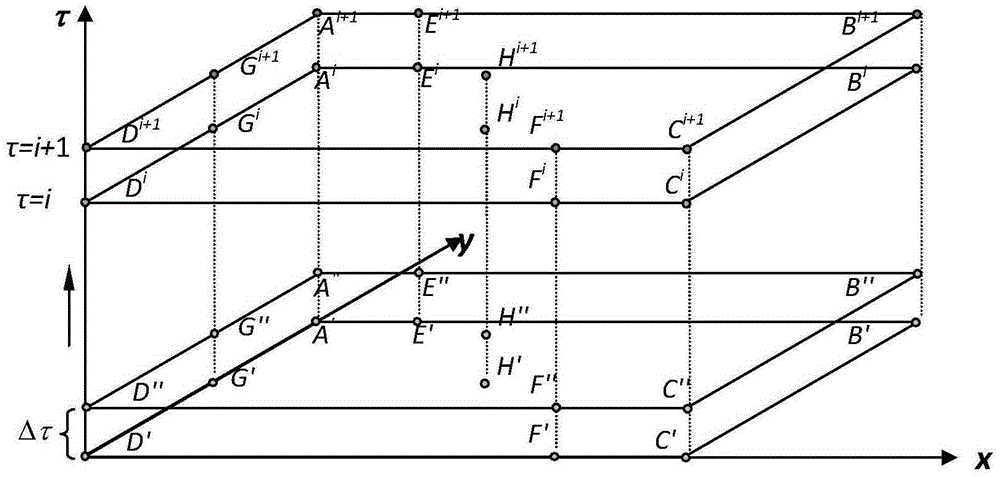

[0134] St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com