Refrigeration and supercharging system for pipeline structure environmental simulation

A technology of environmental simulation and pressurization system, which is applied to the testing of machines/structural components, measuring devices, instruments, etc., and can solve problems such as pipeline damage and pipeline system vibration faults

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

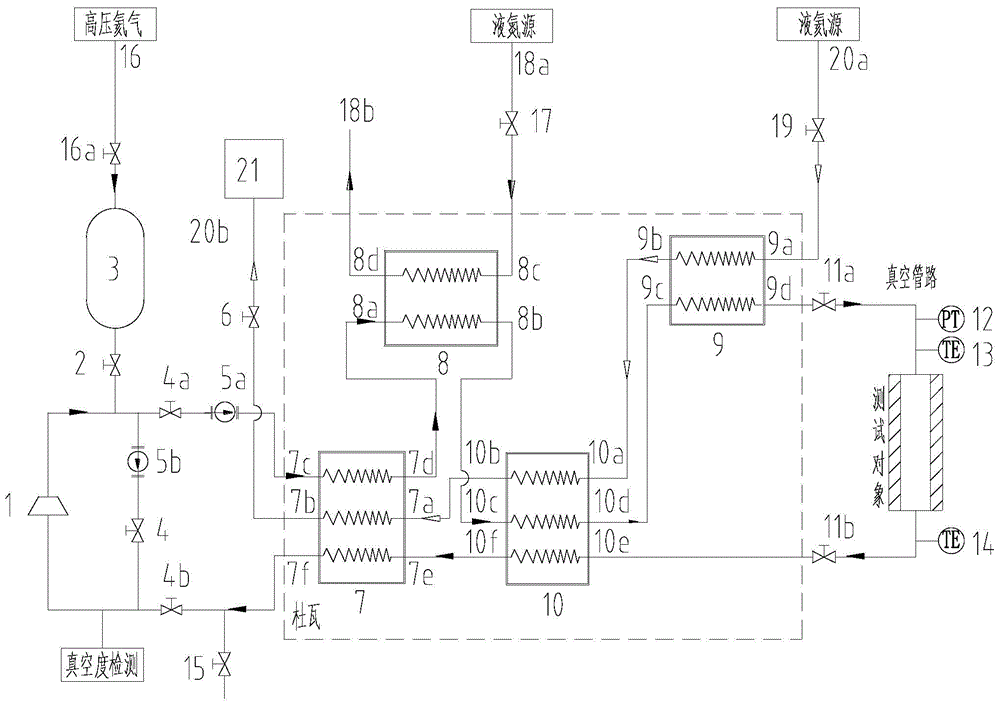

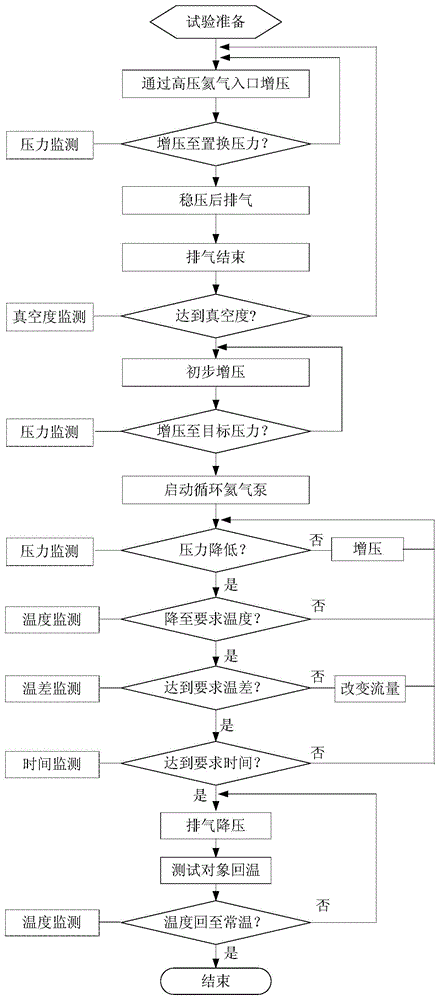

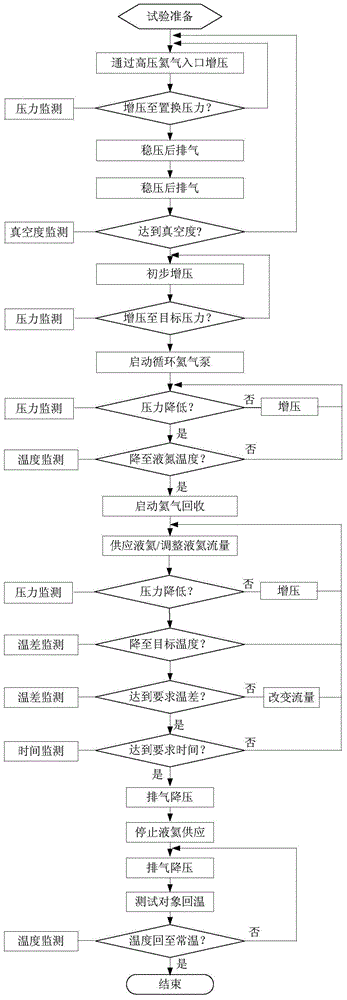

[0029] Such as figure 1 As shown, a refrigeration and pressurization system used for the simulation of pipeline structure environment uses circulating helium to cool and pressurize the test piece, which can realize the low temperature zone above the liquid nitrogen temperature and the liquid helium temperature below the liquid nitrogen temperature zone. The deep low temperature zone above the low temperature zone, and realize the precise adjustment of pressure.

[0030]Including helium circulation pump 1; buffer tank stop valve 2; buffer tank 3; bypass valve 4; normal temperature inlet valve 4a; normal temperature return valve 4b; main flowmeter 5a; bypass flowmeter 5b; helium exhaust Valve 6; primary recuperator heat exchanger 7; primary recuperator heat exchanger liquid helium inlet 7a; primary recuperator heat exchanger liquid helium outlet 7b; prim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com