Water-cooling device for motor

A water-cooling device and water-cooling technology, applied in the direction of electromechanical devices, cooling/ventilation devices, electrical components, etc., can solve problems such as cracking of welding points, weak welding, motor burnout, etc., and achieve the effect of reducing welding points and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

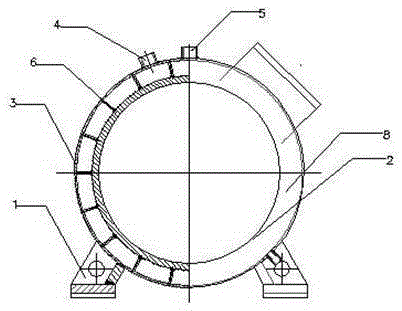

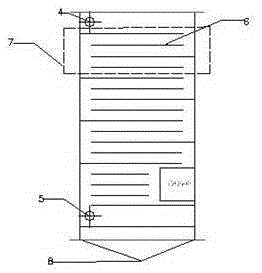

[0019] The reference signs in the drawings of the specification include: base 1 , base inner cylinder 2 , base outer ring 3 , water injection port 4 , water outlet 5 , outer rib 6 , water cooling unit 7 , and sealing plate 8 .

[0020] Example basic reference figure 1 and figure 2 Shown:

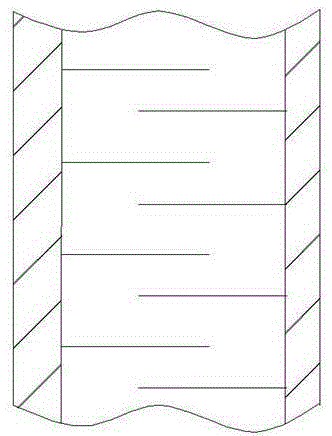

[0021] The motor water cooling device in this solution discloses a motor water cooling device, which includes a base 1 and a sealing plate 8. The base 1 is provided with a base outer ring 3, and the base outer ring 3 is provided with an organic seat inner cylinder. Cylinder 2 is made of hot-rolled seamless steel pipe. The inner cylinder 2 of the base is provided with a groove for interference fit with the outer rib 6. The inner cylinder of the machine base and the outer ring 3 of the base are welded by a sealing plate 8. The outer ring 3 of the base The top is provided with a water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com