Measurement method of graphite concentration in insulating oil during roll EDM texturing

A measurement method and concentration measurement technology, applied in the direction of material electrochemical variables, etc., can solve problems such as high roll surface roughness, different roll surface roughness, and adverse effects on production, so as to improve the hit rate of strip steel surface roughness, improve The quality of roll texturing and the effect of ensuring the texturing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

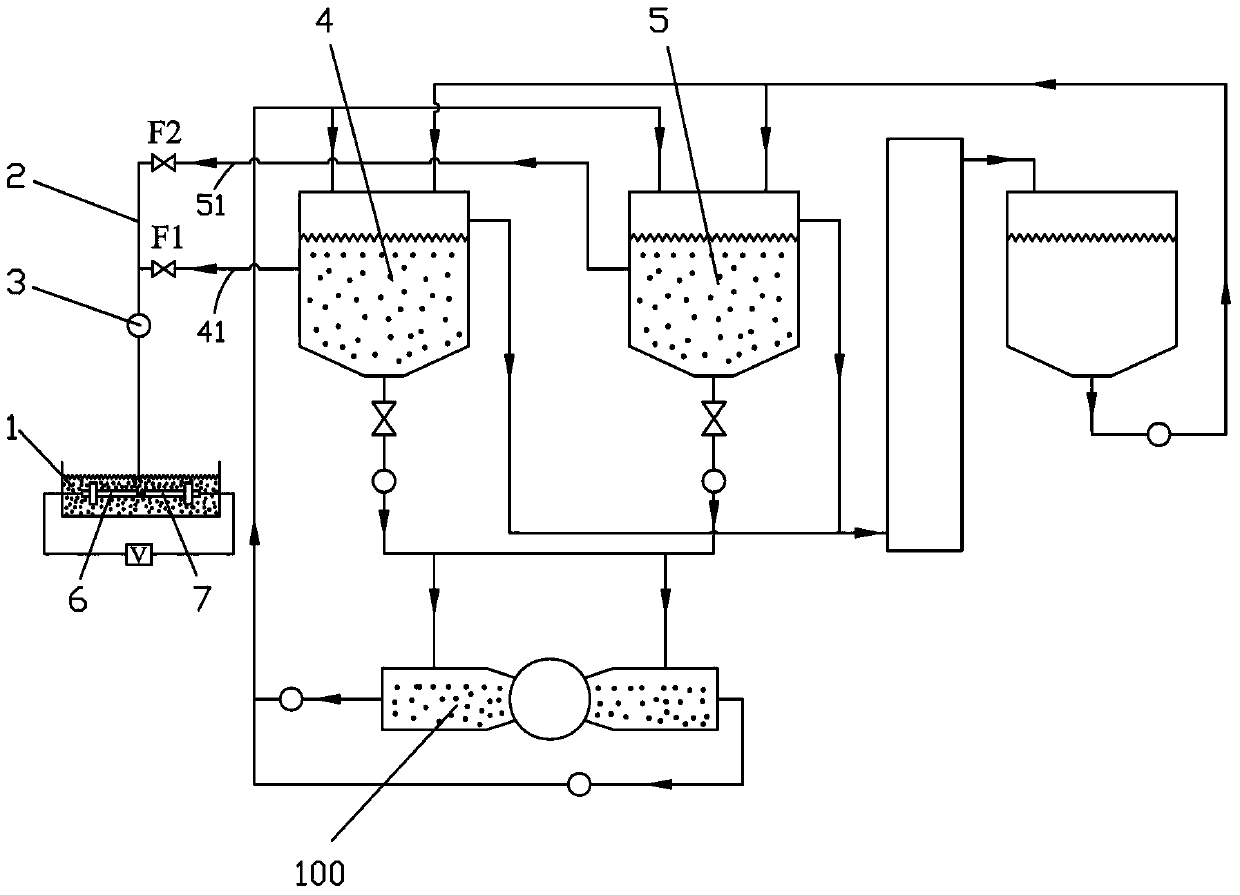

[0069] Taking the case where the target concentration of graphite in the insulating oil tank is 1.2%, and the concentration is 1.2% when 8 kg of graphite is added to the insulating oil tank as an example, the specific implementation methods are as follows:

