Chocolate packaging mechanism

A chocolate and packaging technology, applied in packaging, transportation packaging, packaging protection, etc., can solve the problems of low degree of automation, reduced automatic control ability, speed coordination, etc., to achieve high automation, avoid wrinkles, improve self-control ability and coordination effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

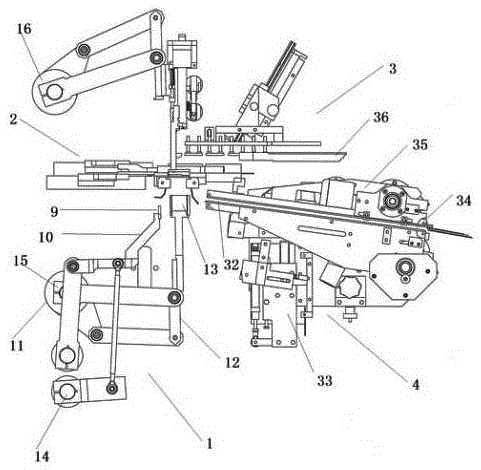

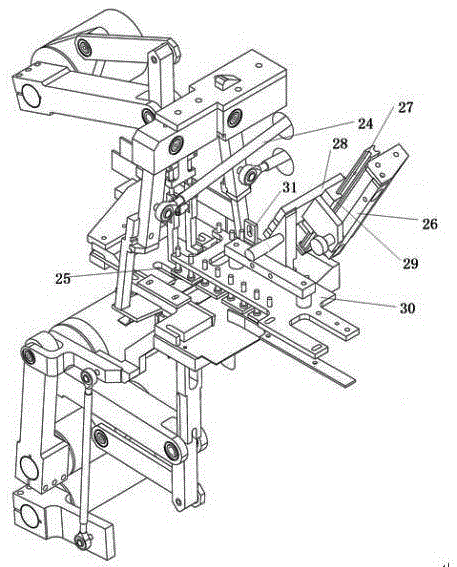

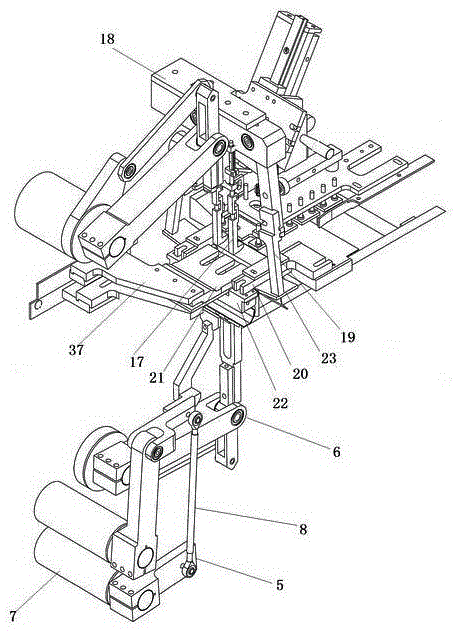

[0020] like Figure 1 to Figure 3 A chocolate packaging mechanism is shown, which includes a chocolate transmission device 1, a packaging device 2, a control detection device 3 and a wrapping paper transmission device 4; the chocolate transmission device 1 is located under the packaging device 2, and the control detection device 3 is located under the packaging device On the right side of 2, the wrapping paper conveyor 4 is located on the right side of the chocolate transmission 1;

[0021] The chocolate transmission device 1 includes a front dial transmission mechanism 5 and a push-up transmission mechanism 6; the front dial transmission mechanism 5 includes a transmission shaft 7, a connecting rod 8, a shifting block 9 and a front shifting arm 10; a transmission shaft 7 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com