Beam structure for installing tube and groove type sulfuric acid distributing device

A technology of acid divider and beam structure, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of inconvenient horizontal position adjustment, affecting the service life of installed parts, affecting the effect of acid separation, etc., to achieve Simple installation structure, long service life and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

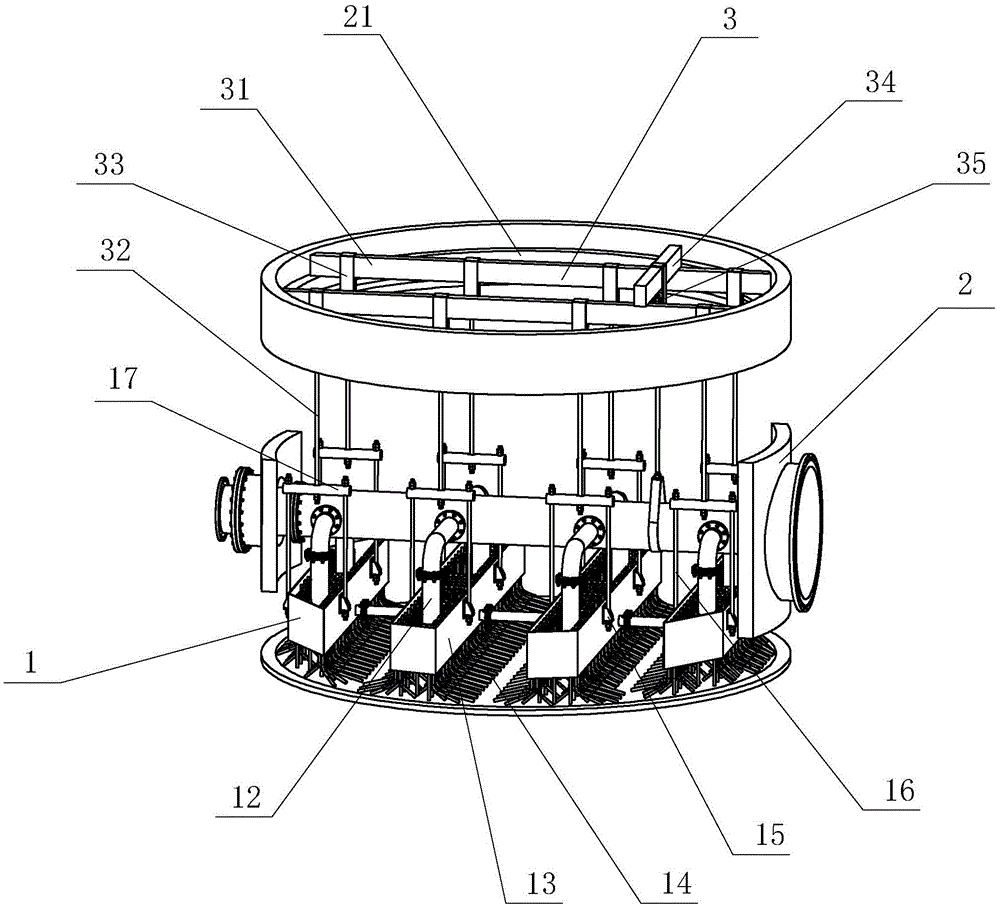

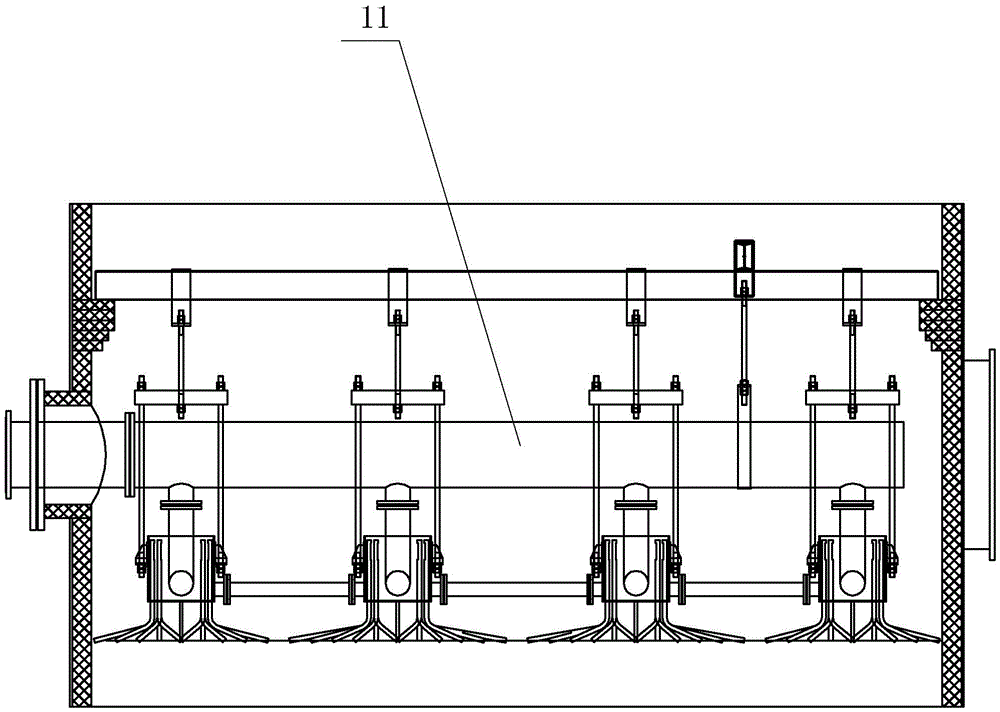

[0025] Such as figure 1 combine figure 2 As shown, a beam structure for installing a pipe-trough acid distributor, including an acid distributor 1, a tower body 2 and an installation part 3 for installing the acid distributor,

[0026] The acid distributor 1 includes an acid main pipe 11, an acid branch pipe 12, an acid distribution tank 13 and an acid drop pipe 14. The two sides of the acid distribution tank 13 are provided with mutually symmetrical lifting lugs 15, and these lifting lugs 15 are connected with the lower Suspenders 16, every two mutually symmetrical lower suspenders 16 are connected by pole steel 17;

[0027] Tower body 2, an upper brick platform 21 is provided at the inner edge of the upper part of the tower body;

[0028] The installation part 3 includes two side beams 31 suspended in parallel on the upper brick platform 21, and severa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com