Preparation method of rare earth doped indium sulfide nanosheet film photoanode and product thereof

A rare earth doping, photoanode technology, applied in chemical instruments and methods, electrodes, electrolysis processes, etc., to achieve high energy transfer efficiency, inhibit recombination, and improve photoelectrochemical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This example prepares β-In 2 S 3 :Yb 3+ -Tm 3+ Thin film photoelectrode material, In 3+ :Yb 3+ :Tm 3+ =197:2:1

[0026] The raw materials used are shown in Table 1:

[0027] Table 1

[0028]

[0029]

[0030] Preparation:

[0031] 1) First, clean the FTO glass, place the FTO glass in deionized water, ethanol, and acetone for 30 minutes of ultrasonic treatment and blow dry for later use.

[0032] 2) Weigh indium chloride, thioacetamide, ytterbium nitrate, thulium nitrate, and 40ml of deionized water, transfer to a beaker and stir for 30 minutes, in which indium chloride, thioacetamide, ytterbium nitrate, and thulium nitrate Quantities are 0.9456mmol, 2.88mmol, 0.0096mmol, 0.0048mmol, guaranteed In 3+ :Yb 3+ :Tm 3+ =197:2:1, S 2- The amount of the substance is 3 times the sum of the amount of all cationic substances, the concentration of indium chloride, ytterbium nitrate, and thulium nitrate is 24mM, and the concentration of thioacetamide is 72mM.

[...

Embodiment 2

[0035] This example prepares β-In 2 S 3 :Yb 3+ -Tm 3+ Thin film photoelectrode material, In 3+ :Yb 3+ :Tm 3+=193:6:1

[0036] The raw materials used are shown in Table 2;

[0037] Table 2

[0038]

[0039] Preparation:

[0040] 1) First, clean the FTO glass, place the FTO glass in deionized water, ethanol, and acetone for 30 minutes of ultrasonic treatment and blow dry for later use.

[0041] 2) Weigh indium chloride, thioacetamide, ytterbium nitrate, thulium nitrate, and 40ml of deionized water, transfer to a beaker and stir for 30 minutes, in which indium chloride, thioacetamide, ytterbium nitrate, and thulium nitrate Quantities are 0.9264mmol, 2.88mmol, 0.0288mmol, 0.0048mmol, guaranteed In 3+ :Yb 3+ :Tm 3+ =193:6:1, S 2- The amount of the substance is 3 times the sum of the amount of all cationic substances, the concentration of indium chloride, ytterbium nitrate, and thulium nitrate is 24mM, and the concentration of thioacetamide is 72mM.

[0042] Transfe...

Embodiment 3

[0044] This example prepares β-In 2 S 3 :Yb 3+ -Tm 3+ Thin film photoelectrode material, In 3+ :Yb 3+ :Tm 3+ =189:10:1

[0045] The raw materials used are shown in Table 3;

[0046] table 3

[0047]

[0048] Preparation:

[0049] With embodiment 1, difference is, preparation raw material indium chloride (InCl 3 4H 2 O), ytterbium nitrate (Yb(NO 3 ) 3 ·6H 2 O), thulium nitrate (Tm(NO 3 ) 3 ·6H 2 O) molar ratio In 3+ :Yb 3+ :Tm 3+ =189:10:1. Wherein indium chloride, thioacetamide, ytterbium nitrate, and thulium nitrate are respectively 0.9072mmol, 2.88mmol, 0.048mmol, and 0.0048mmol;

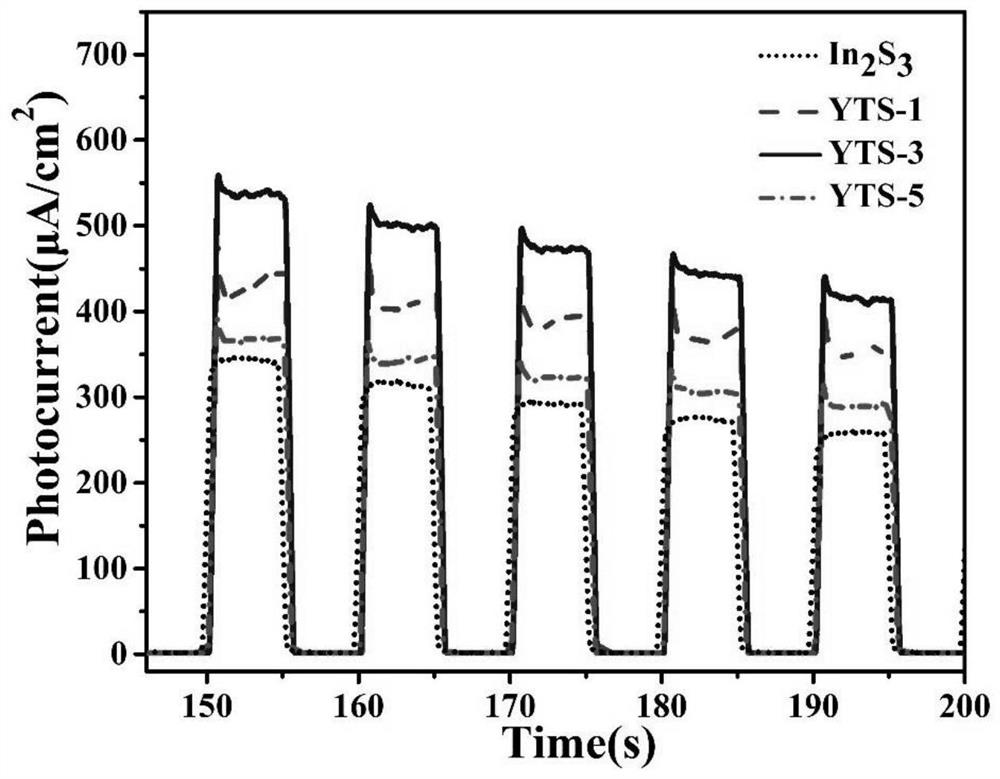

[0050] The prepared film (YTS-5) was taken out from the reactor, rinsed and dried with deionized water. The photocurrent density of the prepared thin film (YTS-5) reached 0.28mA / cm 2 , with pure β-In 2 S 3 Compared with the photoelectrochemical performance, it has a significant improvement, which is about pure β-In 2 S 3 (0.25mA / cm 2 ) 1.14 times ( figure 1 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Photocurrent density | aaaaa | aaaaa |

| Photocurrent density | aaaaa | aaaaa |

| Photocurrent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com