Method for preparing cyclopentanone through dehydrogenation of cyclopentanol

A technology of cyclopentanone and cyclopentanol, which is applied in the field of cyclopentanone dehydrogenation to prepare cyclopentanone, can solve the problems of high energy consumption and low catalyst efficiency, and achieve the effect of improving reaction efficiency and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

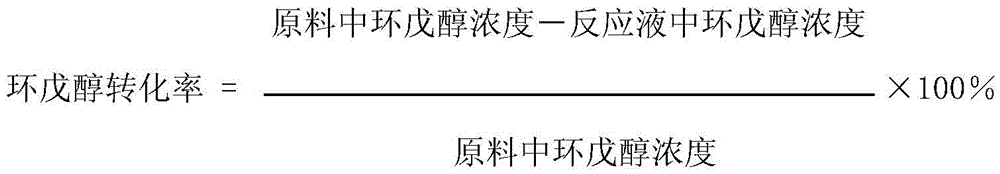

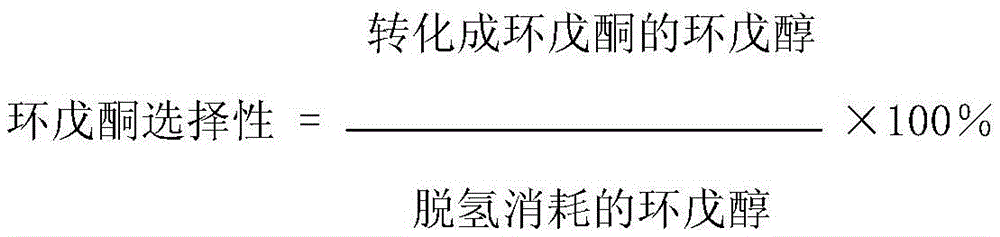

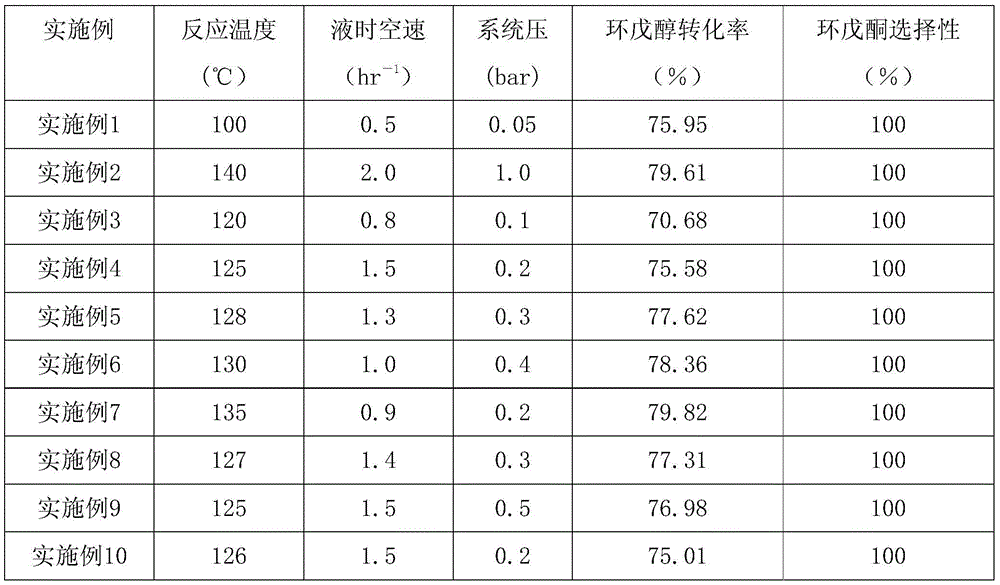

[0016] The dehydrogenation reactor is a stainless steel tubular reactor with a size of φ25mm×1000mm, and 100ml of catalyst is filled in the reaction tube. The catalyst uses Ni and Cu as active components, Al 2 o 3 with SiO 2 The mixture is used as a carrier, the content of Ni is 30-50wt%, and the content of Cu is 1-5wt%. The bottom of the reactor is filled with inert ceramic balls. After the dehydrogenation raw material is preheated, the pump enters the reactor from the top through the distributor at a set rate to carry out the dehydrogenation reaction. The dehydrogenation material enters a gas-liquid separator from the bottom of the dehydrogenation reactor, and the liquid phase material enters the product storage tank. The system pressure is controlled by the hydrogen regulating valve separated from the gas-liquid separator. The cyclopentanol conversion and cyclopentanone selectivity of concrete reaction conditions, dehydrogenation reaction are listed in Table 1.

[0017...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com