Construction method of photoelectrochemical aptasensor based on gold/zinc oxide composite material and detection method for bisphenol A

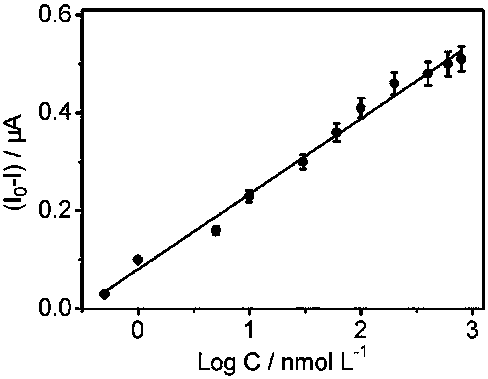

An aptamer sensor and composite material technology, applied in the direction of material electrochemical variables, scientific instruments, analytical materials, etc., can solve the problems of low sensitivity, general selectivity, low light utilization rate, etc., to achieve improved sensitivity and easy transition , high efficiency and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Construction of photoelectrochemical aptasensor based on gold / zinc oxide composite material,

[0030] First, the ITO conductive glass was cut into 1 cm×4 cm, cleaned and rinsed with a mixed solution of ammonia, hydrogen peroxide and deionized water at a volume ratio of 1:1:50, and then dried naturally at room temperature for use.

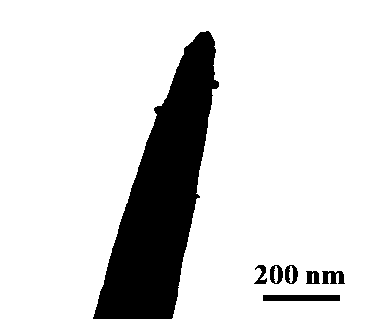

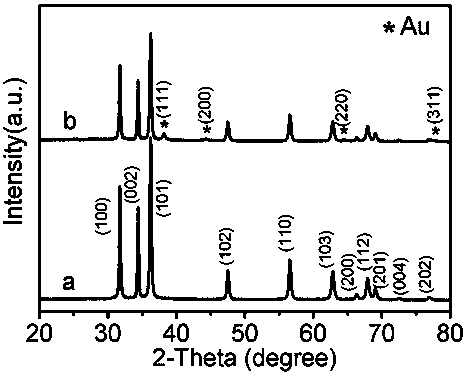

[0031] Then, 10 mL of Zn(NO 3 ) 2 ∙6H 2 O solution (0.5 M) was added dropwise to 10 mL of 4 M KOH solution under magnetic stirring, then the mixed solution was transferred to a 100 mL borosilicate glass bottle and reacted at 30°C for 12 h, the precipitate was collected by centrifugation, and the The mixture was alternately washed with absolute ethanol and pure water three times, and the washed precipitate was dried at 70°C to obtain pure zinc oxide substance.

[0032] Then, the appropriate amount of HAuCl 4 ∙4H 2 O (0.01 gmL -1 ) solution, in which the mass ratio of Au:ZnO was 7 wt% and 1mL methanol solution was added to 20 mL of pure...

Embodiment 2

[0038] The basic steps are the same as in Example 1, the difference is that an appropriate amount of HAuCl 4 ∙4H 2 O (0.01 gmL -1 ) solution, in which Au: ZnO was added to 20 mL of pure water according to a certain mass ratio and 1 mL of methanol solution, and 30 mg of the prepared zinc oxide was weighed and added to the mixture, stirred slowly for 1 h, and then the mixture was transferred to React in a 50 mL autoclave at 120°C for 1 h, cool naturally to room temperature, and finally collect the precipitate by centrifugation, wash the precipitate with absolute ethanol and deionized water alternately for 3 times, and the washed precipitate is at 70°C C conditions, and finally made gold / zinc oxide composite. The mass ratio of Au:ZnO in this step is 1wt%.

Embodiment 3

[0040] The basic steps are the same as in Example 1, the difference is that an appropriate amount of HAuCl 4 ∙4H 2 O (0.01 gmL -1 ) solution, in which Au: ZnO was added to 20 mL of pure water according to a certain mass ratio and 1 mL of methanol solution, and 30 mg of the prepared zinc oxide was weighed and added to the mixture, stirred slowly for 1 h, and then the mixture was transferred to React in a 50 mL autoclave at 120°C for 1 h, cool naturally to room temperature, and finally collect the precipitate by centrifugation, wash the precipitate with absolute ethanol and deionized water alternately for 3 times, and the washed precipitate is at 70°C C conditions, and finally made gold / zinc oxide composite. The mass ratio of Au:ZnO in this step is 3wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com