Electromagnetic damping device for wheel hub motor of electric automobile

A technology of in-wheel motor and shock absorption device, which is applied in electric vehicles, motor control, motors and other directions, can solve the problems of electromagnetic torque affecting the tangential direction, electromagnetic torque pulsation of in-wheel motor, small physical deformation of bearings, etc., to achieve real-time compensation, Improve smoothness and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

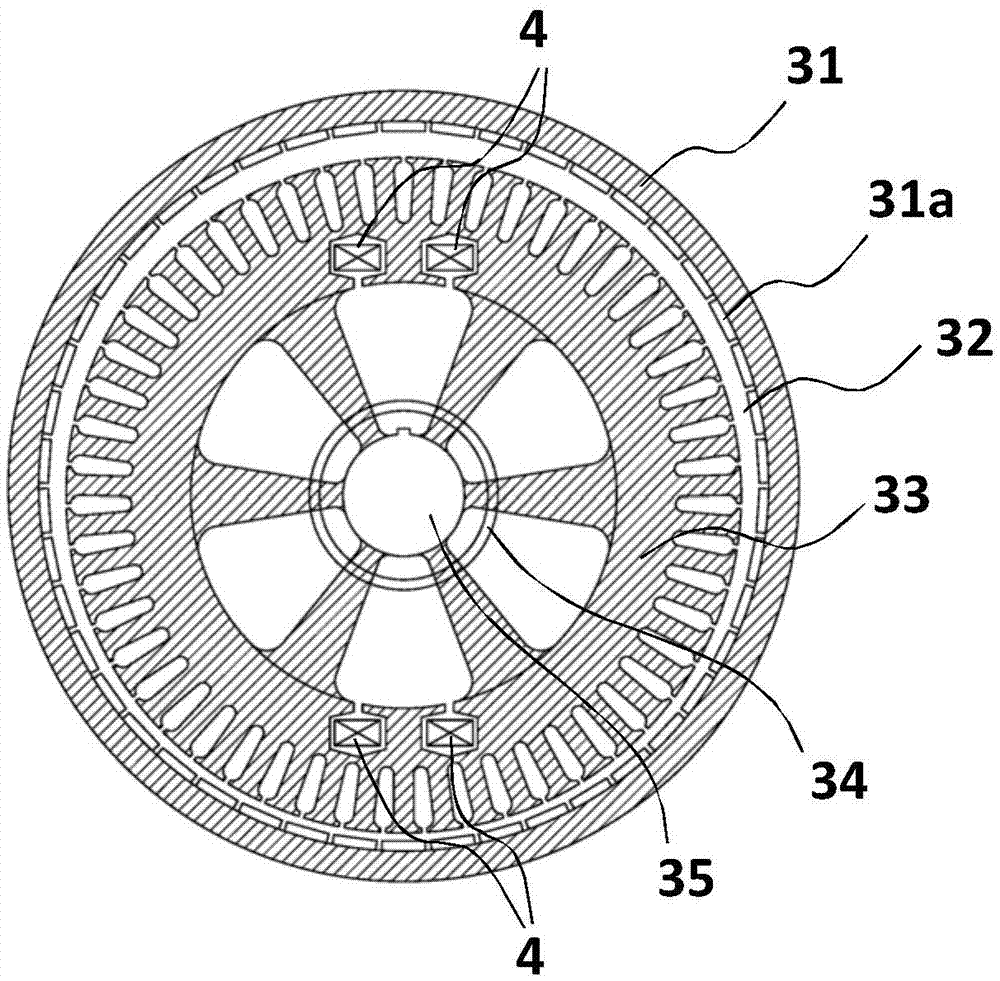

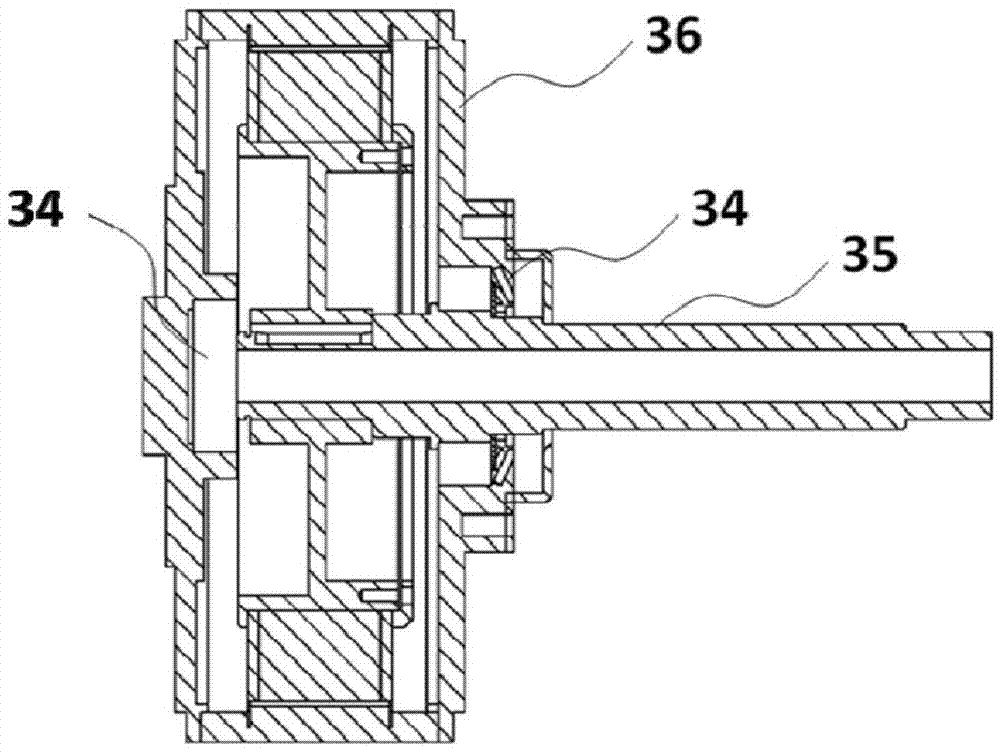

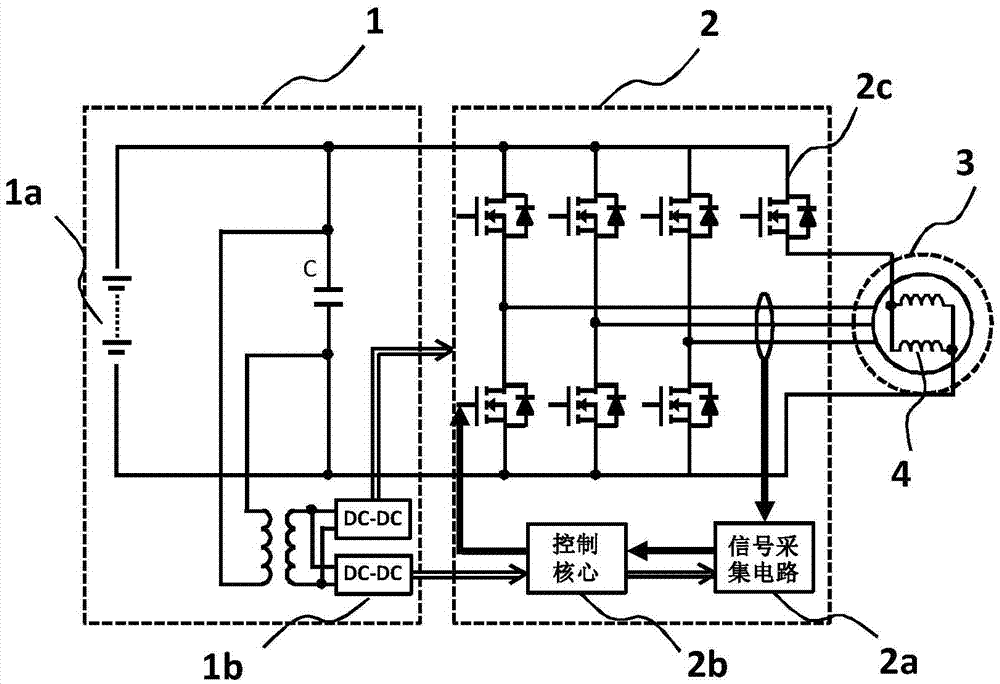

[0027] like Figure 1 to Figure 4 As shown, a hub motor electromagnetic damping device for an electric vehicle includes a vehicle power supply 1, a signal acquisition circuit 2a, a core control unit 2b, a drive circuit 2c and a hub motor 3, and the hub motor 3 includes an outer rotor 31, an inner stator 33, Bearing 34, motor shaft 35 and end cover 36, the inner stator 33 is arranged on the inner circumference of the outer rotor 31, the end cover 36 is fixedly connected with the outer rotor 31, the inner stator 33 is fixedly connected with the motor shaft 35, and the end cover 36 is provided with a bearing 34 , the motor shaft 35 is connected with the bearing 34. The inner peripheral surface of the outer rotor 31 is provided with a permanent magnet 31a. There is an air gap 32 between the outer peripheral surfaces of 33. When the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com