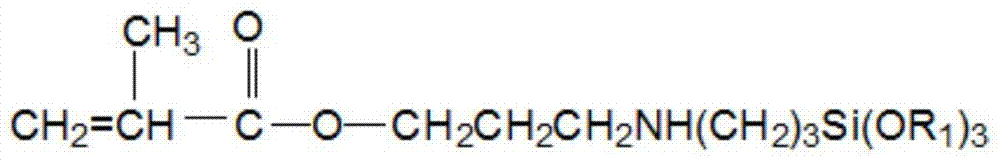

Aminosilyl acrylate and preparation method thereof

A technology of acryloxyaminosilane and aminosilane, which is applied in the field of acryloxyaminosilane and its preparation, can solve the problems of high cost, insufficient strength increase, low use efficiency and the like, and achieves low cost, low roughness, high resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

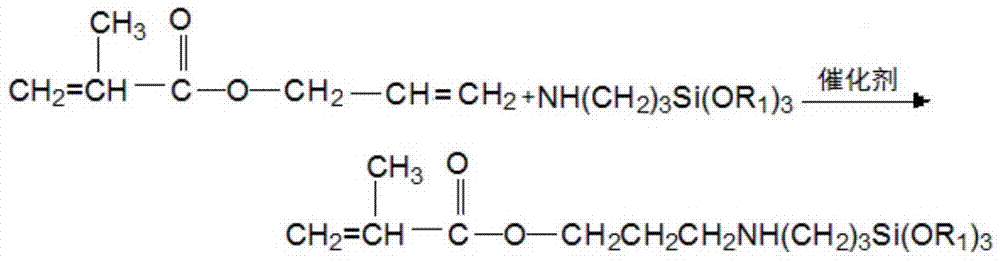

[0046] (1) Add aminosilane and allyl methacrylate in the reactor, the aminosilane here uses aminopropylmethyldiethoxysilane, and the molecular formula is as follows:

[0047]

[0048] The amount of both substances is 1mol; 30% toluene of the total mass is added to the reactor;

[0049] (2) adding benzyltriethylammonium chloride as a catalyst, the quality is 1% of the total mass;

[0050] (3) Heating and stirring in the reactor, the heating temperature is 50° C., and the stirring time is 3 hours, to obtain the desired acryloyloxyaminosilane.

Embodiment 2

[0052] (1) Add aminosilane and allyl methacrylate to the reactor, and the aminosilane here uses aminoethylaminopropyl trimethoxysilane; the amount of both substances is 2mol; add 40% DMF of the total mass;

[0053] (2) adding tetrabutylammonium bromide as a catalyst, the quality is 3% of the total mass;

[0054](3) Heating and stirring in the reactor, the heating temperature is 100° C., and the stirring time is 6 hours, to obtain the desired acryloyloxyaminosilane.

Embodiment 3

[0056] (1) Add aminosilane and allyl methacrylate in the reactor, the aminosilane here uses aminoethylaminopropyl triethoxysilane; The amount of both substances is 2mol; Add 35% benzene of total mass;

[0057] (2) adding tetrabutylammonium bromide as a catalyst, the quality is 2% of the total mass;

[0058] (3) Heating and stirring in the reactor, the heating temperature is 75° C., and the stirring time is 4 hours, to obtain the desired acryloyloxyaminosilane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com