Soil working machine with straw returning-soil condition

A soil preparation machine and conditional technology, applied in the direction of soil preparation machinery, agricultural machinery and implements, applications, etc., can solve the problems of multiple rolling times, multiple operations, and affecting the quality and yield of wheat seedlings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

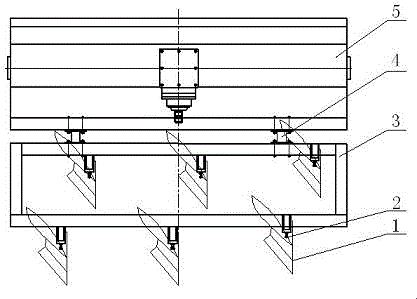

[0008] Such as figure 1 As shown, 1 is a plow body, 3 is a plow frame, 2 is a fixing bolt, 4 is a connecting piece, and 5 is a rotary tiller. Depend on figure 1 It can be seen that two plow bodies (1) are staggered forward and backward to form a plow body group, and 2-4 plow body groups are evenly arranged horizontally on the plow frame (3). The plow body (1) is connected to the plow frame (3) through fixing bolts (2), and the plow body (1) can be adjusted up and down. The rotary cultivating body is connected with the plow frame (3) through the connecting piece (4) and placed behind the plow frame. When the soil preparation machine works under the condition of straw returning to the field, the plow plows the soil and presses the straw under the soil at the same time, and the knife shaft of the rotary tiller is driven by the power output shaft of the tractor to rake the plowed soil.

[0009] Finally, it should be noted that: the above embodiments are only used to illustrate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com