Electrical rotating machines

A technology for rotating electrical machines and rotors, applied in the direction of AC motor control, electrical components, electromechanical devices, etc., to achieve the effect of suppressing the decline in energy transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

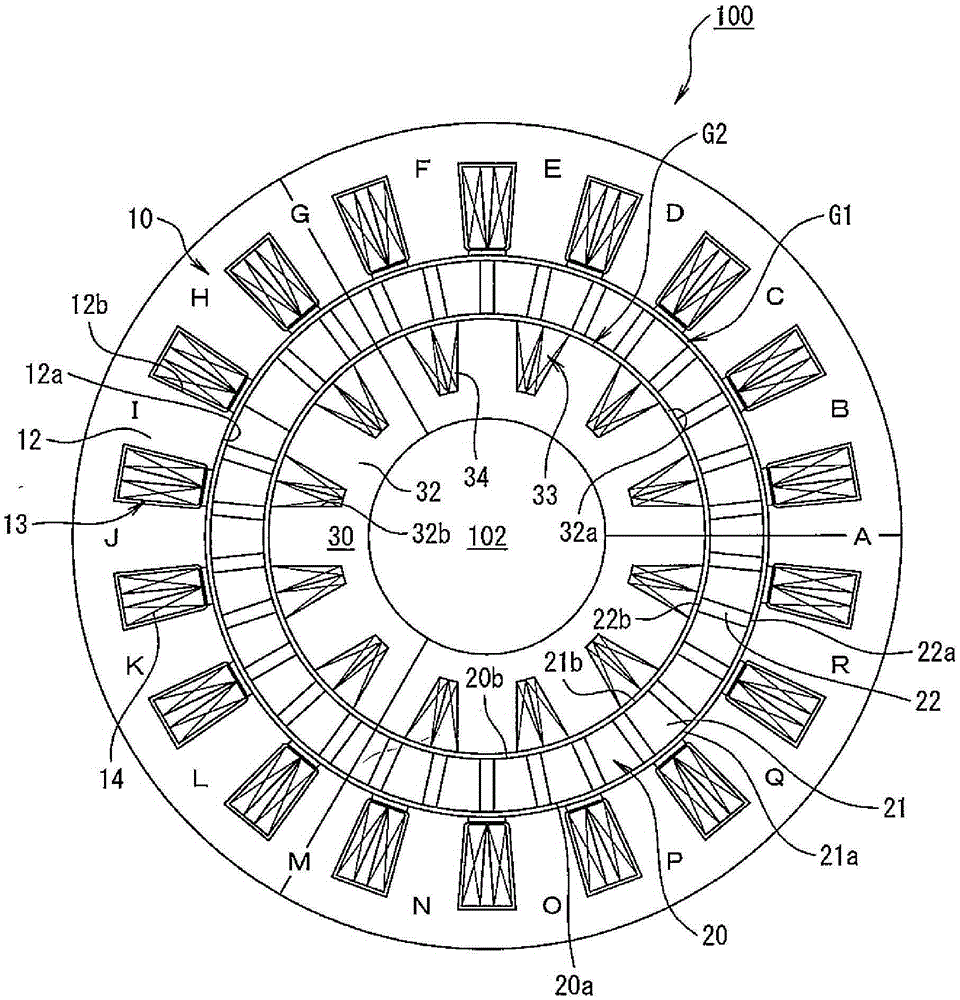

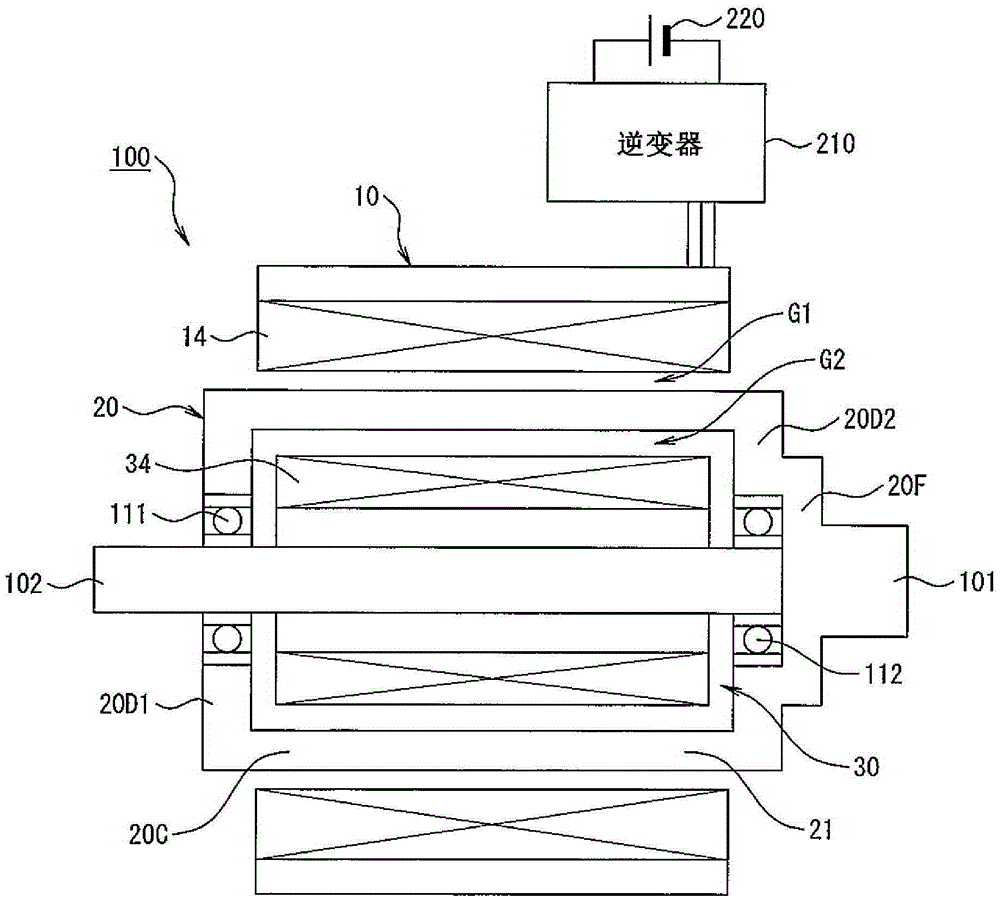

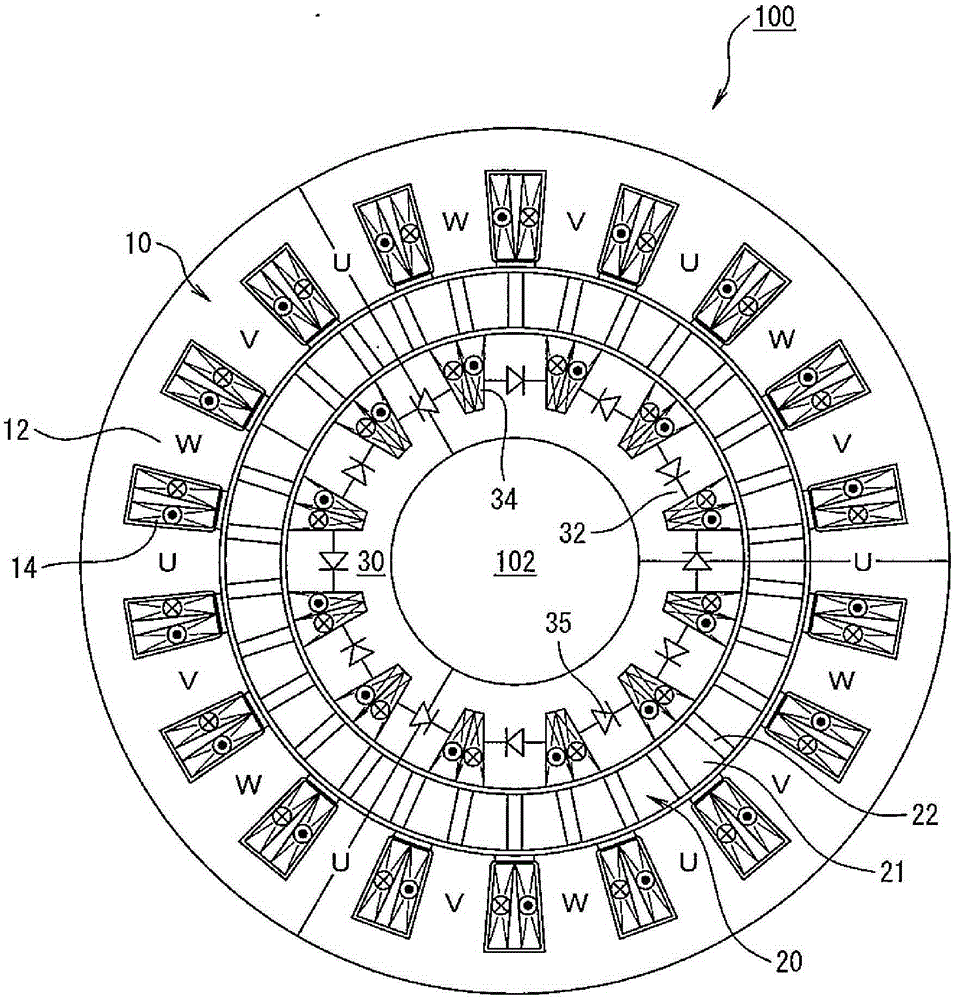

[0056] Embodiments of the present invention will be described in detail below with reference to the drawings. Figure 1 to Figure 12 It is a figure which shows the rotating electric machine which concerns on one Embodiment of this invention.

[0057] exist figure 1 with figure 2 Among them, a rotating electric machine (two-rotor type electric machine) 100 includes: a stator 10 formed in a substantially cylindrical shape; A rotation input shaft (also referred to simply as a rotation shaft) 101; and an inner rotor (first rotor) 30, which is rotatably housed in the outer rotor 20, and a rotation output shaft (also referred to only as axis of rotation) 102 .

[0058] The stator 10 is formed with a plurality of stator teeth 12 extending from the radially outer side toward the radially inner side so that the inner peripheral surface 12 a side faces the outer peripheral surface 20 a of the outer rotor 20 across the air gap G1 . The stator tooth 12 is provided with an armature c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com