Integrated anti-explosion networked intelligent inspection well lid

A manhole cover and integrated technology, which is applied in the field of integrated explosion-proof networked intelligent manhole covers, can solve the problems that gas detectors cannot be monitored in real time, gas detection sensitivity is not high, waterproof safety is not enough, etc., and achieves novel structure design, The effect of small environmental influence factors and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below according to accompanying drawing and specific embodiment, the present invention will be further described:

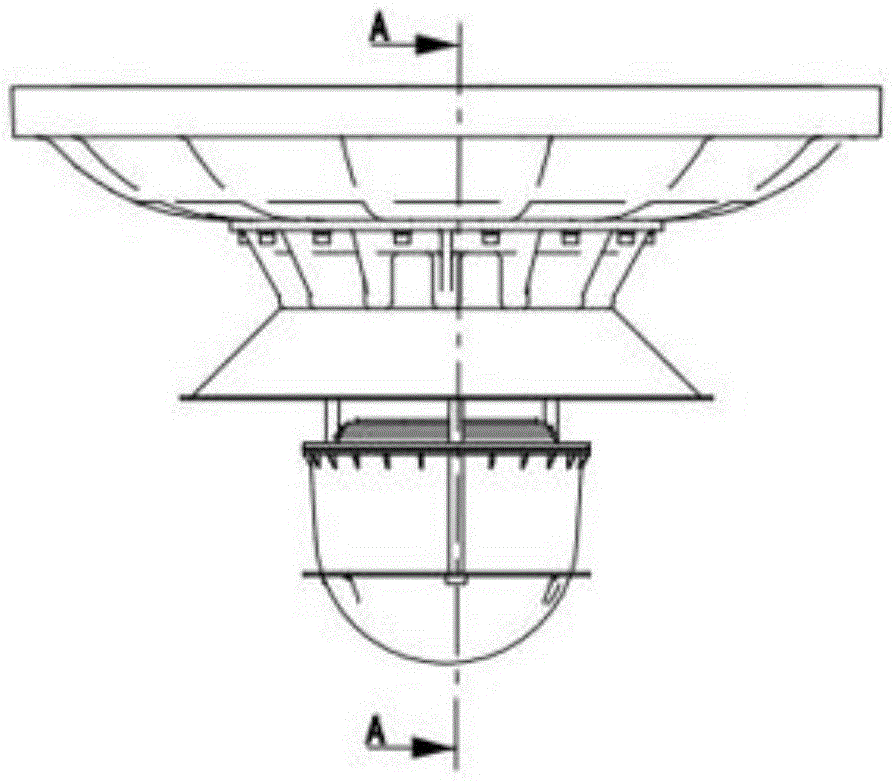

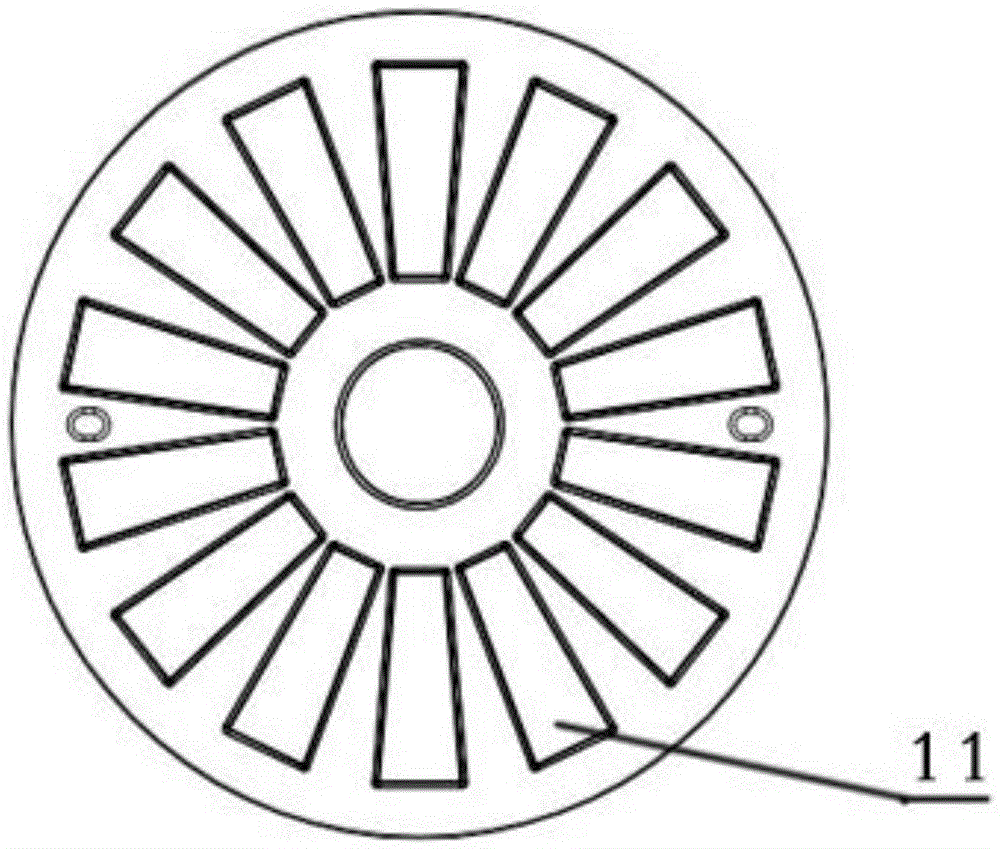

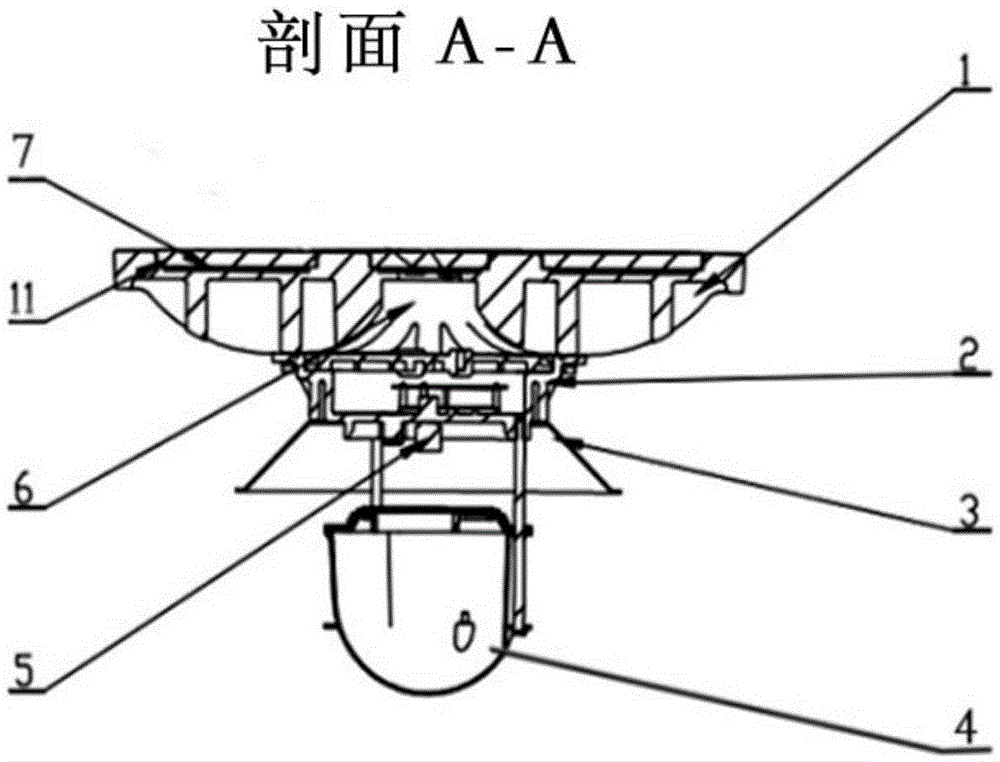

[0036] Such as Figure 1-7 As shown, an integrated explosion-proof networked smart manhole cover of the present invention includes a manhole cover 1 and an explosion-proof box 2 placed under the manhole cover 1, and the explosion-proof box 2 and the manhole cover 1 are sealed and fixed to form a sealed cavity 6. An MCU processor, a GPS / Beidou positioning module connected to the MCU processor, a CDMA / GPRS communication module, an RS232 serial port and a lithium battery are installed in the explosion-proof box 2. The upper plane of the manhole cover 1 is evenly equipped with several Groove, the solar battery panel 7 matching with the size of the groove is placed in the groove, the solar battery panel is a trapezoidal thickness transparent part 11, that is, a high-strength anti-scratch resin, which protects the solar panel and covers a high-strength anti-scra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com