Novel electric truck chassis structure

A truck chassis and electric technology, applied in the substructure, electric power unit, power unit, etc., can solve problems such as limited space, poor protection performance of power batteries, short circuit, etc., achieve high energy efficiency utilization, sufficient expansion installation, and reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

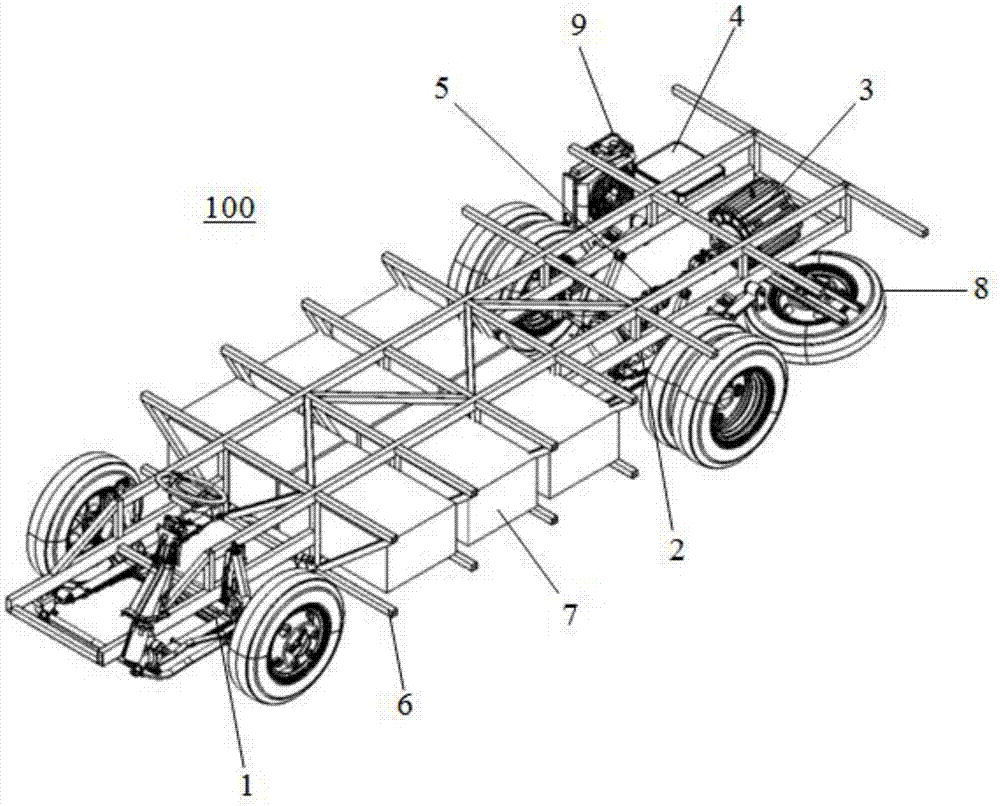

[0030] Please refer to figure 1 , the present embodiment is a novel electric truck chassis structure 100, which includes a front axle 1, a rear axle 2, a motor 3 for driving the rear axle, a motor controller 4, a speed reduction mechanism 5 with one end connected to the rear axle 2 and the other end connected to the motor 3, The truss-type vehicle frame 6 mounted on the front axle 1 and the rear axle 2 and the power battery 7 accommodated inside the vehicle frame 6 are fixed.

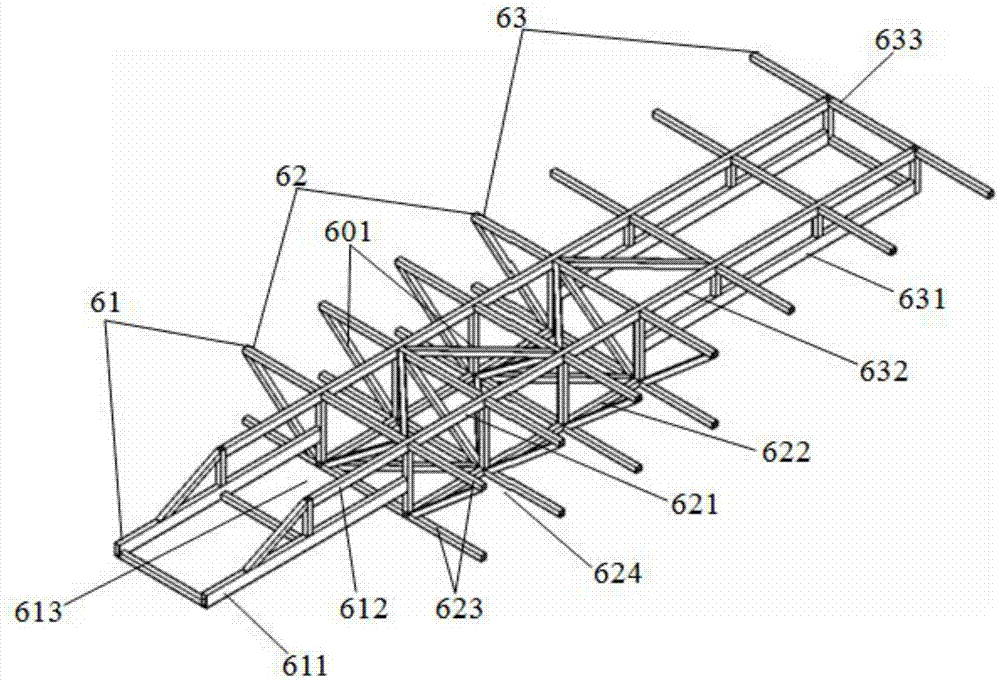

[0031] Please refer to figure 2 , the vehicle frame 6 is a mixed structure of truss and rigid frame, which is mainly formed and welded by rectangular profiles, channel profiles and angle steels.

[0032] The front frame 61 includes two first lower beams 611 fixedly erected on the front axle 1 and arranged in parallel, a first upper beam 612 positioned directly above the first lower beams 611, a first lower beam 611, a first upper beam 612 The first receiving space 613 formed by the middle frame 62 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com