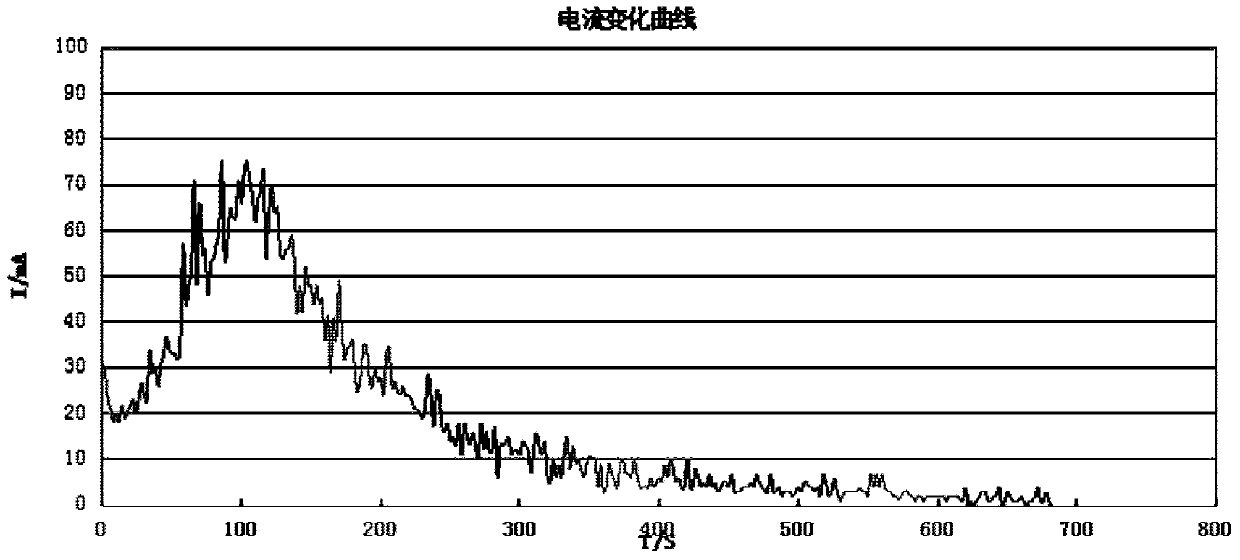

[0070] When the roll EDM texturing equipment is texturing the roll, the insulating oil tank 4 supplies the medium liquid to the roll roughing station 100, while the insulating oil tank 5 is in the filtering state. According to the general situation, the insulating oil tank is used for 32 hours, but the actual production time After the insulating oil tank is used for about 10 hours, when the roughness of the roughness is 1.6μm, the electrodes often vibrate and the electrodes are short-circuited.

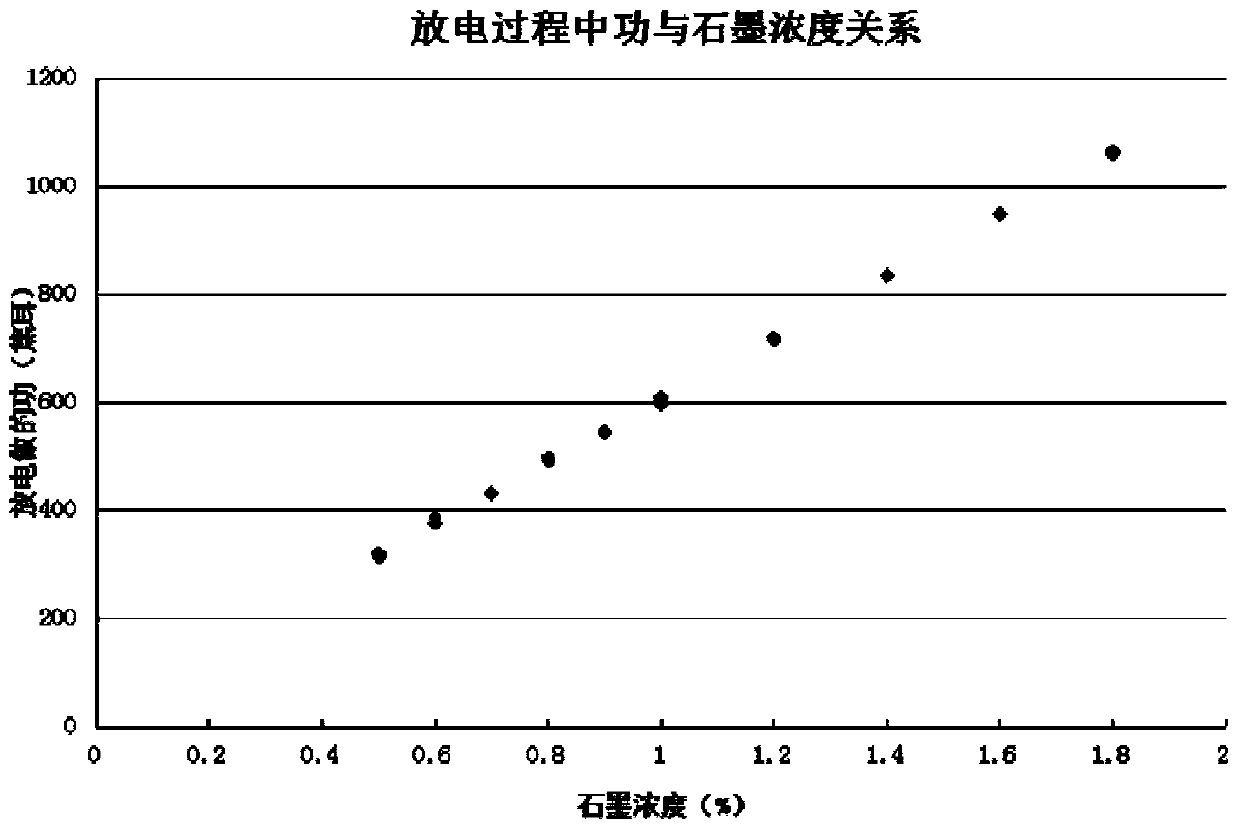

[0071] Utilize graphite concentration measuring device of the present invention, extract 0.5 liters of dielectric liquid from insulating oil tank 4, adjust the spacing between two electrodes 6,7 in graphite concentration measuring ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com