Convenient mechanical jacket overturning and discharging parching cylinder

A mechanical, jacketed technology, applied in the field of chicken nuggets production equipment, can solve the problems of uneven color of chicken nuggets, difficult temperature control, time-consuming and labor-intensive, etc., and achieves the effects of simple structure, low heating cost, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

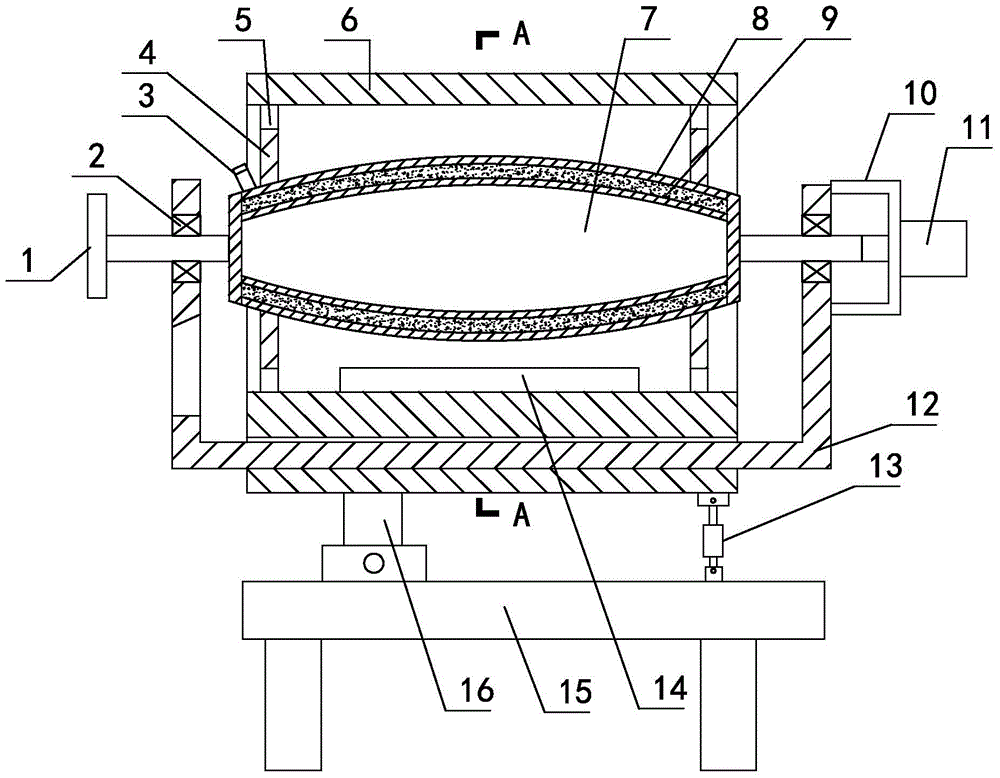

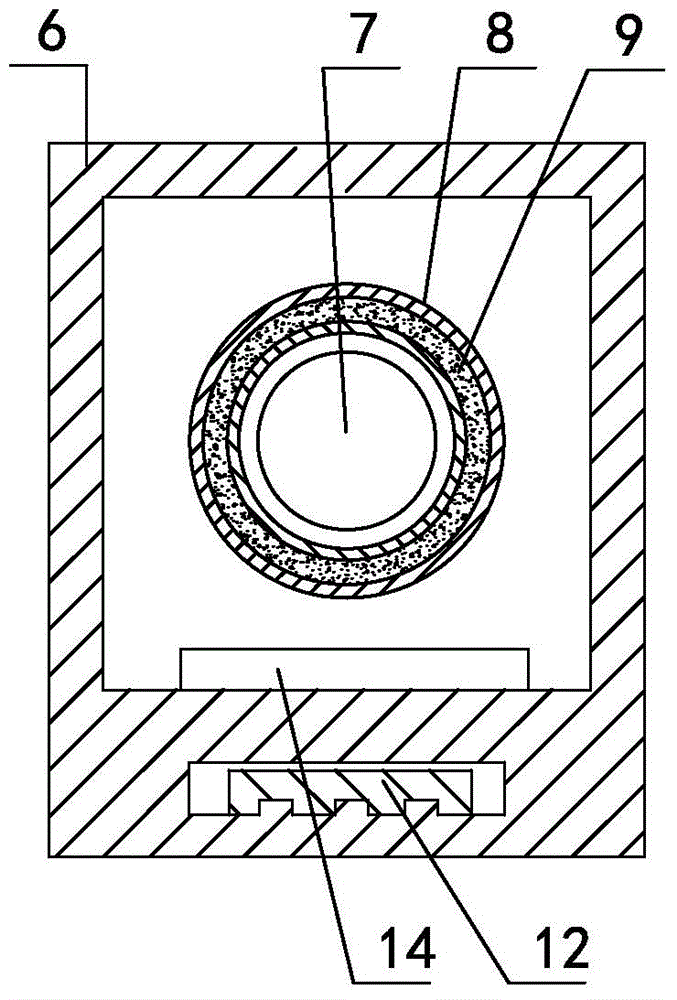

[0016] Such as figure 1 , figure 2 As shown, the convenient mechanical jacket flipping and unloading frying drum includes a worktable 15, a box body 6 with open ends and a tube body 7 for baking. The tube body 7 is horizontally arranged in the box body 6, and the tube body 7 The left side is provided with a feeding port 3, the left and right sides of the cylinder body 7 are respectively horizontally fixed with a rotating shaft, and the rotating shaft is mounted on the sliding frame 12 through the bearing 2. The bottom of the body 6 is in a sliding fit with the box body 6. The left end of the left rotating shaft is equipped with a handle plate 1 for manual rotation of the rotating shaft, and the right end of the right rotating shaft is installed with a motor 11 for rotating the rotating shaft. Motor 11 The mounting frame 10 is installed on the sliding frame 12, a jacket 8 is provided on the outer surface of the cylinder 7, and the cylinder 7 and the jacket 8 form a closed cavit...

Embodiment 2

[0020] On the basis of Embodiment 1, the distance between the gas stove 14 and the jacket 9 is changed to 55 mm. Others are the same as in Example 1.

Embodiment 3

[0022] A change is made on the basis of Embodiment 1, and the distance between the gas stove 14 and the jacket 9 is changed to 60 mm. Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com