Bonding wire

A technology of bonding wire and alloy wire, applied in the field of bonding wire, can solve the problems of low oxidation resistance, low manufacturing cost of silver alloy wire, and high cost of bonding wire, and achieves strong oxidation resistance and stable performance. Good, the effect of solving the migration problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The steps of the preparation method of bonding wire of the present invention are as follows:

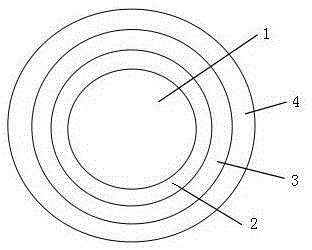

[0021] (1) Vacuum melting of gold, silver and palladium according to the mass ratio (5-20): (60-94): (1-20), drawing and casting into alloy wire rods with a diameter of 10-6mm, through large and medium Pulling and then micro-drawing until the diameter is 40-80μm to obtain the bonding wire matrix;

[0022] (2) Gold plating on the bonding wire substrate, wherein the mass of the gold coating is 1wt%-5wt% of the mass of the bonding wire substrate;

[0023] (3) ultrasonically cleaning the alloy wire in step (2), and plating palladium on the gold coating, wherein the quality of the palladium coating is 1wt%-5wt% of the sum of the bonding wire substrate and the gold coating mass;

[0024] (4) ultrasonically cleaning the alloy wire in step (3), and plating platinum on the palladium coating, wherein the quality of the platinum coating is 4wt%-10wt% of the sum of the mass of the bondin...

Embodiment 1

[0030] (1) Vacuum melting of gold with a purity of 99.999% or more, silver with a purity of 99.99% or more and palladium with a mass ratio of 99.99% or more is 5:94:1, and cast into an alloy wire rod with a diameter of 10~6mm. , middle drawing, and then micro drawing to a diameter of 80 μm to obtain a bonded wire matrix.

[0031] (2) A layer of gold is electroplated on the bonding wire substrate by a cyanide-free electroplating method, the purity of the gold is more than 99.999%, and the mass of the gold plating layer is 1wt% of the mass of the bonding wire substrate.

[0032] (3) Ultrasonic cleaning is carried out on the alloy wire in step (2), and a layer of palladium is electroplated on the gold coating by the method of cyanide-free electroplating. The purity of palladium is more than 99.99%, and the quality of the palladium coating is the bonding wire substrate and the gold coating. 1wt% of the sum of mass.

[0033] (4) Ultrasonic cleaning is performed on the alloy wire i...

Embodiment 2

[0036] (1) Vacuum melting of gold, silver and palladium according to the mass ratio of 20:60:20, drawing and casting into alloy wire rods with a diameter of 10~6mm, through large, medium and then micro drawing to a diameter of 40, to obtain bond Synthetic matrix;

[0037] (2) Gold-plated on the bonding wire substrate, the purity of gold is more than 99.999%, and the quality of the gold coating is 5wt% of the mass of the bonding wire substrate;

[0038] (3) Ultrasonic cleaning is performed on the alloy wire in step (2), and palladium is plated on the gold coating, the purity of palladium is more than 99.99%, and the quality of the palladium coating is 5wt% of the sum of the bonding wire matrix and the gold coating quality;

[0039] (4) Perform ultrasonic cleaning on the alloy wire in step (3), and plate platinum on the palladium coating. The purity of platinum is more than 99.99%, and the quality of the platinum coating is 10wt of the sum of the bonding wire matrix, gold coatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com