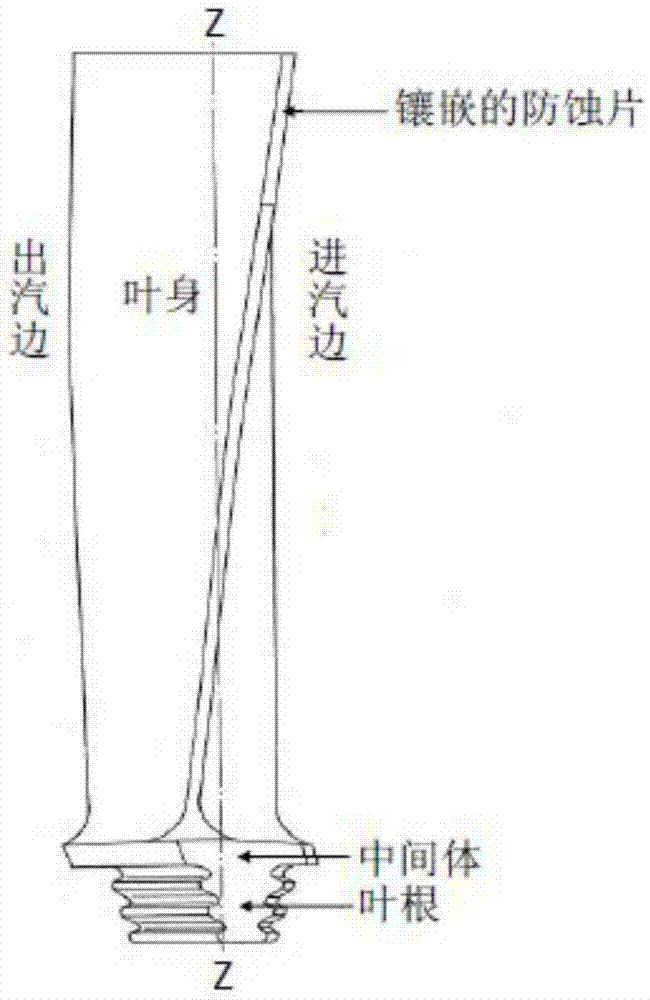

Ultrasonic phased array detection method for fir type blade roots of nuclear main turbine

An ultrasonic phased array, blade root technology, applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, measurement devices, etc. Complex structure and other problems, to achieve the effect of high defect detection rate, easy storage, and fast detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

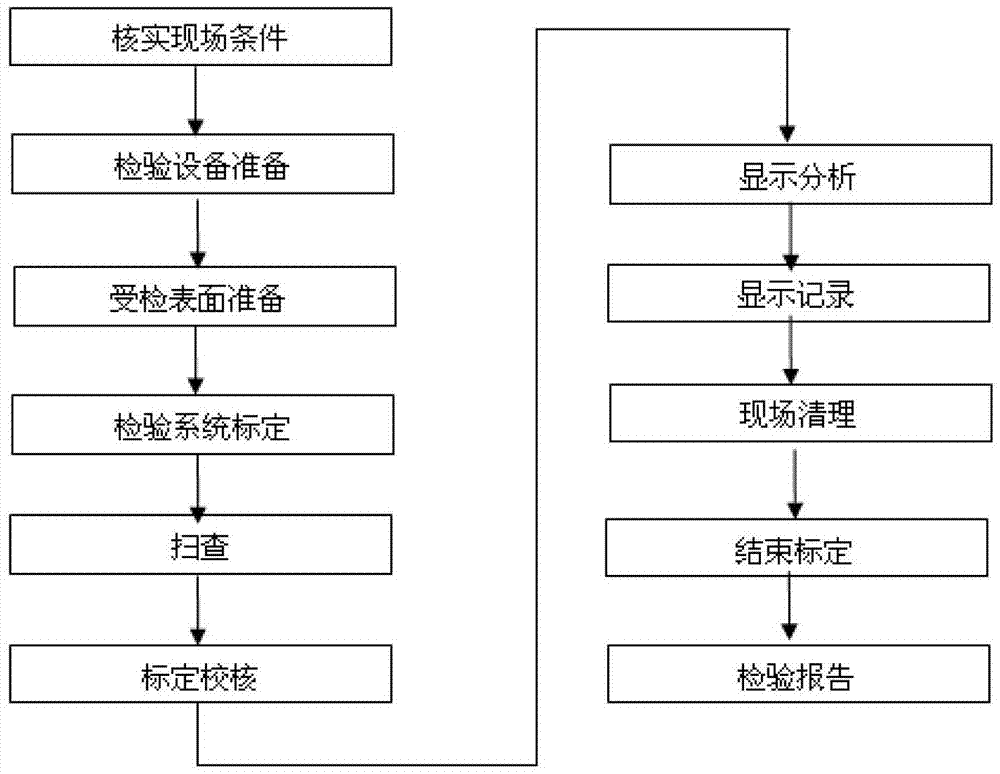

[0036] like figure 2 As shown, the ultrasonic phased array detection method for the fir-tree blade root of a nuclear power steam turbine specifically includes the following steps:

[0037] Step 1: System calibration;

[0038] Step 1.1: Test Instrument Performance

[0039] Before system calibration or re-calibration, test the vertical linearity and horizontal linearity of the phased array ultrasonic instrument. It is required that the vertical linearity error of the phased array ultrasonic instrument should not exceed 5%, and the horizontal linearity error should not exceed 2%.

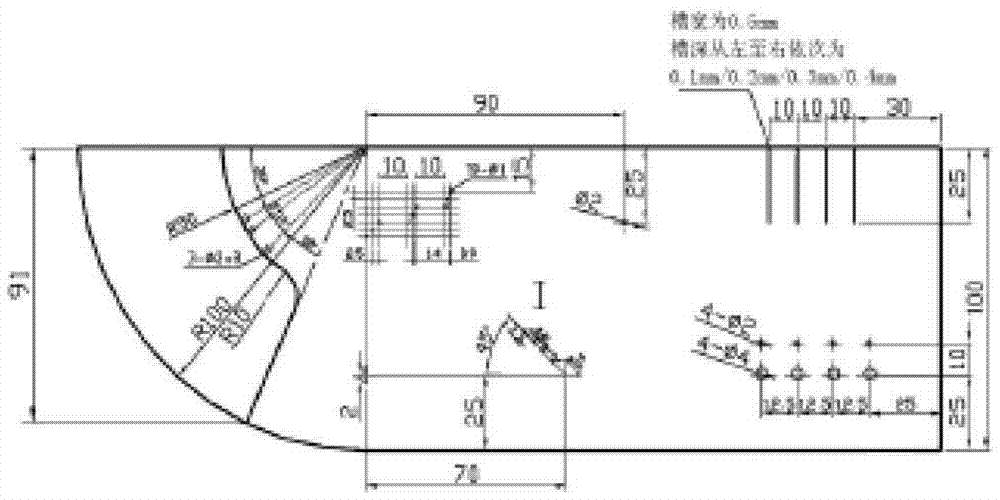

[0040] Step 1.2: Sensitivity Setting

[0041] First, complete the probe delay and angle gain compensation calibration on the R100 arc of the standard test block; then find the maximum amplitude of the corresponding 1.5mm deep crescent groove on the reference test block, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com