Gate chamber of horizontal gate of high water head ship lock and operation control method of horizontal gate

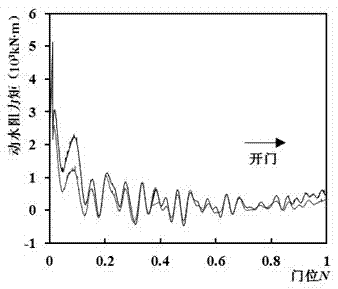

A high water head and door storage technology, applied in ship locks, ship lifting devices, water conservancy projects, etc., can solve the problems of increased vortex strength, increased resistance to dynamic water, and large vortex strength, so as to reduce the swell height to the door. The effect of reducing the dynamic water resistance torque and reducing the opening and closing force of the gate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

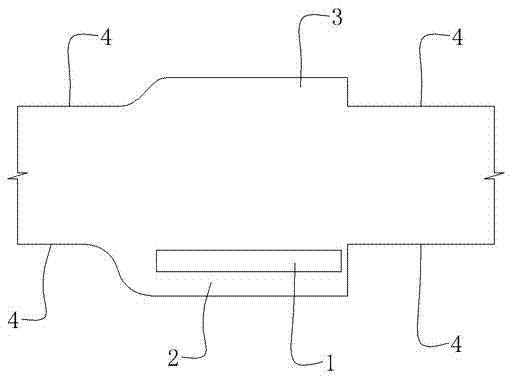

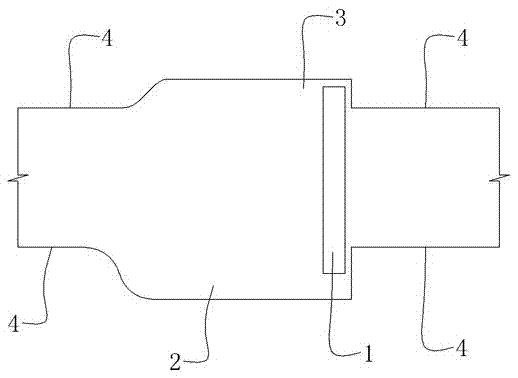

[0031] The door warehouse of the one-word gate of the high-head ship lock of this embodiment, such as Figure 1 to Figure 4 As shown, the door body 1 is used to install the upper gate of the ship lock. The gate house includes the gate wall 4 arranged at the upstream and downstream of the gate body 1. The gate house also includes the first two sides of the lock head opposite to the gate body 1. One door library 2 and second door library 3.

[0032] The first door store 2 and the second door store 3 are respectively formed by the gate walls protruding to both sides. The first door store 2 and the second door store 3 are semi-open door stores connected to the upstream water area. Storage 2 is used to accommodate the door when door 1 is fully opened, and second door 3 is used to support the door head of the door when door 1 is closed to block water. The width of first door 2 and second door 3 is the same as The ratio of the thickness of the door 1 is 1.9~2.2: 1.2:1, the ratio of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com