A new type of outer wheel cover felt material for passenger cars and its preparation method

A technology for outer wheel cover and passenger car, which is applied in chemical instruments and methods, vehicle components, lamination and other directions, can solve the problems of short wheel cover life, wheel cover damage, tire interference damage, etc., and achieve long wheel cover life and sound absorption. The effect of good performance and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

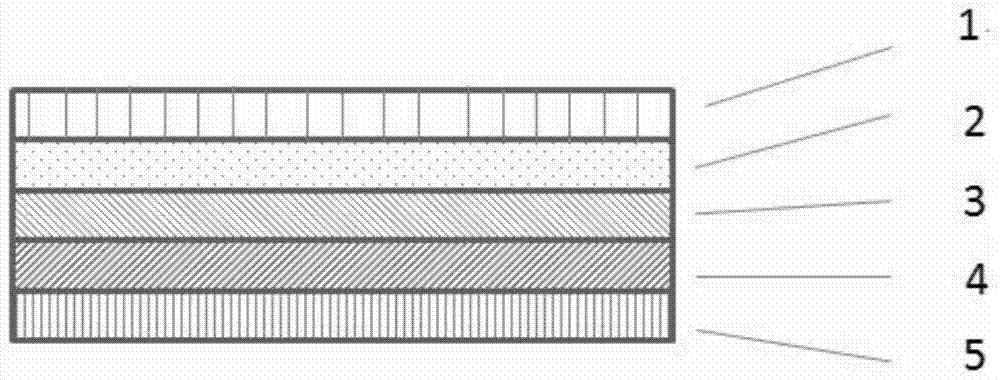

[0032] Three carding machines respectively control the laying of the three-layer structure of the sound-absorbing layer 3, the cushioning and shock-absorbing layer 4, and the rigid support and impact-resistant layer 5. specific:

[0033] 1. Carding and needle punching into felt

[0034] 1. Put polyester fiber and modified polypropylene fiber into the first carding machine. After carding, a rigid support impact-resistant layer is formed, and the rigid support impact-resistant layer fiber web is evenly spread on the conveyor network by cross-laying. on the curtain;

[0035] 2. Put low-melting-point modified polyester fibers and high-elastic polyester fibers with a melting point of 185°C into the second carding machine. After carding, the cushioning and shock-absorbing layer 4 is formed. The laying method is evenly laid on the fiber net of the rigid support impact-resistant layer; the low-melting point modified polyester fiber is a skin-core composite structure, the skin layer ...

Embodiment 2

[0046] Three carding machines respectively control the laying of the three-layer structure of the sound-absorbing layer 3, the cushioning and shock-absorbing layer 4, and the rigid support and impact-resistant layer 5. specific:

[0047] 1. Carding and needle punching into felt

[0048] 1. Put polyester fiber and modified polypropylene fiber into the first carding machine. After carding, a rigid support impact-resistant layer is formed, and the rigid support impact-resistant layer fiber web is evenly spread on the conveyor network by cross-laying. on the curtain;

[0049] 2. Put low-melting-point modified polyester fibers and high-elastic polyester fibers with a melting point of 165°C into the second carding machine. After carding, the buffer and shock-absorbing layer 4 is formed, and the fiber web of the buffer and shock-absorbing layer 4 is passed through the cross The way of laying the net is evenly laid on the fiber net of the rigid support impact-resistant layer;

[00...

Embodiment 3

[0060] Three carding machines respectively control the laying of the three-layer structure of the sound-absorbing layer 3, the cushioning and shock-absorbing layer 4, and the rigid support and impact-resistant layer 5. specific:

[0061] 1. Carding and needle punching into felt

[0062] 1. Put polyester fiber and modified polypropylene fiber into the first carding machine. After carding, a rigid support impact-resistant layer is formed, and the rigid support impact-resistant layer fiber web is evenly spread on the conveyor network by cross-laying. on the curtain;

[0063] 2. Put low-melting-point modified polyester fibers and high-elastic polyester fibers with a melting point of 165°C into the second carding machine. After carding, the buffer and shock-absorbing layer 4 is formed, and the fiber web of the buffer and shock-absorbing layer 4 is passed through the cross The way of laying the net is evenly laid on the fiber net of the rigid support impact-resistant layer;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com