Huoxiang Zhengqi capsule and preparation method thereof

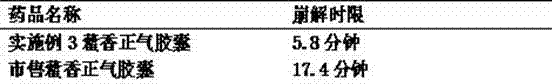

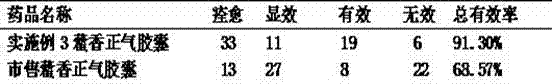

A patchouli, internal injury technology, applied in capsule delivery, pharmaceutical formulations, medical preparations containing active ingredients, etc., can solve the problems of slow disintegration, unsatisfactory curative effect, and low curative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Take 146g of coix seed, 73g of Gorgon fruit, 36.5g of goose herb, 195g of patchouli, 73g of perilla leaf, 73g of Angelica dahurica, 146g of Atractylodes macrocephala (fried), 146g of tangerine peel, 130g of French pinellia, 130g of Magnolia officinalis (made from ginger), Poria cocos 60g, bellflower 146g, pulverized into 60 mesh coarse powder, extracted by carbon dioxide supercritical extraction, extraction pressure 20Mpa, extraction temperature 17°C, separator pressure 11Mpa, separator temperature 36°C, separation time 2.2 hours, carbon dioxide flow per hour 25L to obtain the extract; take the extract and dry it under reduced pressure at 61°C to obtain a dry paste; add 150g of mannitol to the dry paste, and use a high-energy nano-impact mill to pulverize it into a mixed dry paste powder with a particle size of 200-300nm; take the mixed dry paste powder , microcrystalline cellulose 45g, cross-linked polyvinylpyrrolidone 45g, cross-linked carmellose sodium 35g, mix well, ...

specific Embodiment 2

[0032] Take 146g of coix seed, 73g of Gorgon fruit, 36.5g of goose herb, 195g of patchouli, 73g of perilla leaf, 73g of Angelica dahurica, 146g of Atractylodes macrocephala (fried), 146g of tangerine peel, 130g of French pinellia, 130g of Magnolia officinalis (made from ginger), Poria cocos 60g, bellflower 146g, pulverized into 60 mesh coarse powder, extracted by carbon dioxide supercritical extraction, extraction pressure 40Mpa, extraction temperature 37°C, separator pressure 20Mpa, separator temperature 59°C, separation time 3.7 hours, carbon dioxide flow per hour 33L to obtain the extract; take the extract and dry it under reduced pressure at 79°C to obtain a dry paste; add 200g of mannitol to the dry paste, and use a high-energy nano-impact mill to pulverize it into a mixed dry paste powder with a particle size of 200-300nm; take the mixed dry paste powder , microcrystalline cellulose 55g, crospovidone 55g, croscarmellose sodium 45g, mix well, wet granulate with 70% ethanol...

Embodiment 3

[0034] Take 146g of coix seed, 73g of Gorgon fruit, 36.5g of goose herb, 195g of patchouli, 73g of perilla leaf, 73g of Angelica dahurica, 146g of Atractylodes macrocephala (stir-fried), 146g of orange peel, 130g of French pinellia, 130g of Magnolia officinalis (made from ginger), Poria cocos 60g, Platycodon grandiflorum 146g, crushed into 60 mesh coarse powder, extracted by carbon dioxide supercritical extraction, extraction pressure 30Mpa, extraction temperature 27°C, separator pressure 16Mpa, separator temperature 48°C, separation time 3 hours, carbon dioxide flow per hour 29L to obtain the extract; take the extract and dry it under reduced pressure at 70°C to obtain a dry paste; add 175g of mannitol to the dry paste, and use a high-energy nano-impact mill to pulverize it into a mixed dry paste powder with a particle size of 200-300nm; take the mixed dry paste powder , microcrystalline cellulose 50g, crospovidone 50g, croscarmellose sodium 40g, mix well, wet granulate with 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com