Self-testing and self-calibrating system of infrared thermopile temperature sensor

A technology of temperature sensor and thermopile, which is used in electrical radiation detectors, radiation pyrometry, instruments, etc., can solve the problems of high calibration costs, difficult testing circuits, and high testing costs, and achieve the effect of saving testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below with reference to the accompanying drawings and in conjunction with its working principle.

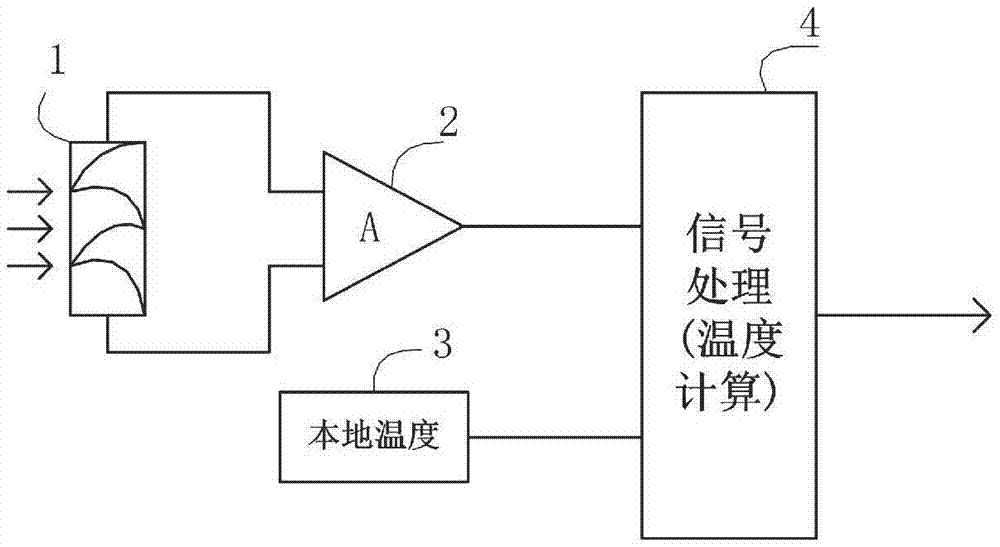

[0032] figure 1 It is a typical structure diagram of an infrared thermopile temperature sensor. It mainly includes thermopile 1, amplifier 2, local temperature measurement circuit 3 and temperature calculation circuit 4, etc. The working principle is: according to Stephen-Boltzmann's law (the radiation power on the surface of a black body is proportional to the fourth power of the thermodynamic temperature of the black body itself, and also proportional to the surface area of the black body) and the Seebeck effect (closed loop is caused by escape The two materials are composed of two conductor materials with different work, the two materials produce a voltage difference due to the temperature difference), the thermopile 1 converts the infrared radiation sensing the object to be measured into a voltage difference signal △...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com